Box type filter press side beam filter cloth washing car chain traveling mechanism and traveling mode

A box filter press and walking mechanism technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve problems such as unavoidable slippage, deformation of water washing walking track, and difficulty in gear meshing, and achieve the installation and docking ratio The rack and pinion are convenient, the structure is simple and compact, and the transmission stability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

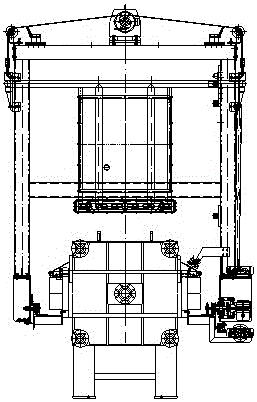

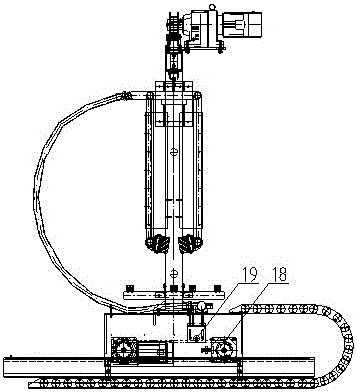

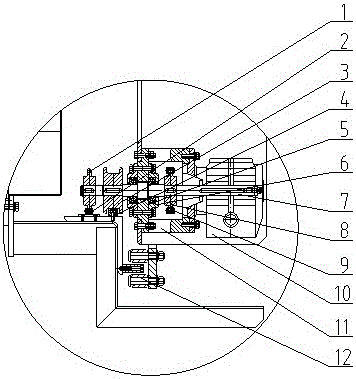

[0012] Embodiment 1: with reference to attached Figure 1-4 . A side beam filter cloth washing car chain traveling mechanism of a van filter press, including an active side helical worm gear reducer motor, an active and passive sprocket, a transmission shaft, a short-pitch roller chain, a sprocket mounting seat, and a water washing car support seat, bearing and bearing seat, travel limit wheel and support track, anti-skid sprocket chain and support track, water washing car anti-overturn limit hold wheel, chain tension adjustment device, passive side travel support wheel and track. The hollow shaft reduction motor 10 is fixed on the installation base 11 by bolts, the installation base 11 is fixed on the support frame of the washing car, the transmission shaft 7 is connected with the reduction motor 10 through the bearing 5, the bearing housing 6 and the key, and the driving sprocket 8 is connected through the chain 9 and driven sprocket 18 realize transmission connection, and ...

Embodiment 2

[0013] Example 2: On the basis of Example 1, a side-beam filter cloth washing car of a box-type filter press adopts a sprocket chain transmission mode and is installed in the washing support frame on the active side to drive the filter cloth car horizontally. Walking forward and backward; the transmission is separated from the traveling wheel, and the traveling wheel also has the function of lateral limit; the sprocket and chain mechanism are used to realize the anti-skid requirements on the track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com