Paint spraying bucket cleaning device and cleaning method thereof

A technology for cleaning equipment and containers, applied in the field of paint bucket cleaning, which can solve problems such as low cleaning efficiency, achieve the effects of reducing labor intensity, preventing corrosion, and improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details. Known components, methods and processes will not be described in detail below.

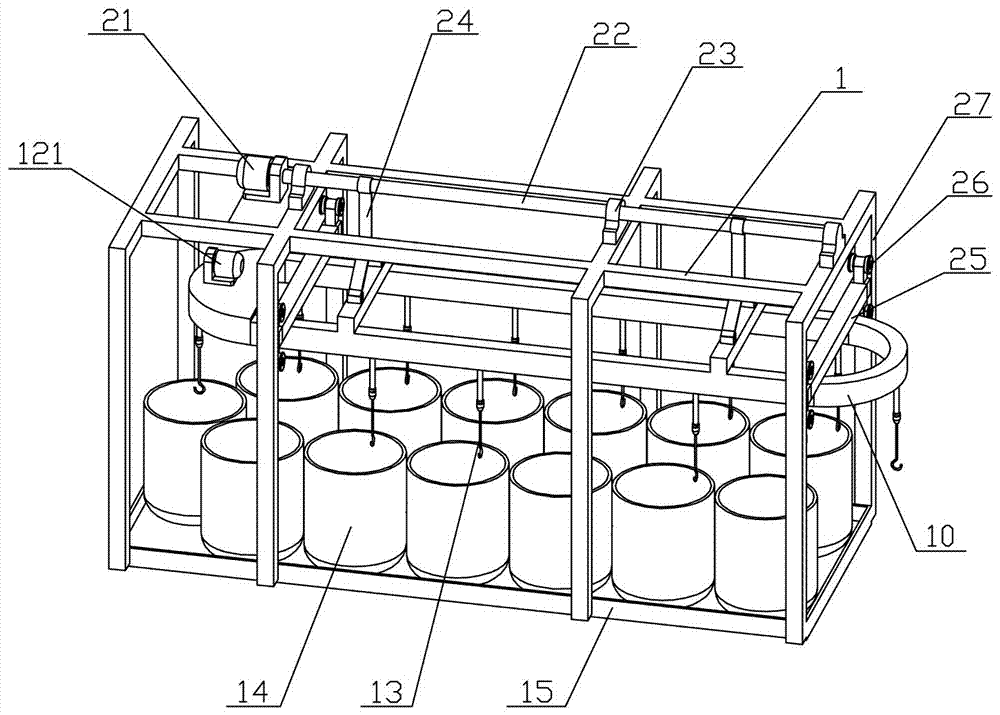

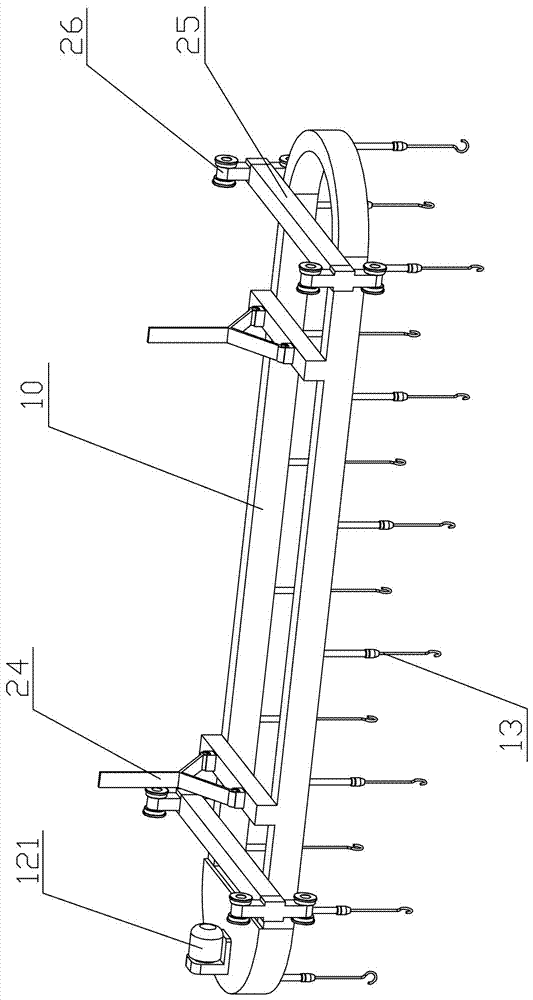

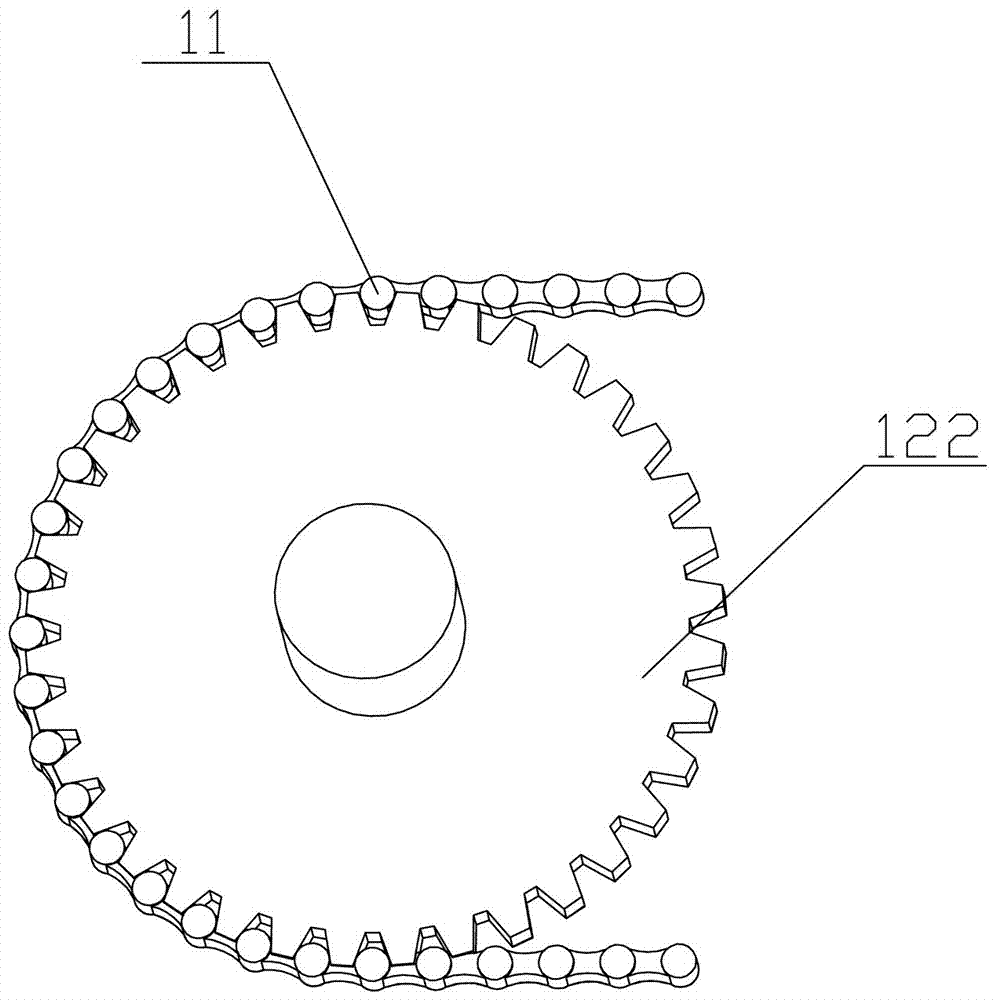

[0028] A kind of cleaning equipment of paint bucket, refer to Figure 1 to Figure 3 , including a bracket 1, the upper part of the bracket 1 is provided with a closed circular track 10, the circular track 10 is provided with an endless chain 11 and a chain driving mechanism, the chain driving mechanism includes a rotating motor 121 and a rotating Disk 122, the inner peripheral side wall of the annular track 10 has a notch (not shown in the figure), the rotating disk 122 is arranged on the side of the notch and engages with the endless chain 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com