Track walking type minitype rice combine harvester

A combine harvester and walking technology, which is applied in the direction of harvesters, crawler vehicles, cutters, etc., can solve the problems of high labor intensity, low work efficiency, and difficulty in maintenance, so as to reduce labor intensity, improve work efficiency, The effect of easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

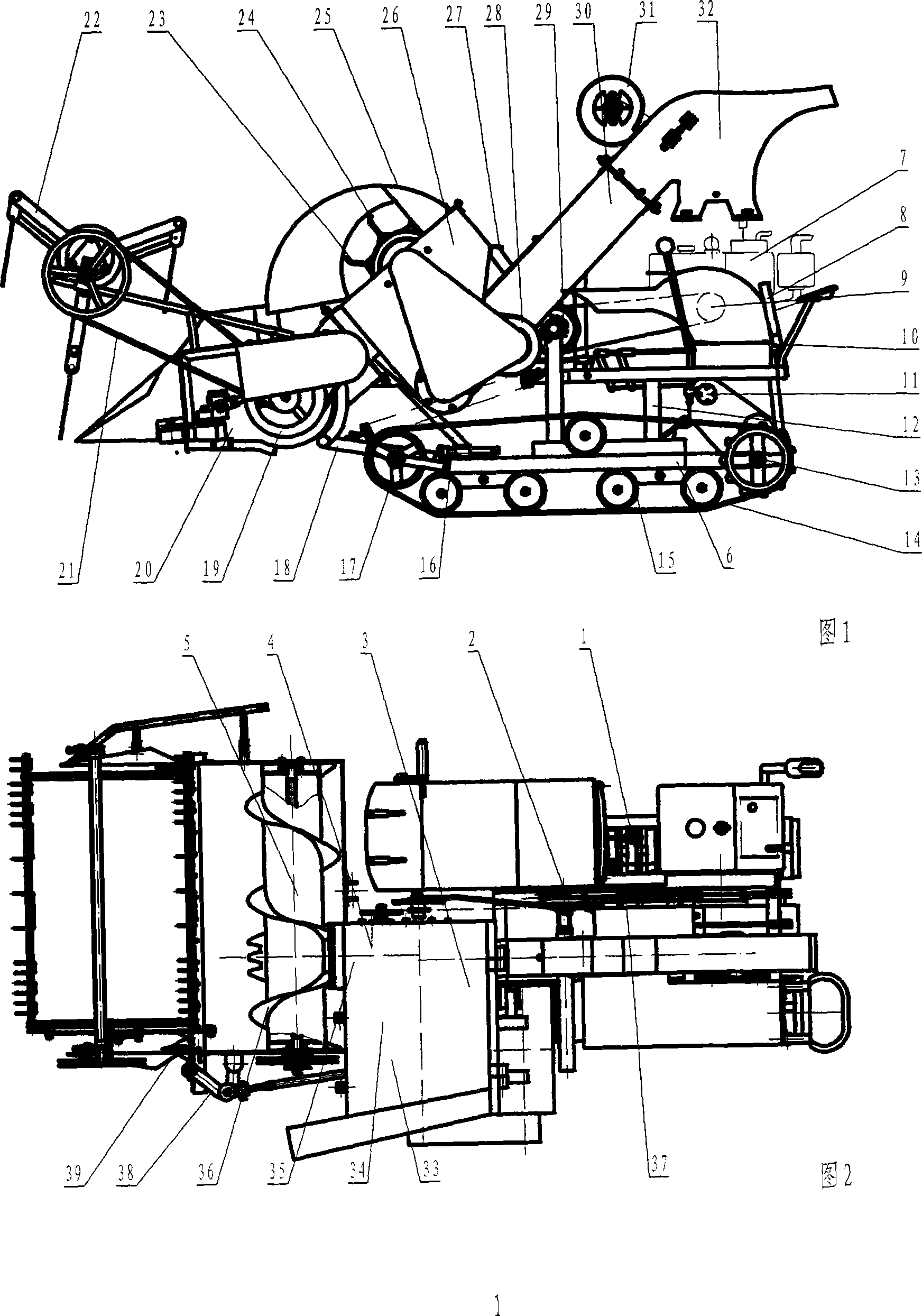

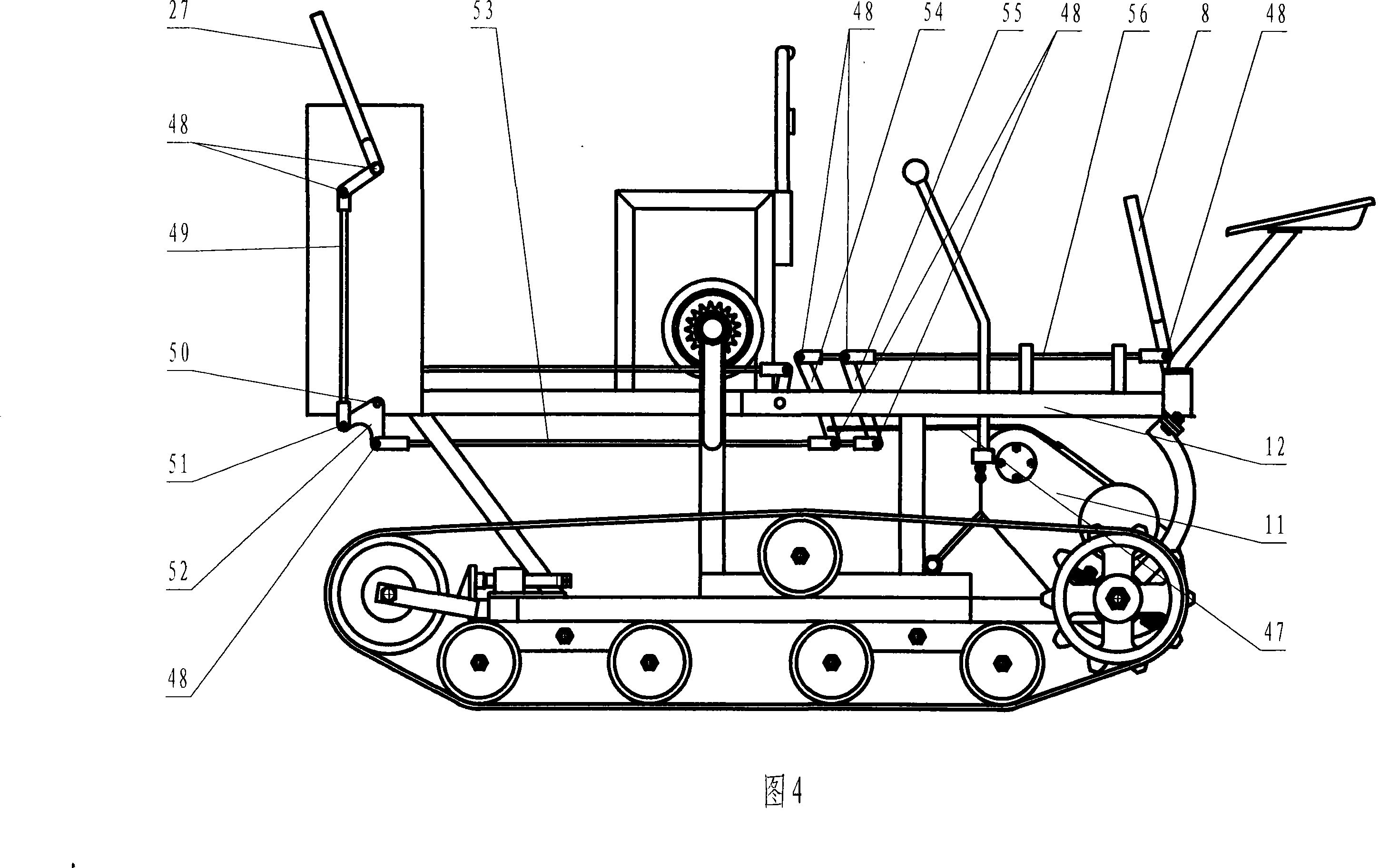

[0021] The crawler walking type mini rice combine harvester has a chassis 1, a traveling device 6, a transmission device 2, a conveying device 4, a harvesting device 5, and a threshing device 3.

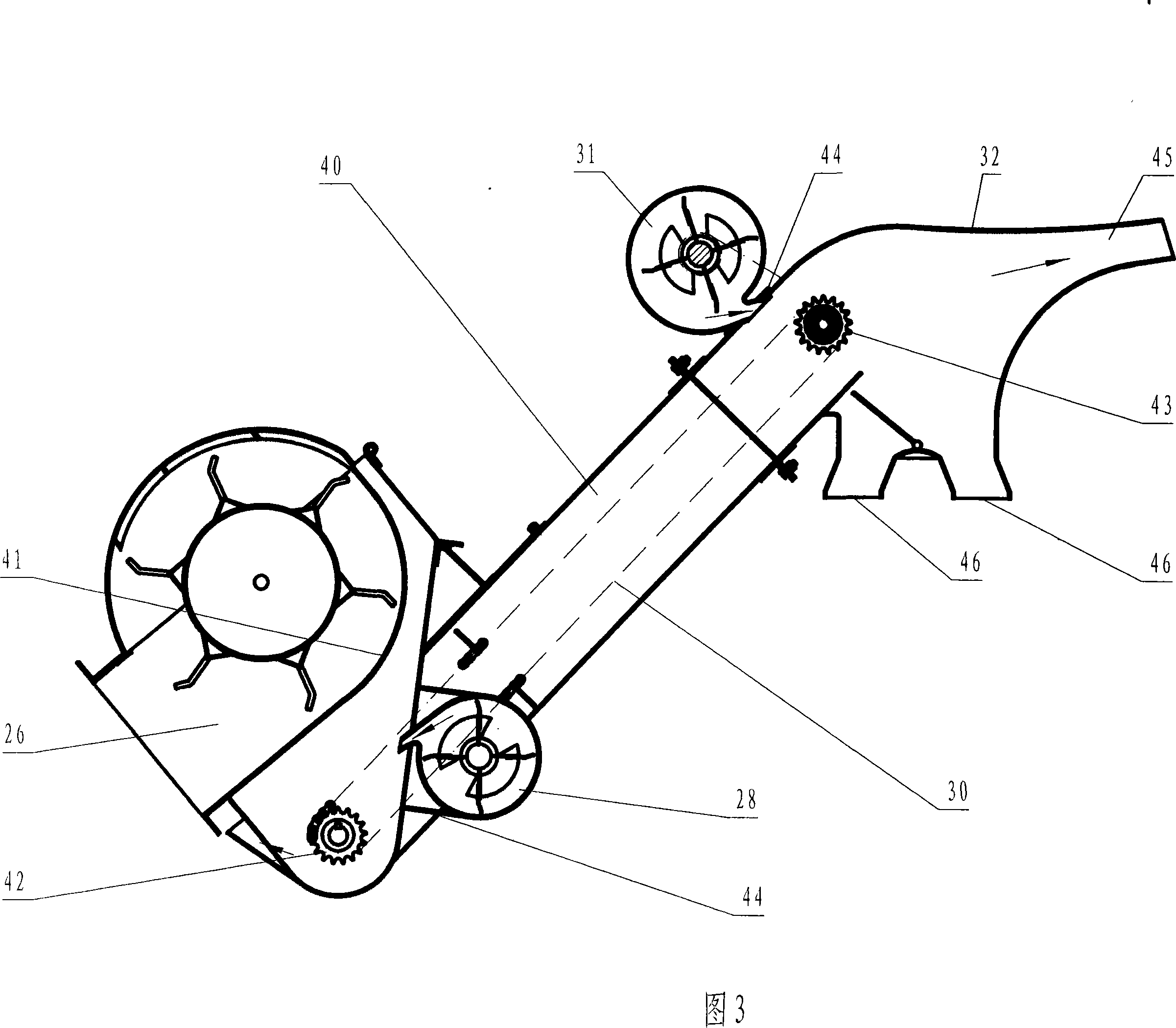

[0022] A chain scraper conveyor belt 30 is housed in the conveying cylinder 40 of the threshing device 3 . A fan 28 is installed below the threshing screen 41 at the inlet end of the chain scraper conveyor belt 30, and a fan 31 is installed above the outlet end of the chain scraper conveyor belt 30, and the storage bucket connected to the end of the delivery cylinder 30 is connected to the bottom of the valley device 32 There is a downward grain outlet 46, and a forward air outlet 45 is arranged on the top of the storage bucket connecting the grain device 32. The blower fan 28 and the blower fan 31 are respectively fixedly installed on the cylinder body of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com