Automatic pressing device of split pins

A press-fitting device and split pin technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of product mixing, mixing, and low efficiency, so as to improve product assembly accuracy, reduce labor, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

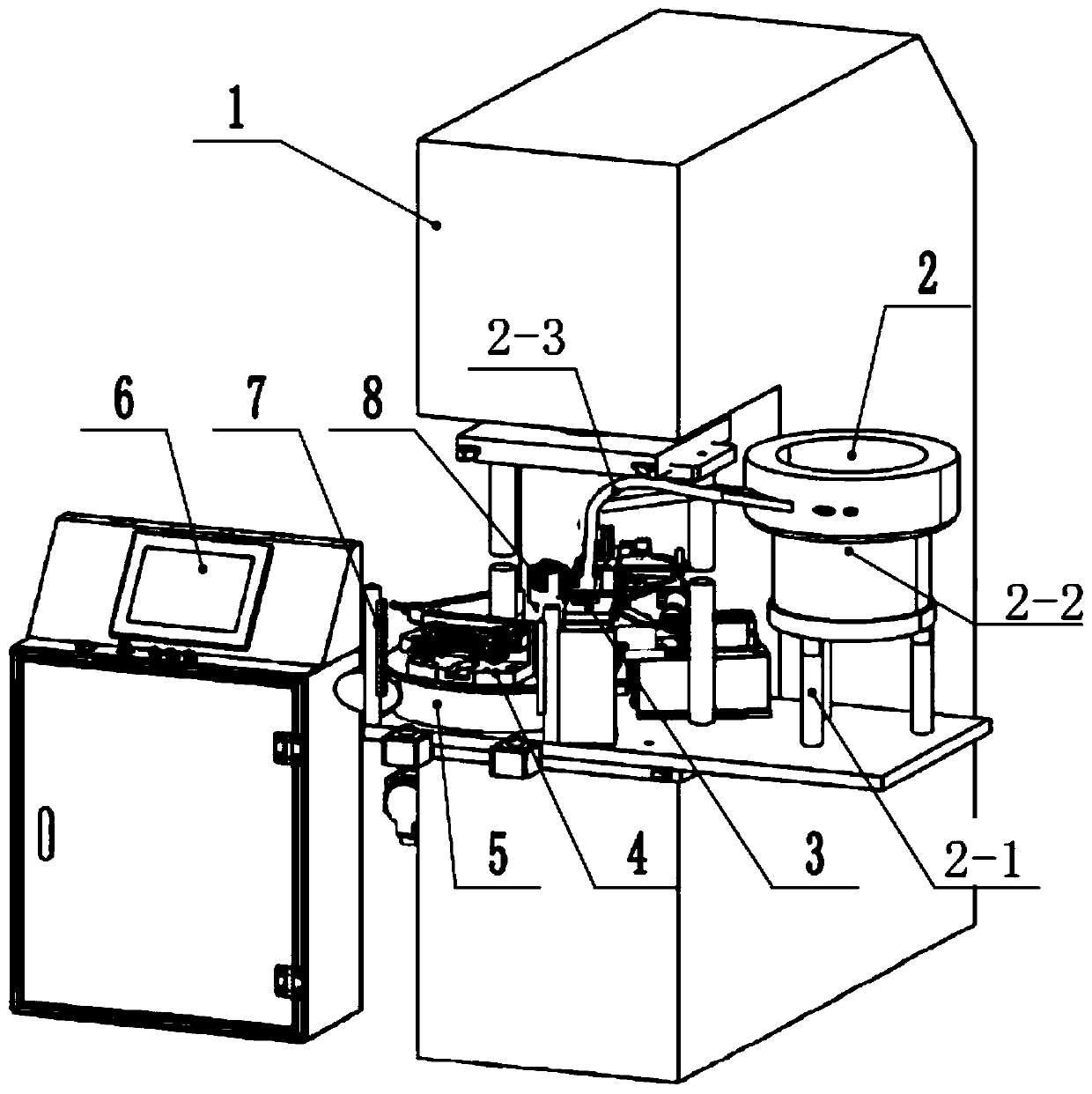

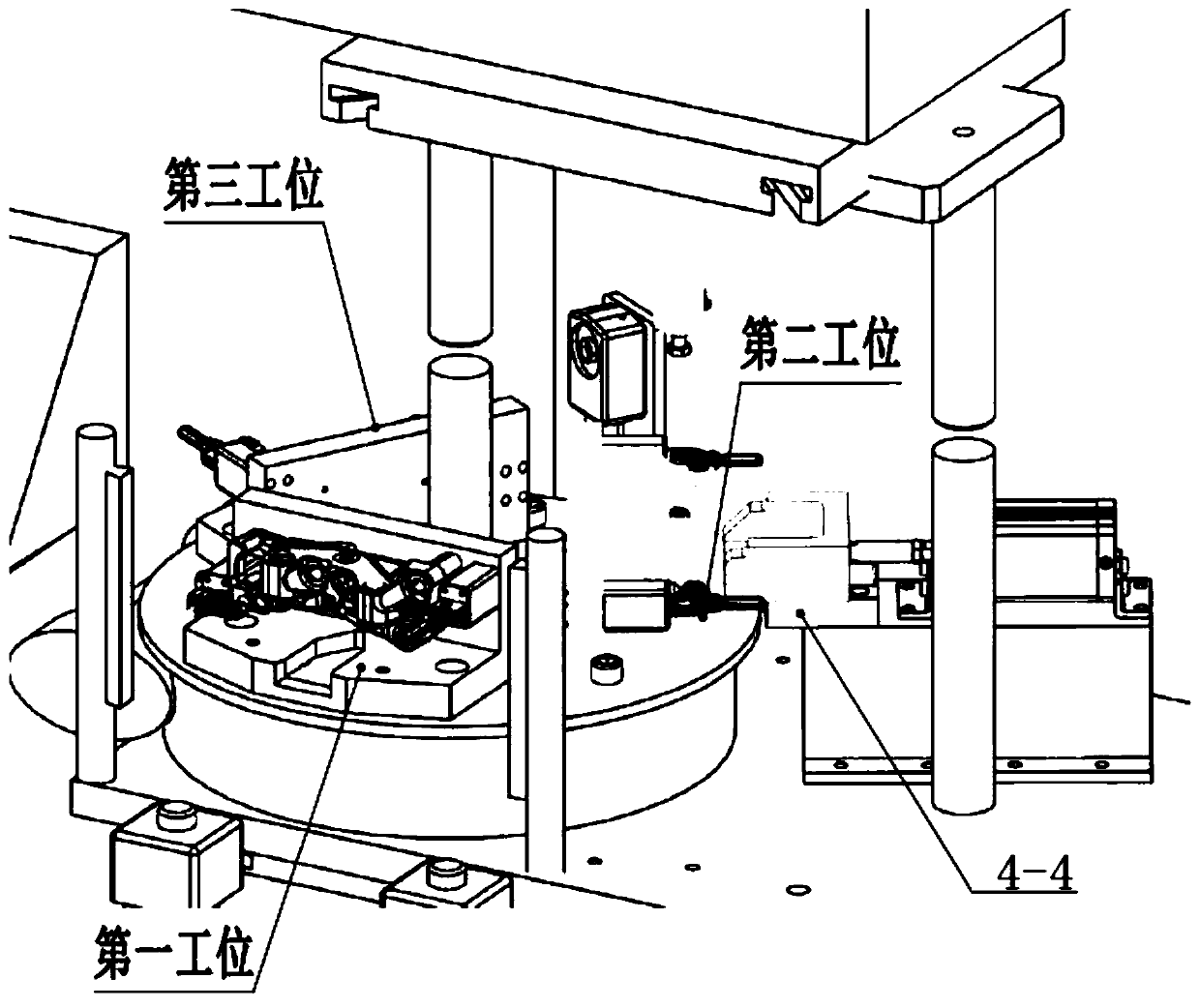

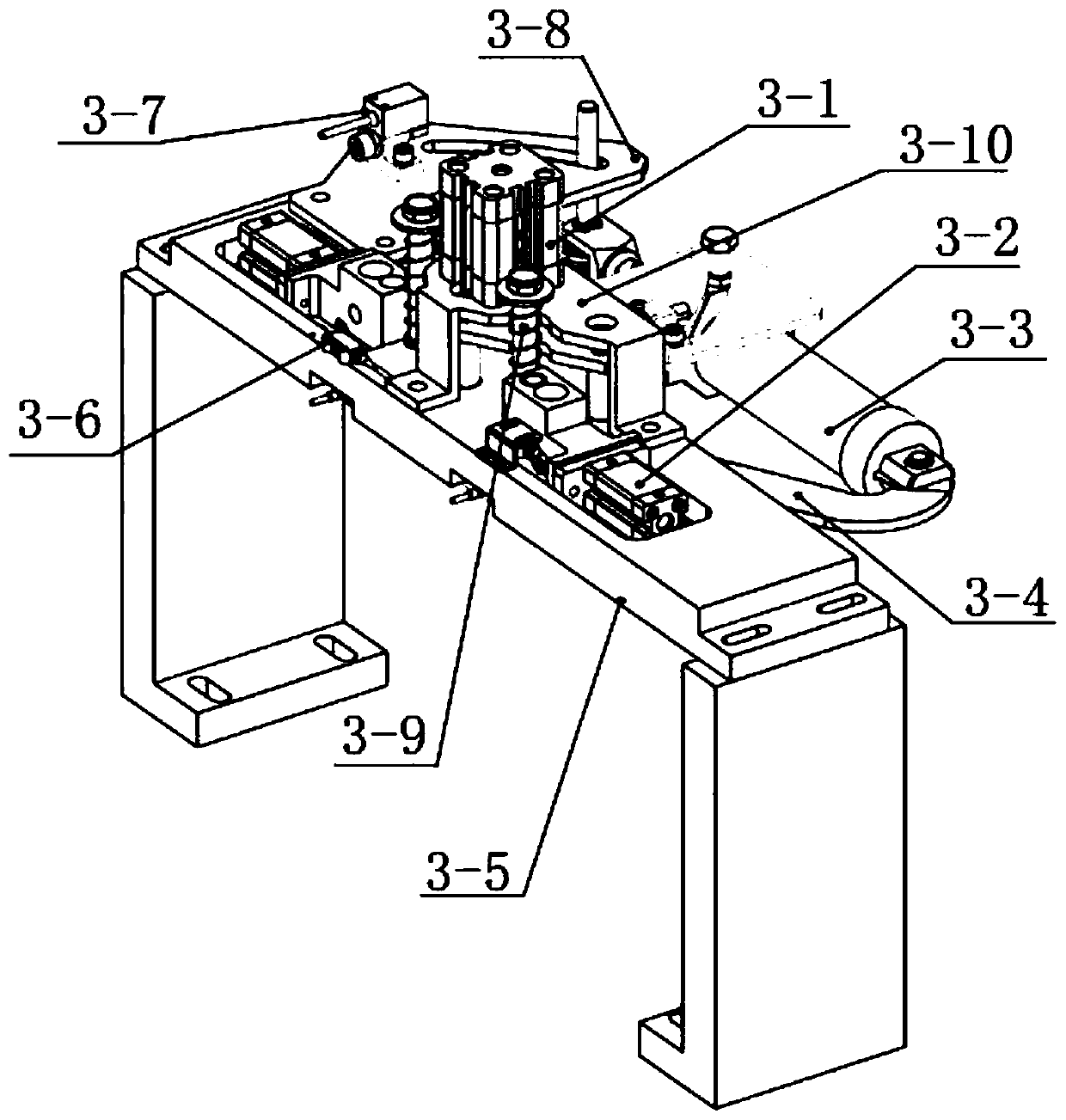

[0024] see Figure 1 to Figure 6 , and in conjunction with the abstract drawings, it describes an automatic press-fitting device for cotter pins of an automobile engine bracket. Mechanism 3, fixture part 4, servo index turntable part 5, electric control cabinet operation panel 6, safety grating part 7 and visual inspection device 8;

[0025] In this implementation case, the automatic feeder 2, the cotter pin pre-tightening mechanism 3, the servo indexing turntable part 5, the safety grating part 7, and the visual inspection device 8 are all installed on the table of the press machine 1;

[0026] The automatic feeder 2 includes an adjustment base 2-1, an automatic feeding mechanism 2-2, and a conveying pipeline track system 2-3; after the automatic feeding mechanism 2-2 automatically sorts the cotter pins of the automobile engine bracket, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com