Reverse limiting device for chain

A limit device and chain technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of aggravated chain wear, increased movement resistance, and inconvenient installation, so as to reduce wear, simplify structure, and install convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

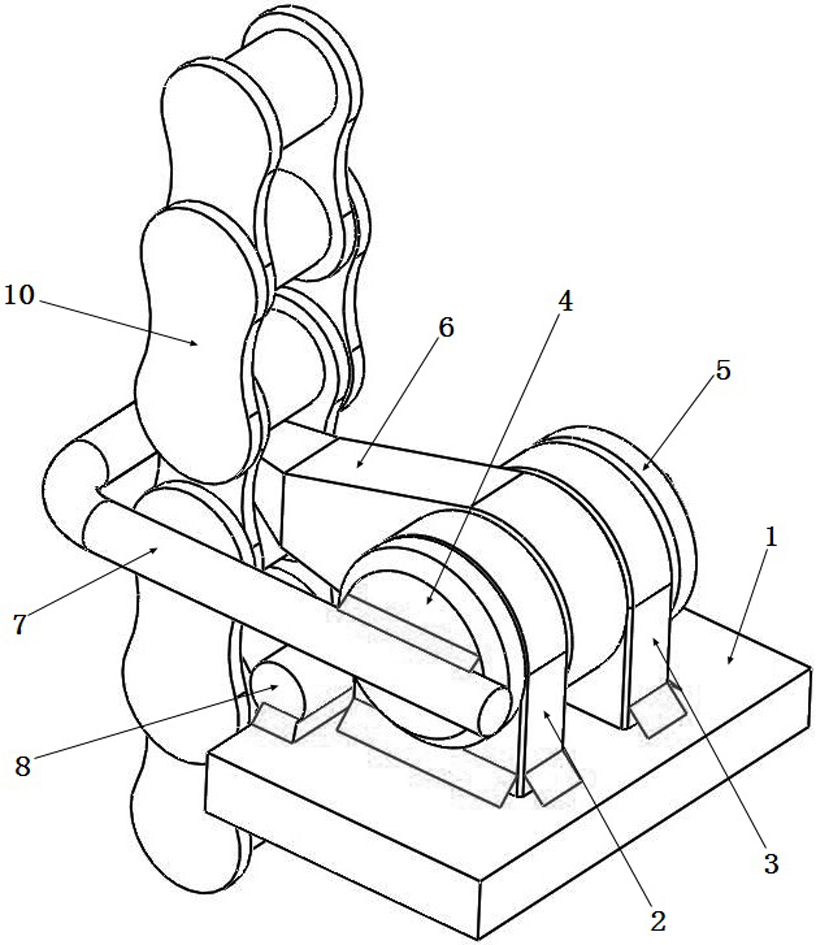

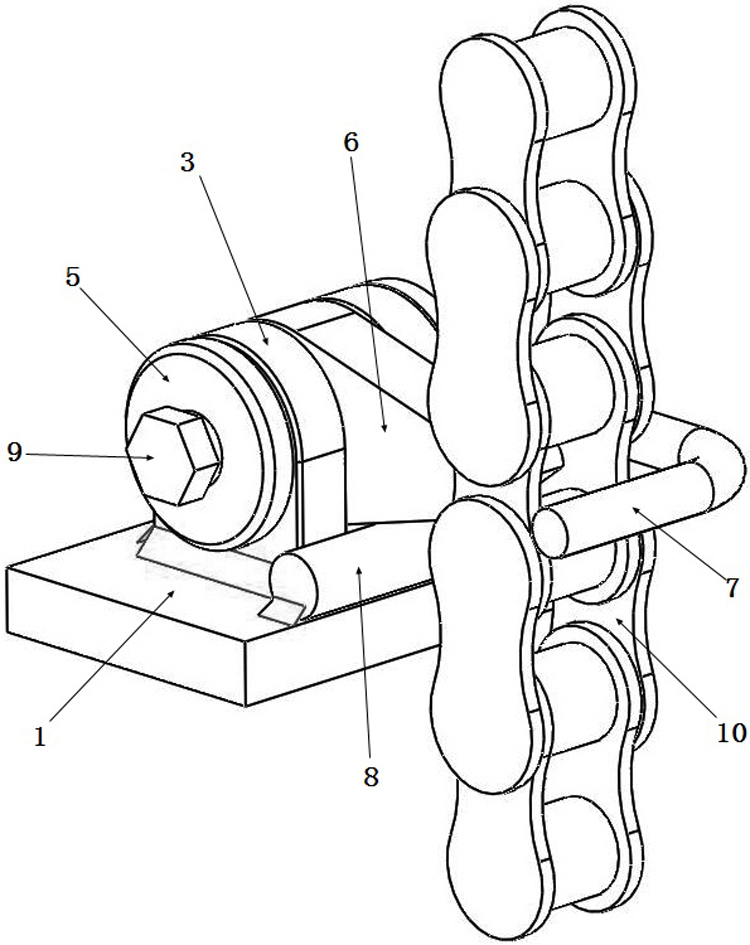

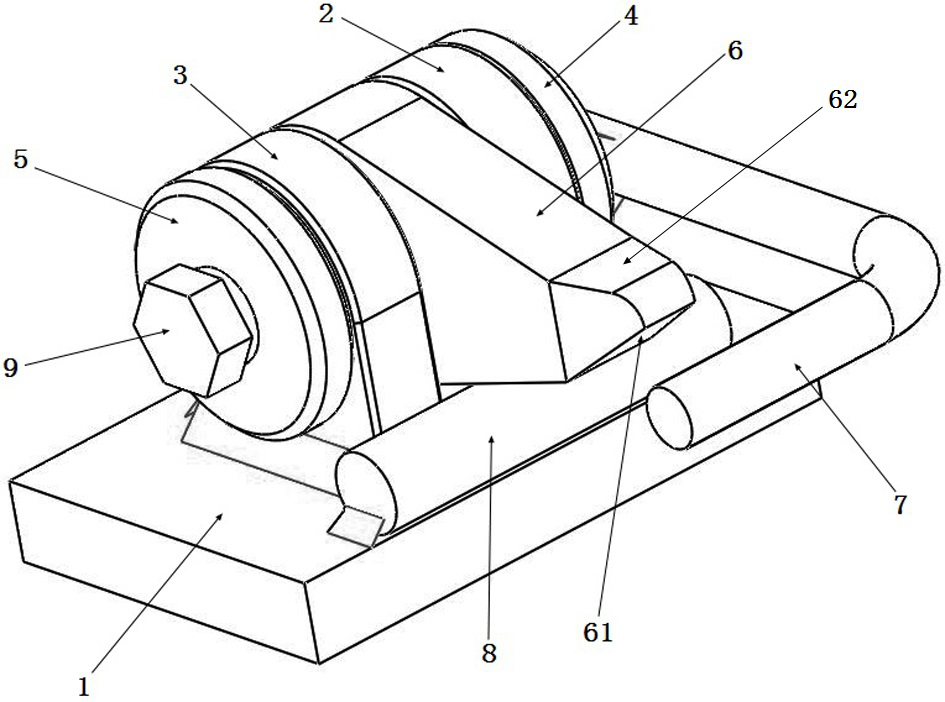

[0028] An embodiment of the chain reverse limiting device in the present invention is as Figure 1~Figure 6 As shown, it includes a base and a chain lock installed on the base that can be rotated at a certain rotation angle, wherein the base includes a base plate 1 used to be fixed on other equipment when in use and two parallel spaced sets that are welded and fixed on the base plate 1 The risers are respectively the left riser 2 and the right riser 3. Fixed shaft 4 is installed on left vertical board 2 and right vertical board 3, as Figure 6 As shown, the fixed shaft 4 is in the shape of a stepped shaft, the left end of which is a large end, and the right end is a small end. It is perforated, and its large end is matched with the side of the left vertical plate 2, and its small end is fixedly connected with the right vertical plate 3 by fasteners.

[0029] Specifically, a threaded hole is processed on the small end of the fixed shaft 4, and the end face of the small end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com