Patents

Literature

43 results about "Diethylaluminium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

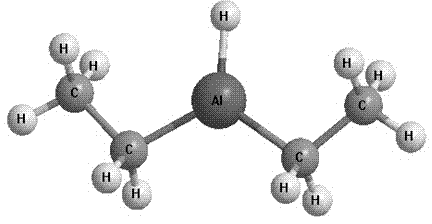

Diethylaluminium chloride is a highly hazardous organic compound and Lewis acid with the chemical formula C₄H₁₀AlCl. When dissolved in hexane, diethylaluminum chloride is a colorless liquid. It is used for polyolefin catalysis and as an intermediate in the preparation of organometallic compounds. It has a vapor density of 4.2 (air=1).

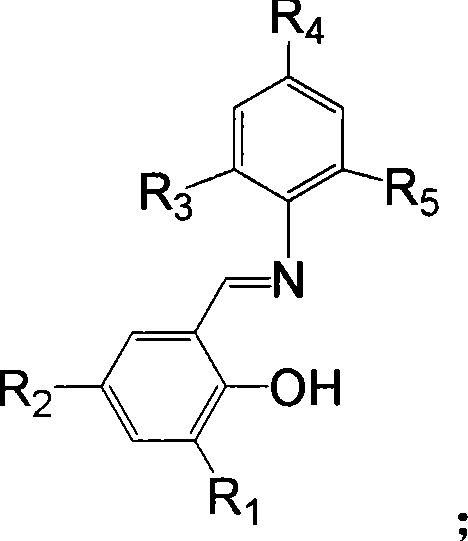

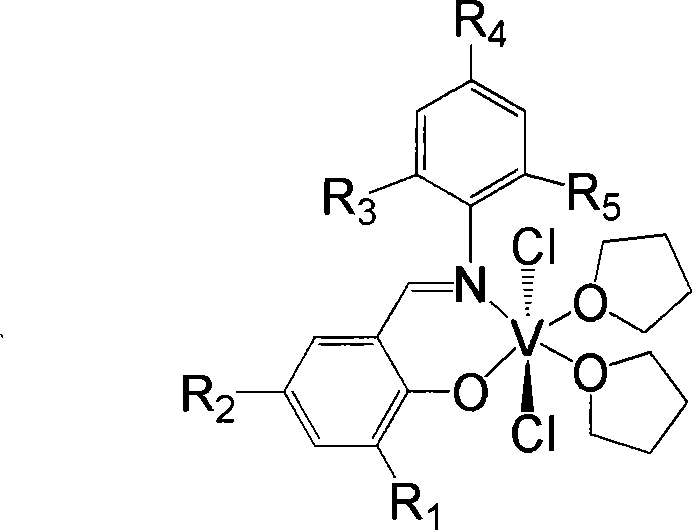

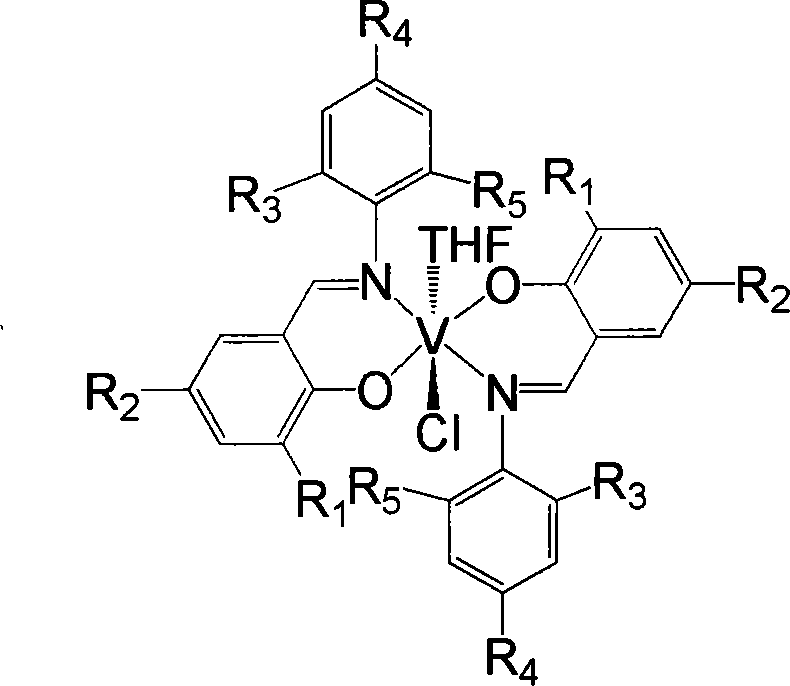

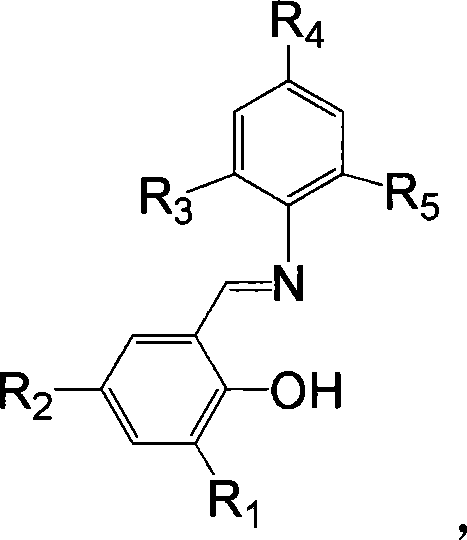

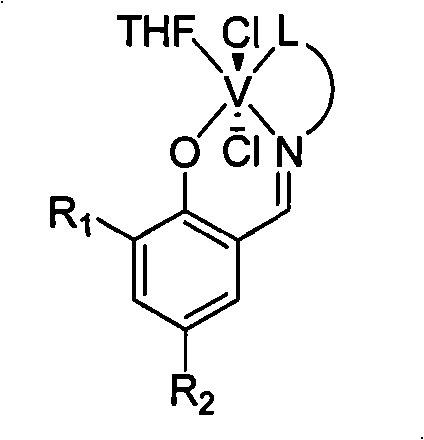

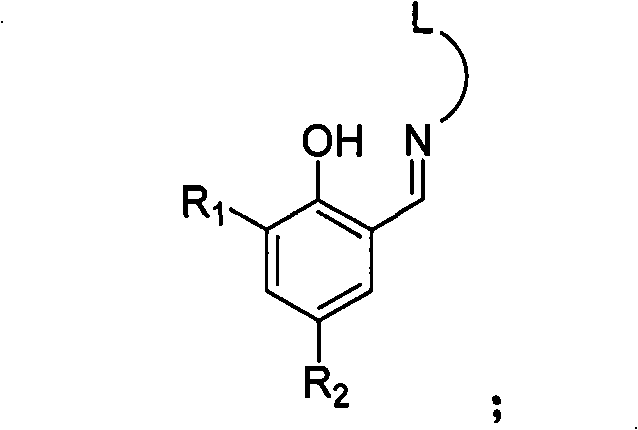

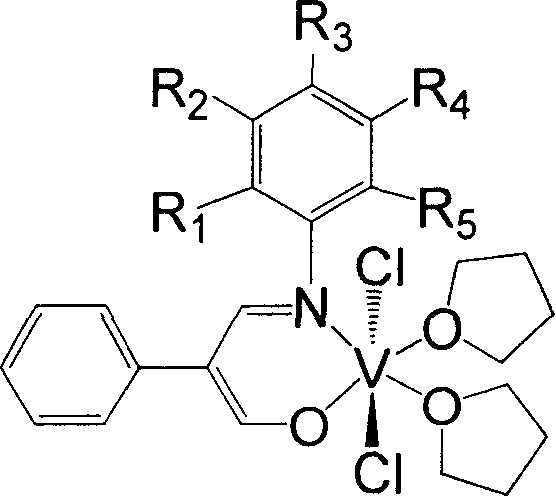

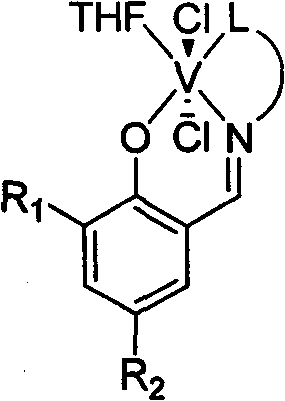

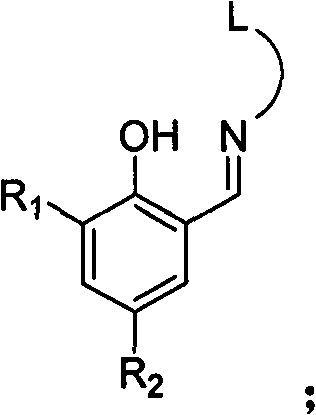

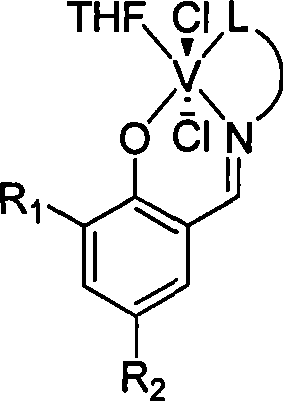

Single-salicylaldehyde imine vanadium olefin polymerization catalyst as well as preparation method and use thereof

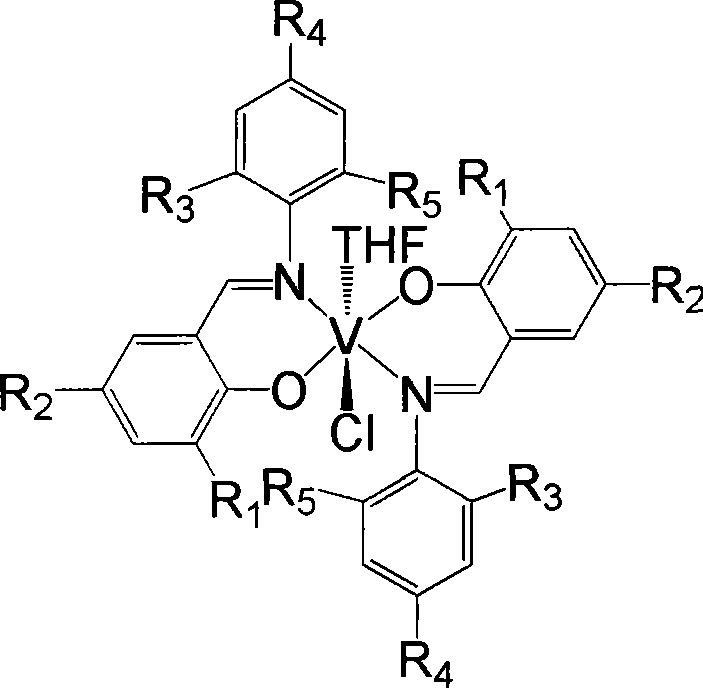

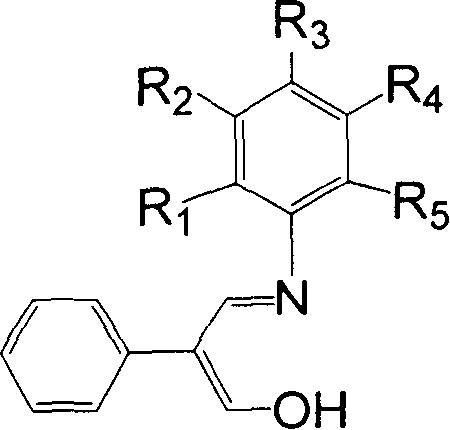

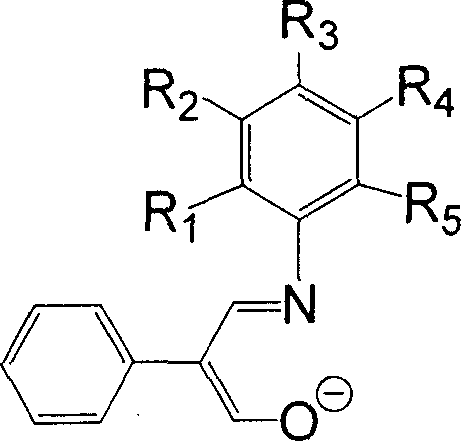

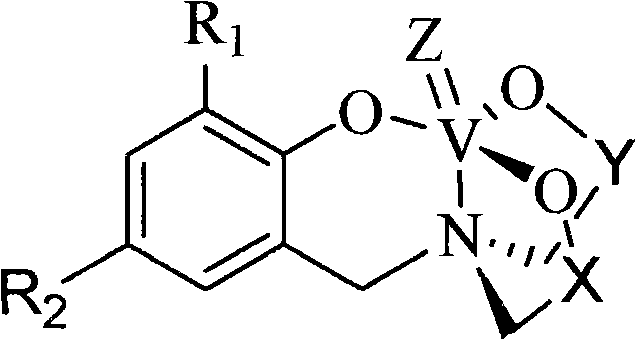

The invention relates to a method for preparing single salicylaldehyde imine vanadium olefin polymerization catalyst and application of the catalyst in catalyzing ethylene polymerization. Under the catalyzing effect of formic acid, condensation reaction of the salicylaldehyde or derivatives of the salicylaldehyde and aniline or derivatives of the aniline is carried out in methanol solution, and skiff base is obtained. Under the condition of no water and no oxygen and under the effect of excess triethylamine, the single salicylaldehyde imine vanadium olefin polymerization catalyst of the invention is obtained by complexation reaction of the skiff base and vanadium trichloride. Under the effect of diethyl aluminium chloride, the catalyst of the invention can be used for catalyzing ethylene polymerization. The invention has the advantages of easy preparation, high catalyzing activity and good thermal stability.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

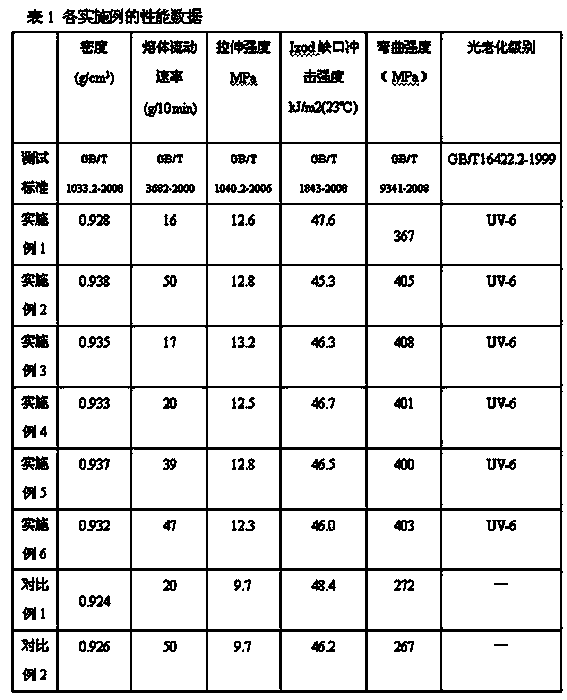

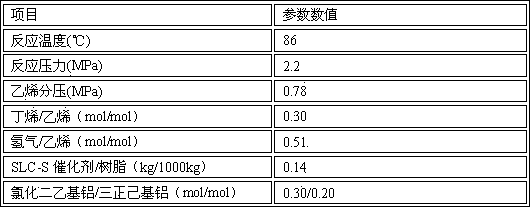

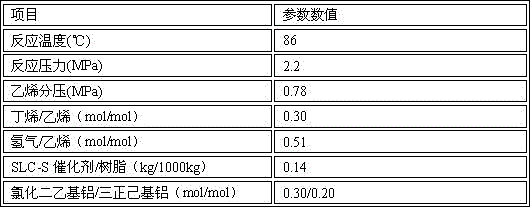

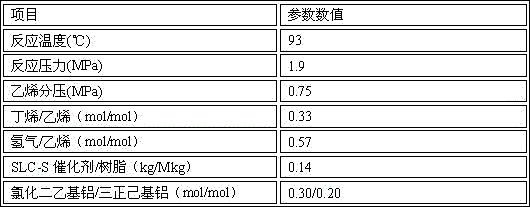

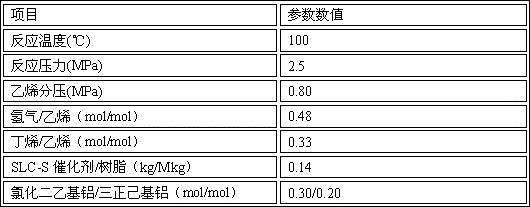

High-rigid linear low-density polyethylene injection moulding resin

ActiveCN104292595ASolve rigid problemsSolve weather resistanceLow-density polyethyleneLinear low-density polyethylene

The invention relates to a high-rigid linear low-density polyethylene injection moulding resin which is prepared from following substances including, by weight, 100 parts of linear low-density polyethylene, 0.15-0.3 parts of a photo-stabilizing agent, 0.05-0.15 parts of an anti-oxygen agent, 0.02-0.10 parts of a halogen absorbing agent, and 0.05-0.10 parts of a rheology modifier. The linear low-density polyethylene is prepared from a following method comprising a step of polymerization through a Unipol gas-phase technology with ethylene as a raw material, 1-butylene as a co-polymer monomer, hydrogen as a chain transfer agent, SLC-S as a catalyst and diethylaluminium chloride and tri-n-hexylaluminium as co-catalysts. The high-rigid linear low-density polyethylene injection moulding resin is good in resin uniformity, rigid-flexible balanced performance and processability, has an excellent anti-ultraviolet light aging property and is mainly used in injection moulding of outdoor products.

Owner:CHINA PETROLEUM & CHEM CORP +1

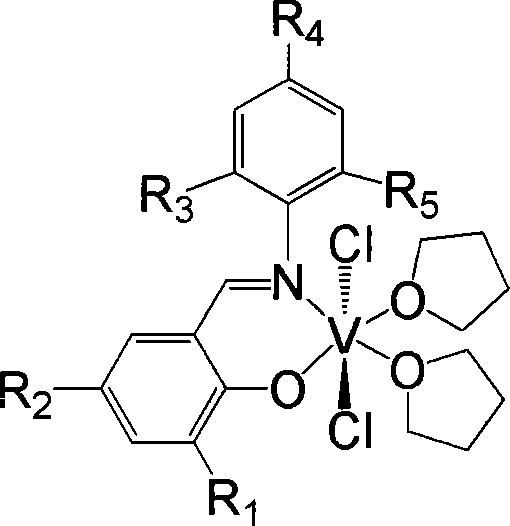

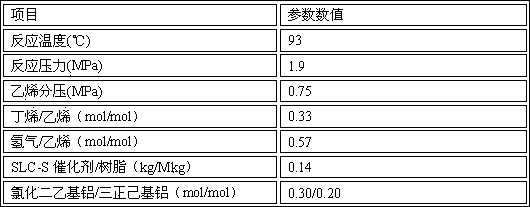

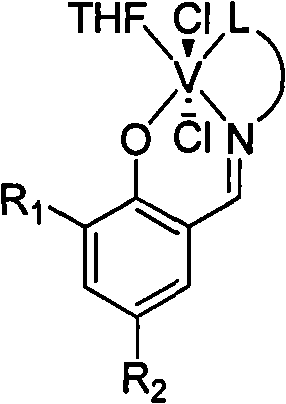

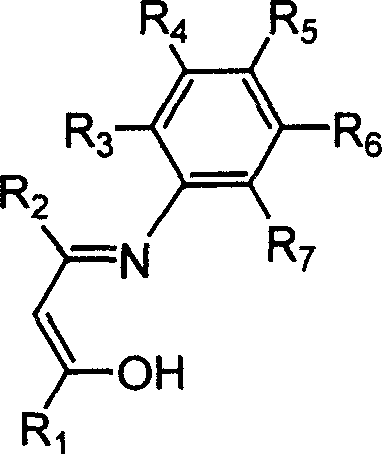

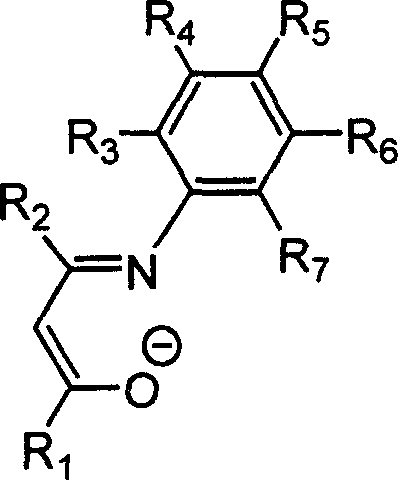

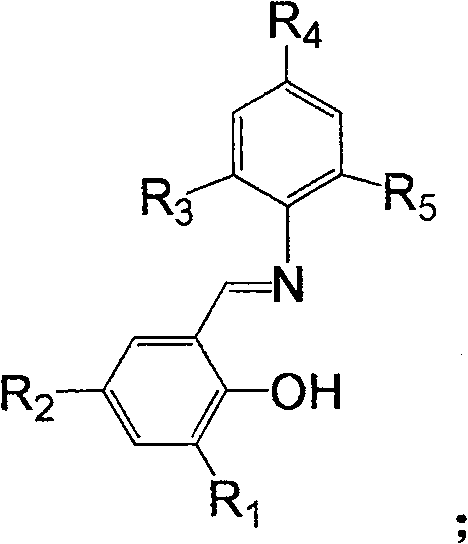

Bis-salicylaldehyde imine vanadium olefin polymerization catalyst as well as preparation method and use thereof

The invention relates to a method for preparing double salicylaldehyde imine vanadium olefin polymerization catalyst and application of the catalyst in catalyzing ethylene polymerization. Under the catalyzing effect of formic acid, condensation reaction of the salicylaldehyde or derivatives of the salicylaldehyde and aniline or derivatives of the aniline is carried out in methanol solution, and skiff base is obtained. Under the condition of no water and no oxygen and under the effect of excess triethylamine, the double salicylaldehyde imine vanadium olefin polymerization catalyst of the invention is obtained by complexation reaction of the skiff base and vanadium trichloride with an equivalent weight. Under the effect of diethyl aluminium chloride, the catalyst of the invention can be used for catalyzing ethylene polymerization. The invention has the advantages of easy preparation, high catalyzing activity and good thermal stability.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

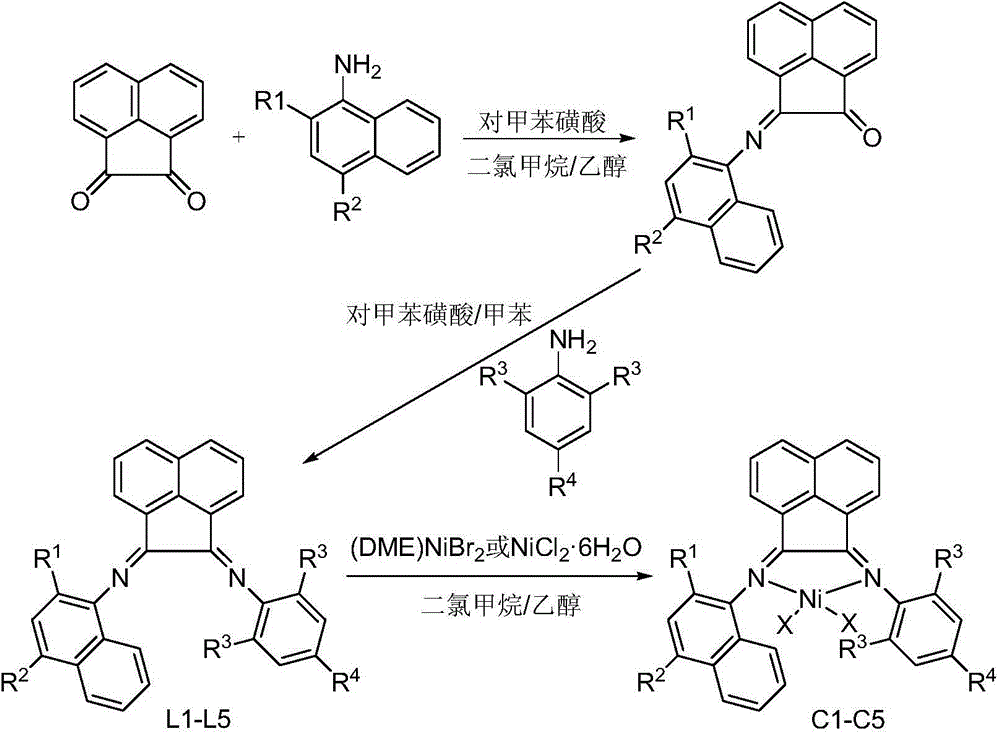

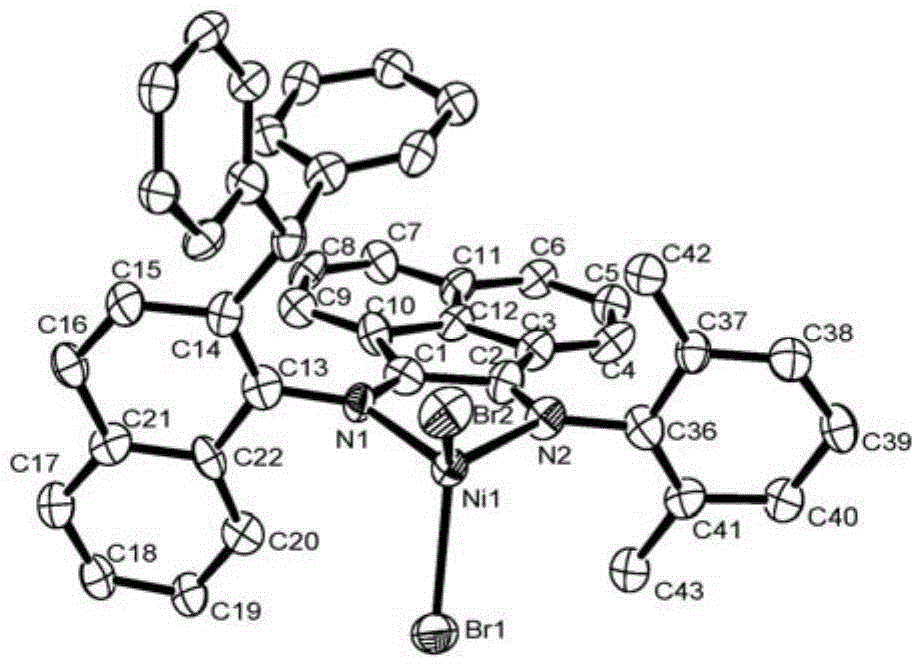

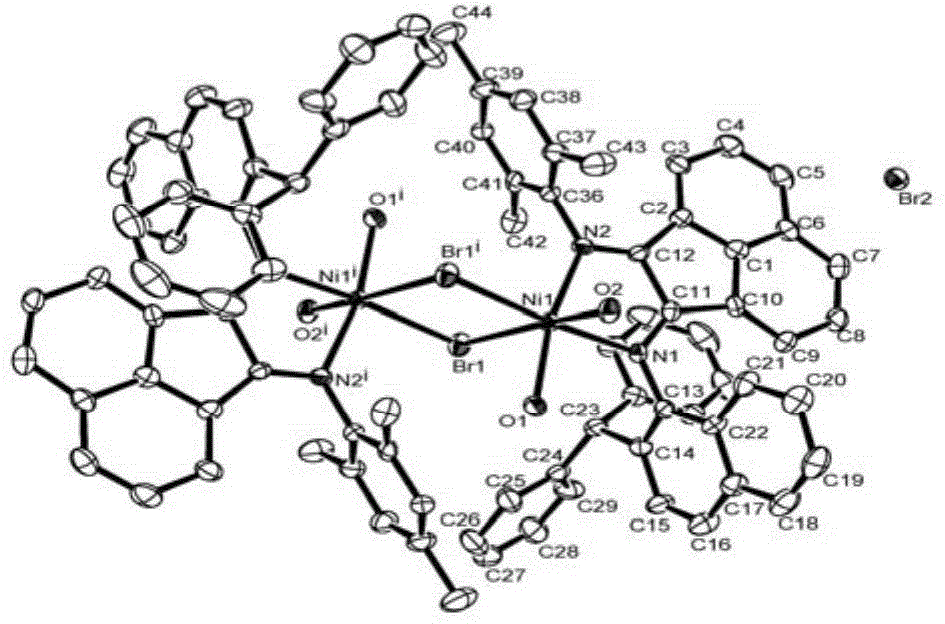

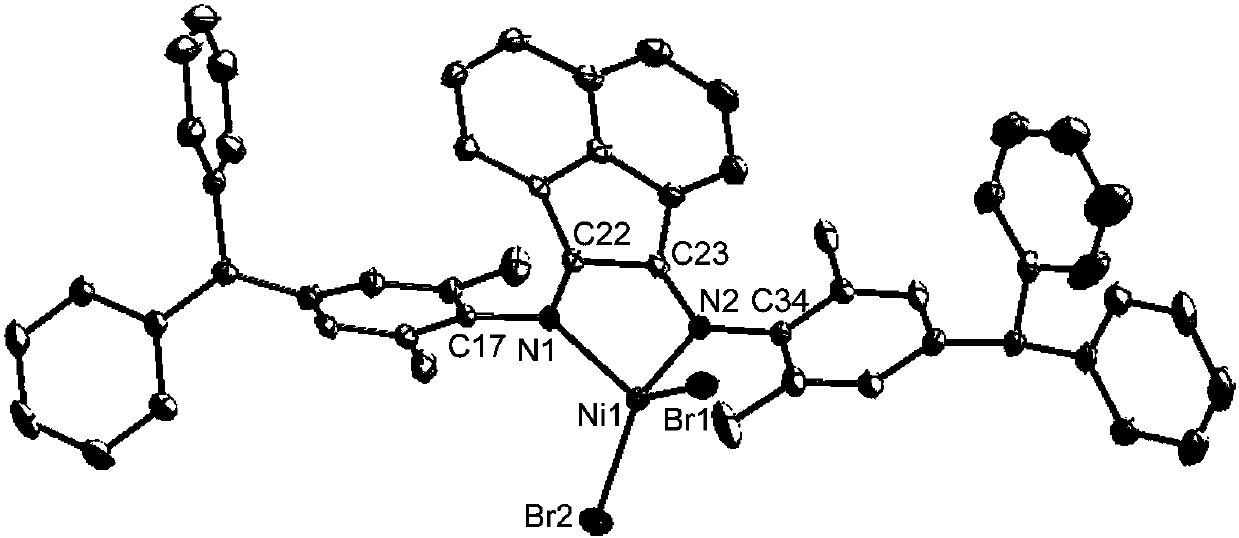

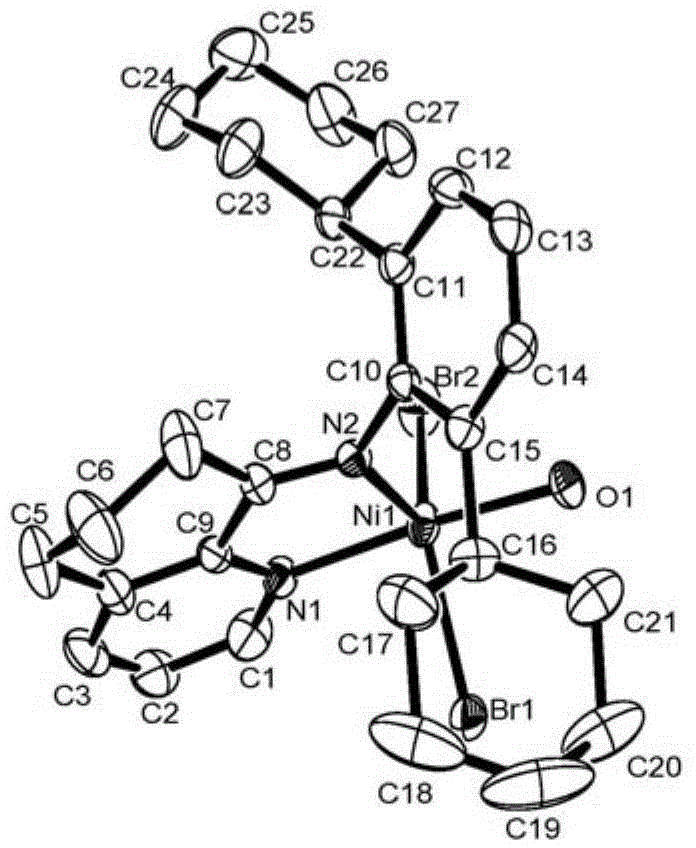

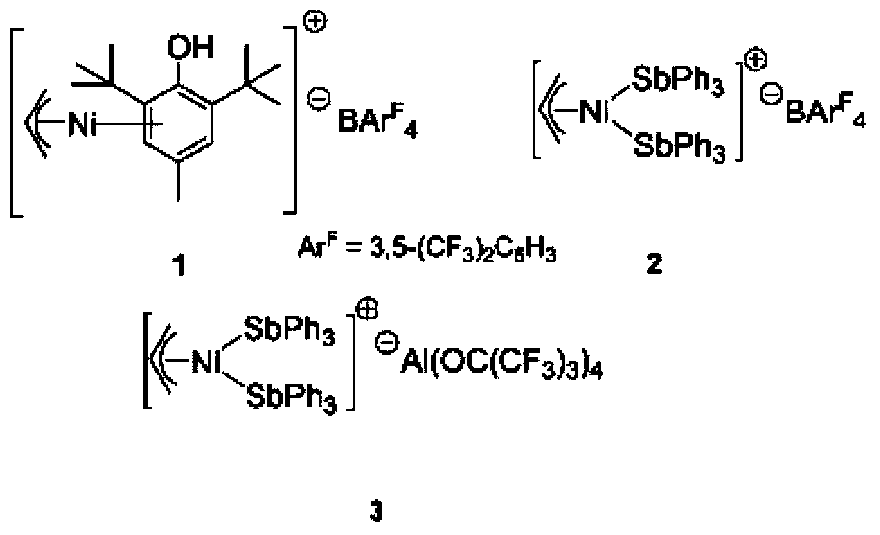

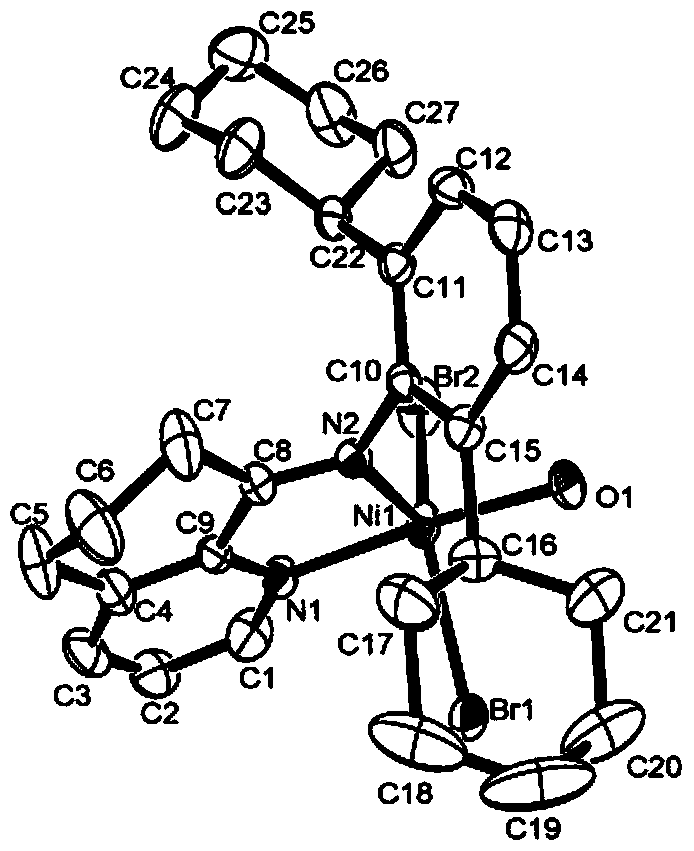

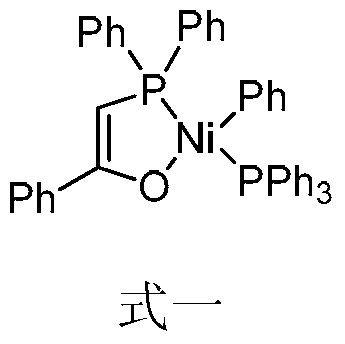

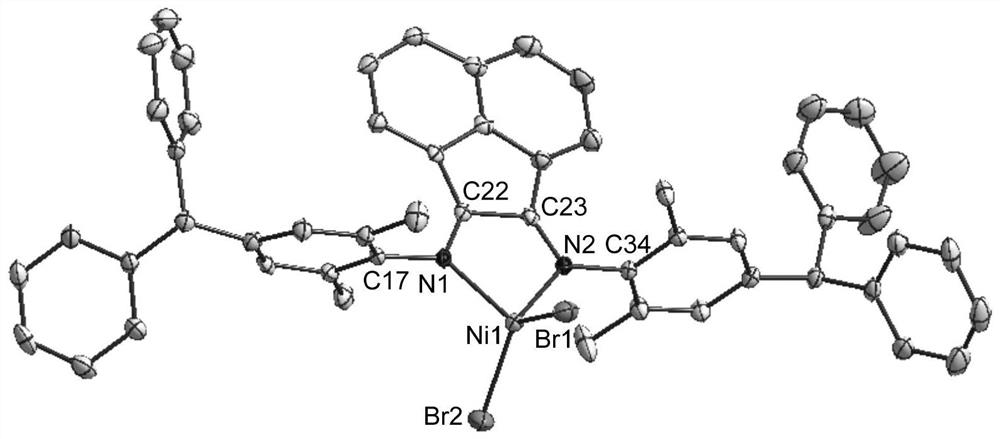

Naphthyl-substituted asymmetric acenaphthenediimine nickel complexes, and preparing method and applications thereof

ActiveCN105646598ASimple preparation processConfirmed crystal structureNickel organic compoundsImino compound preparationOxygenPhenyl group

The invention relates to a catalyst containing naphthyl-substituted asymmetric acenaphthenediimine nickel complexes, a preparing method of the complexes and applications of the complexes. The general structure of the nickel complexes is shown as a formula I, wherein R<1> is bis(phenyl)methyl or bis(fluorophenyl)methyl, R<2> is hydrogen and bis(phenyl)methyl or bis(fluorophenyl)methyl, R<3> is C1-C3 alkyl, R<4> is hydrogen or methyl, and X is selected from bromine or chlorine. The preparing method includes reacting ligands shown as a formula V and (DME)NiBr2 or NiCl2.6H2O under oxygen-free conditions to obtain the nickel complexes shown as the formula I. Under the existence of a cocatalyst that is diethylaluminium chloride or / and methylaluminoxane, and the like, the nickel complexes can catalyze ethylene polymerization well to obtain polymer with a high molecular weight and a low degree of branching. The highest catalyzing activity of the nickel complexes can be 7.71*10<6> g.mol<-1>(Ni).h<-1>. The nickel complexes have a wide industrial application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

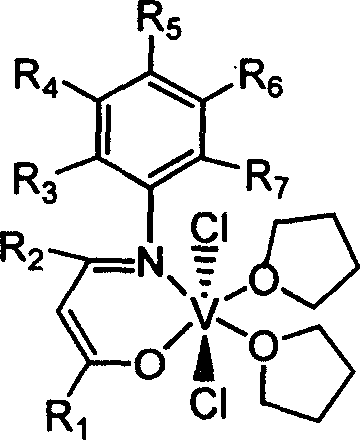

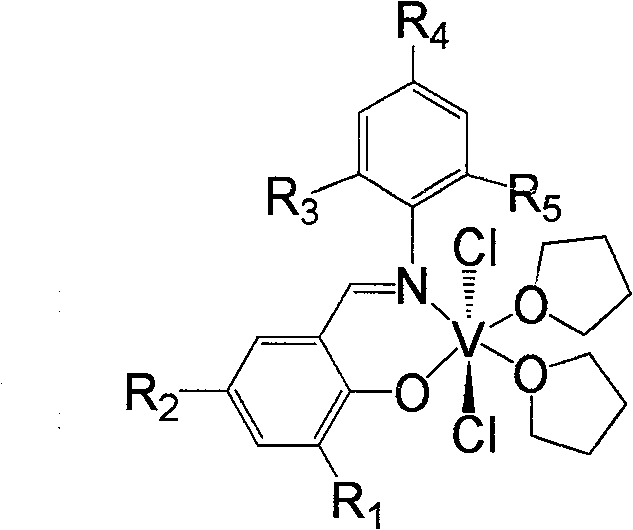

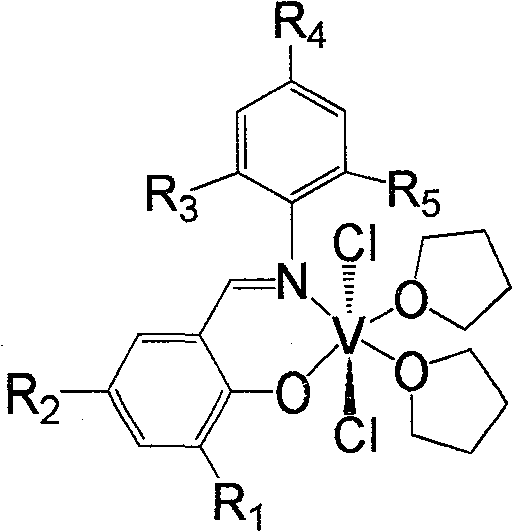

Three-tooth salicylaldehyde imine vanadium olefin polymerizing catalyst, preparation and uses thereof

The invention relates to a polymerization catalyst of tridentate salicylaldehyde imine vanadium alkene, a preparation method thereof and an application thereof. By the catalysis of formic acid, condensation reaction is carried out between the derivatives salicylaldehyde or salicylaldehyde, and amine compounds in methanol solution to obtain Schiff base; under the condition of no water and no oxygen, the Schiff base strips hydrogen protons and complexation reaction is carried out with vanadium trichloride to obtain the polymerization catalyst of tridentate salicylaldehyde imine vanadium alkene; by the action of aluminium diethyl monochloride, the polymerization catalyst is applied to catalyzing ethylene for polymerization; and by the action of aluminium diethyl monochloride, the polymerization catalyst is applied to the copolymerization of ethylene and 1-hexylene at 25 DEG C and used for catalyzing the copolymerization of ethylene and norbornene at the temperature of 50 DEG C. The polymerization catalyst has the advantages of convenient preparation, high catalytic activity, good heat stability, strong copolymerization capacity, etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

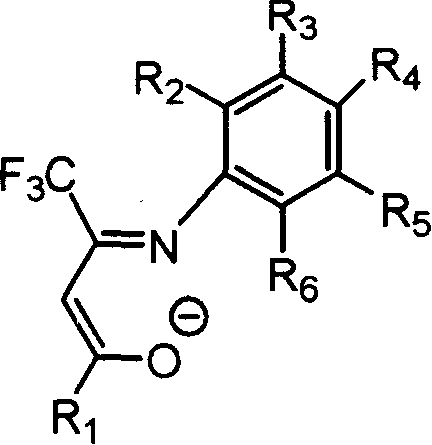

Beta-diketo mono imine vanadium olefinic polymerization catalyst, and its preparing method and use

The invention discloses a beta-diketone mono-imide vanadium olefinic polymerization catalyst and the manufacture method and the application of ethylene polymerizing, ethylene and norborene polymerizing, ethylene and alpha-alkene or norborene copolymerization. Under the catalysis of formic acid, beta-diketone compound and aniline or the ramification of aniline taking condensation reaction in methanol solution to gain Schiff base; under the non water and non oxygen condition, the Schiff base taking reaction with butyl lithium to gain negative ion ligand; under the non-water, non oxygen condition, the negative ion ligand taking coordination reaction with VCl3, the beta-ketimine vanadium alkene polymerization catalyst could be gained. The invention could catalyze ethylene polymerization, and the copolymerizing of ethylene and alpha-alkene or norborene.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

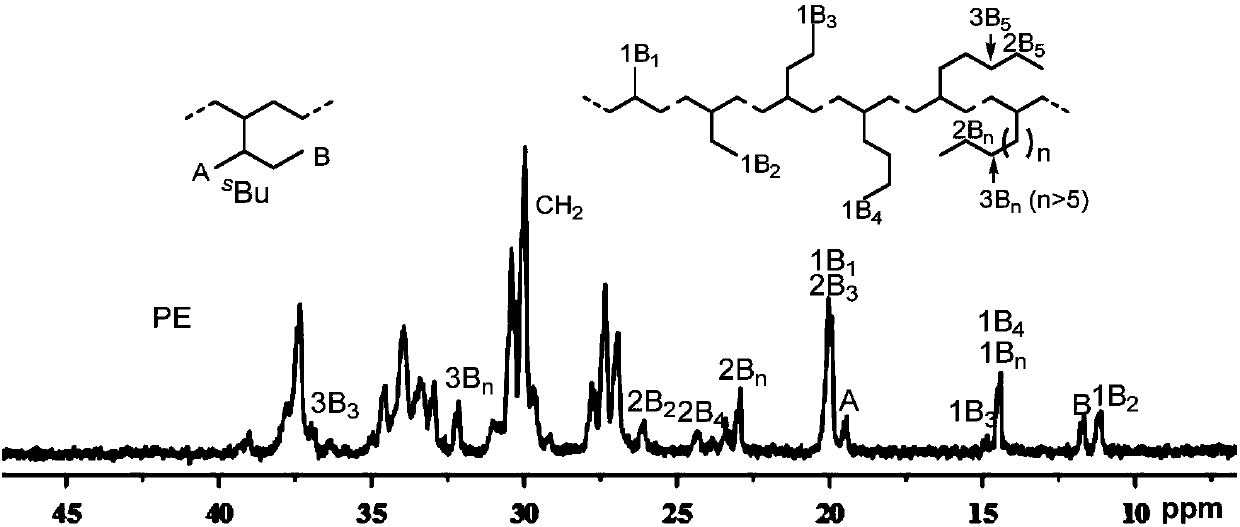

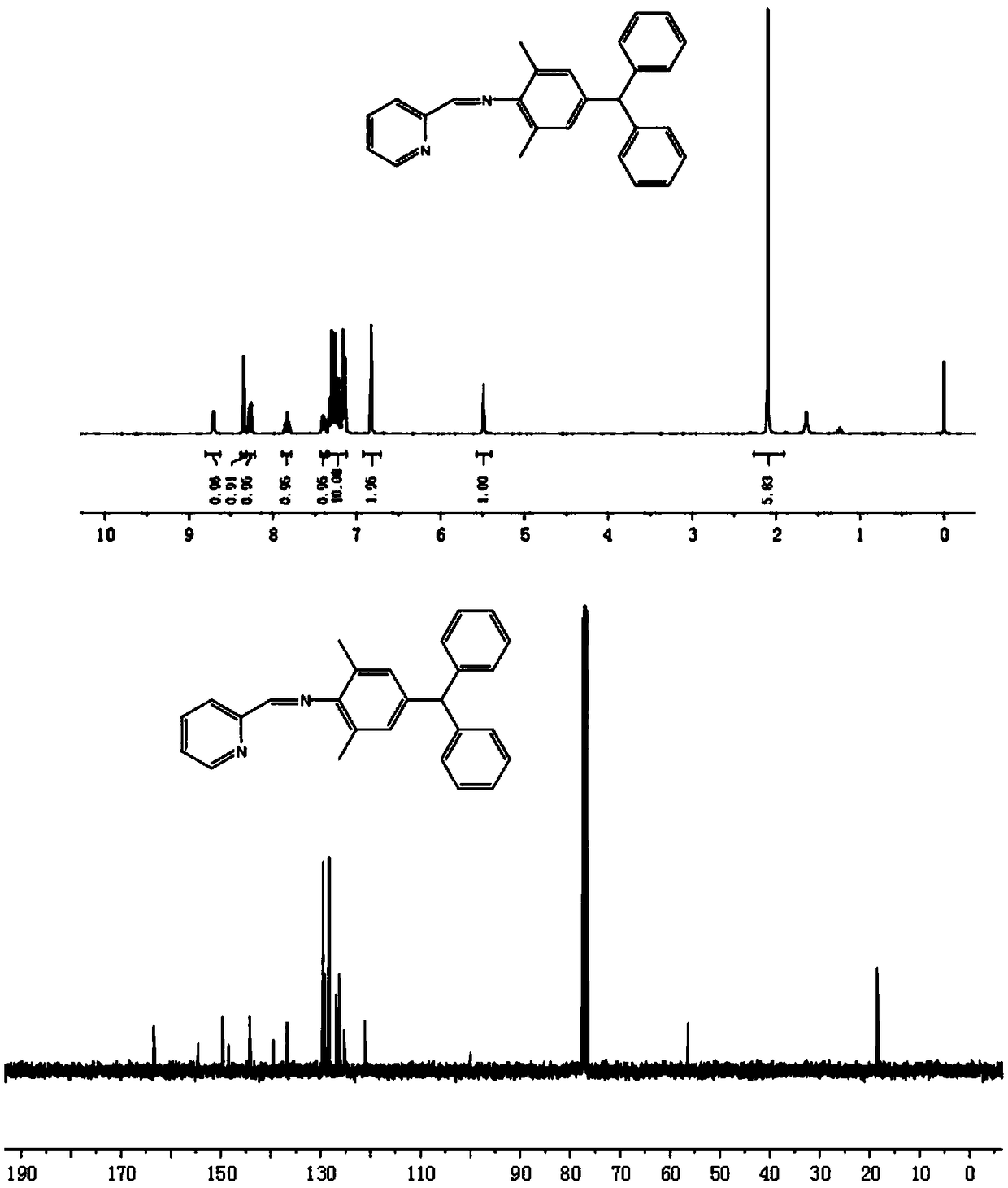

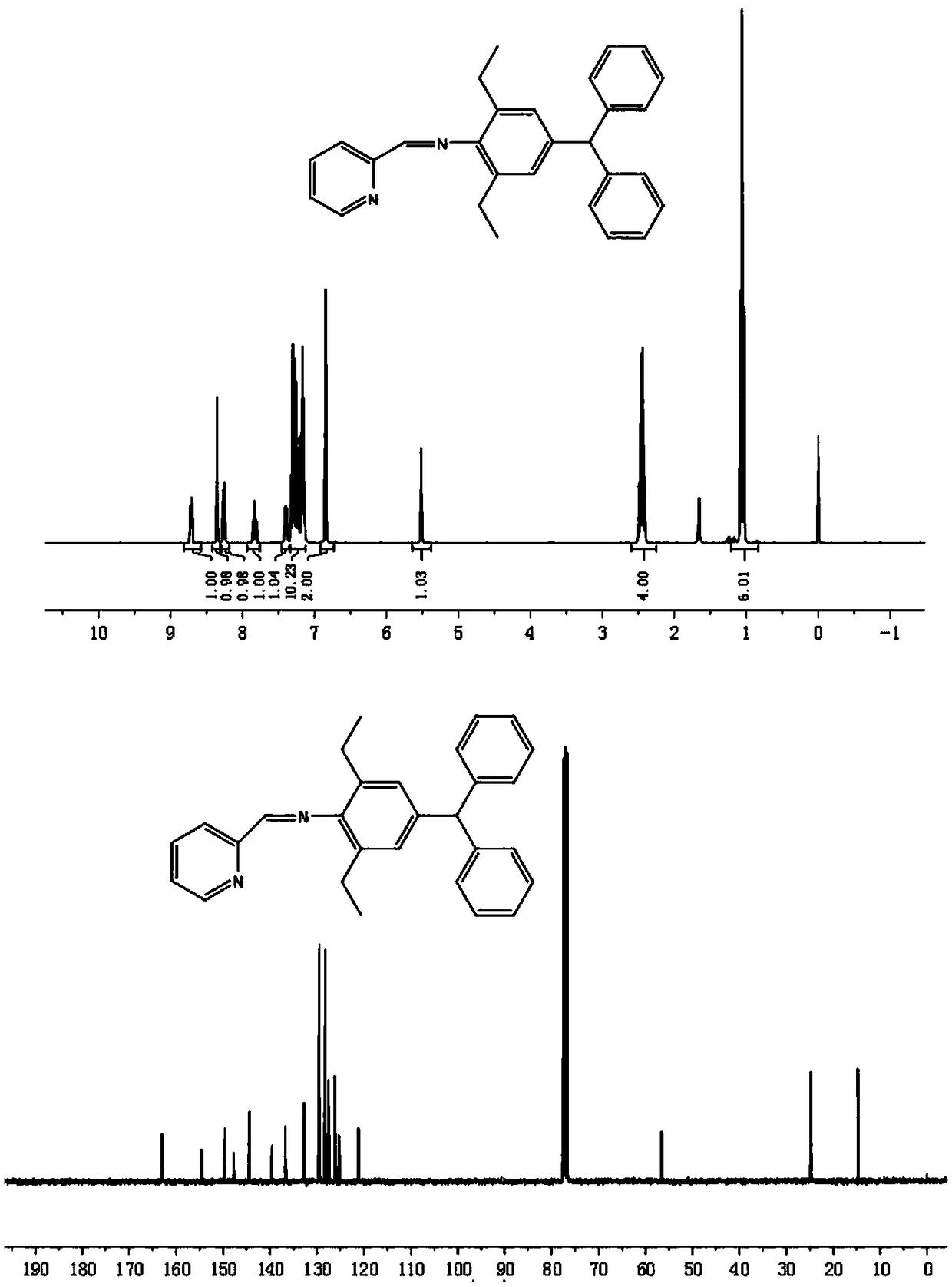

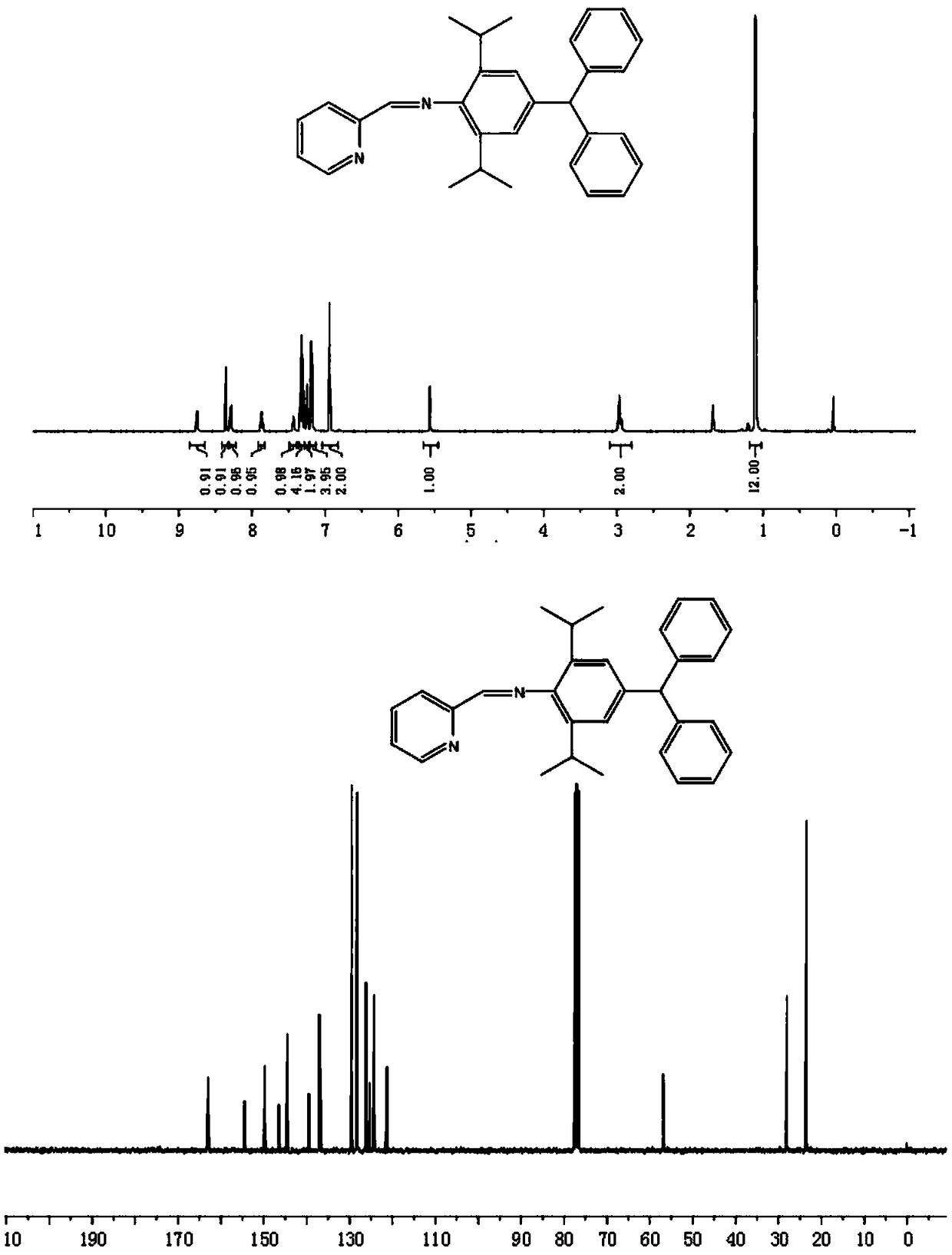

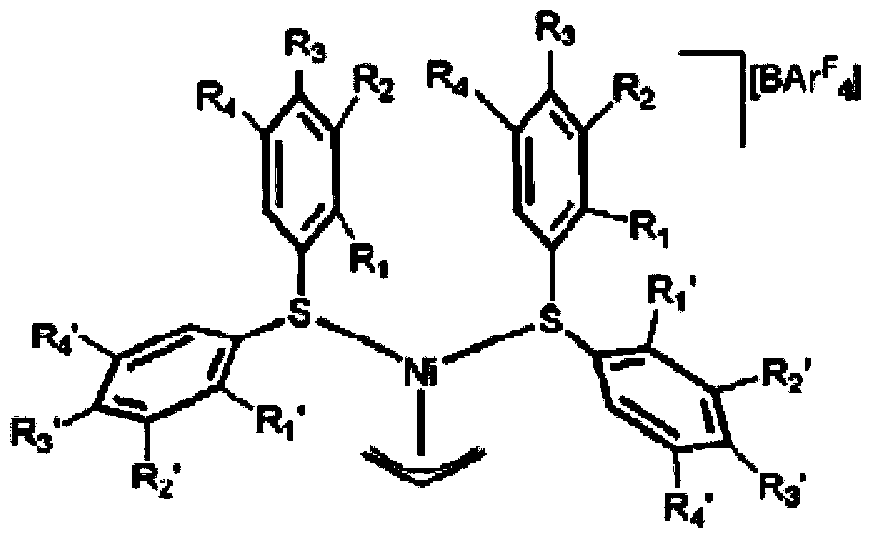

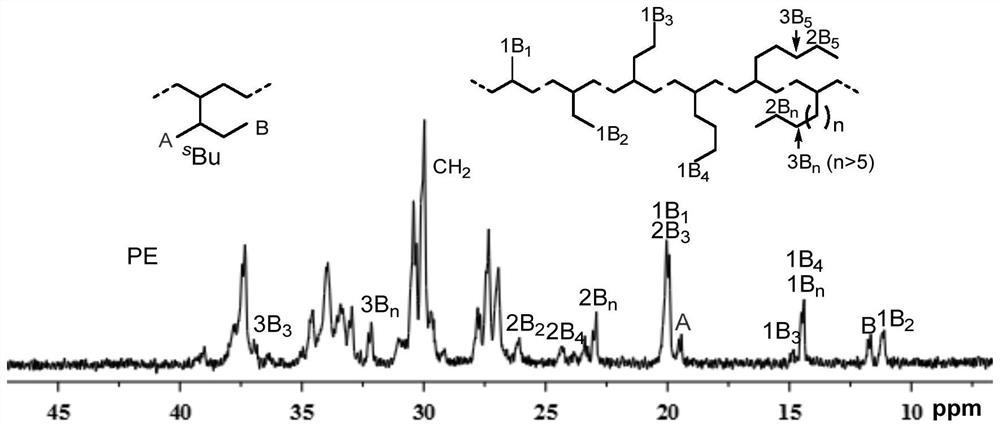

Alpha-diimine nickel (II) complexes containing p-benzhydryl substitutes and used for catalyzing polymerization of ethylene and 2-hexene

ActiveCN107698699AIncrease the degree of branchingDensity protectionNickel organic compoundsPolymer sciencePolyolefin

Novel late-transition-metal alpha-diimine nickel (II) complexes containing p-benzhydryl substitutes are disclosed. According to the complexes, two bulky groups which are benzhydryl are introduced to the para positions of imine nitrogen atoms on aromatic rings, and therefore ethylene insertion is accelerated, catalyst activity is improved, the transferring rate of active chains to a monomer is reduced, and a polymer having a high molecular weight is prepared. Under activation by a cocatalyst that is diethylaluminium chloride, a catalytic system catalyzing ethylene polymerization has high catalytic activity (can be 10<6> g PE / (mol Ni h)), and prepared polyethylene having a high molecular weight has a high degree of branching (can be 131 branches per 1000 C). Because of ortho-position small-steric-hindrance substitution and immobilization by para-position bulky benzhydryl, 2-hexene can be easily inserted to a metal center, and therefore chain shuttling polymerization of the 2-hexene has ahigh conversion ratio (88%), and a branch polymer having a high molecular weight and a low degree of dispersion is obtained. Accordingly, the catalyst has good potential application value in industrial polyolefin production.

Owner:CHANGZHOU UNIV

Process for preparing 4-acyl substituted-2-methylpiperazines

ActiveCN1827610AEliminate potential safety hazardsRaw materials are cheap and easy to getOrganic chemistryAluminium chlorideCarboxylic acid

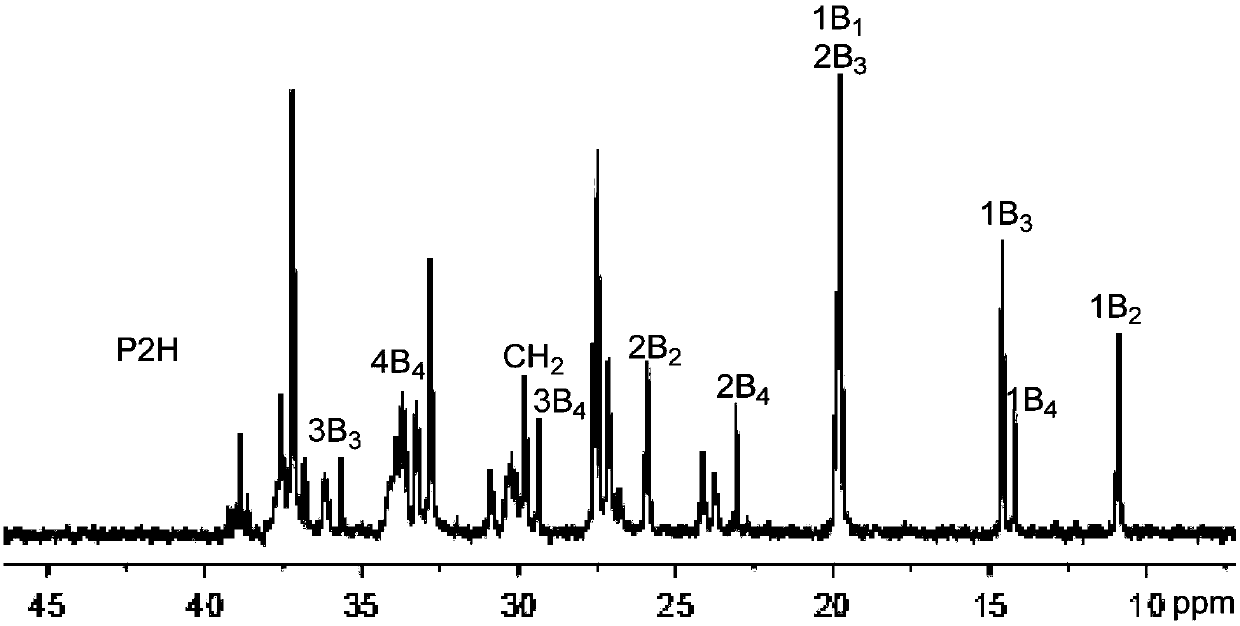

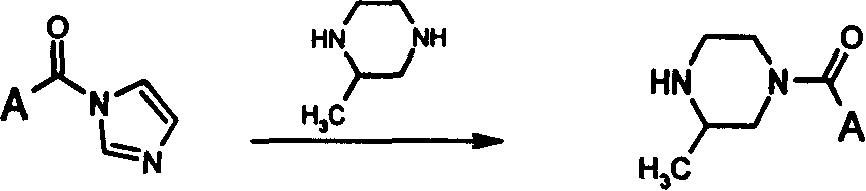

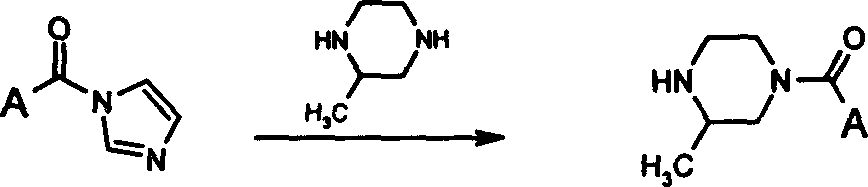

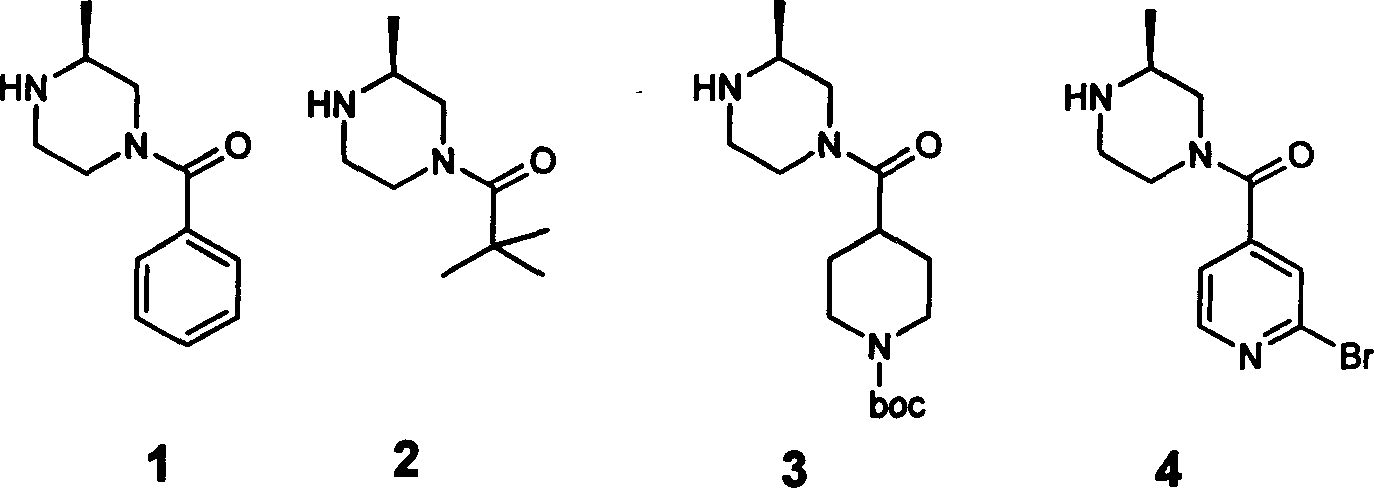

The invention relates to a method for preparation of selective monoacylated piperazine by N,Ní»-carbonyldiimidazole(CDI) activating carboxyl acid and especially to a method for preparation of 4-acylsubstitution-2-methylpiperazine compound by selectively monoacylating 4-nitrogen atom of 2-methylpiperazine ring.It is characterized in that it prepares carbonyl diimidazolederivant by the reaction of between N,Ní»-carbonyldiimidazole and carboxyl acid, and monoacylated 4-acylsubstitution-2-methylpiperazine compound is obtained by monoacylated condensation reaction between 2-methylpiperazine and the substances of the former step. In relation to the present technology, the said invention selects N,Ní»-carbonyldiimidazole which is cheap and easy for commercial manufacture as effective substitute agent of diethyl aluminium chloride, essentially removes potential safety hazard, avoids the explosive diethyl aluminium chloride, and is of simple operation and high reaction yield rate.

Owner:深圳市天明医药科技开发有限公司

Polymerizing process for improving flowability of copolypropylene powder

A polymerizing process for improving the flowability of copolypropylene powder features that the Z-N type Ti-series polypropylene catalyst system is used in the multi-phase block polymerization of polypropylene, the superfine inorganic material, said catalyst system, the trialkyl aluminium (triethyl aluminium or aluminium diethylchloride) as co-catalyst, and the alkoxyl silane as electron provider are used, and the mechanical stirring is combined with ultrasonic for uniformly dispersing said inorganic material chosen from saperfine talc powder and superfine calcium carbonate.

Owner:SINOPEC YANGZI PETROCHEM

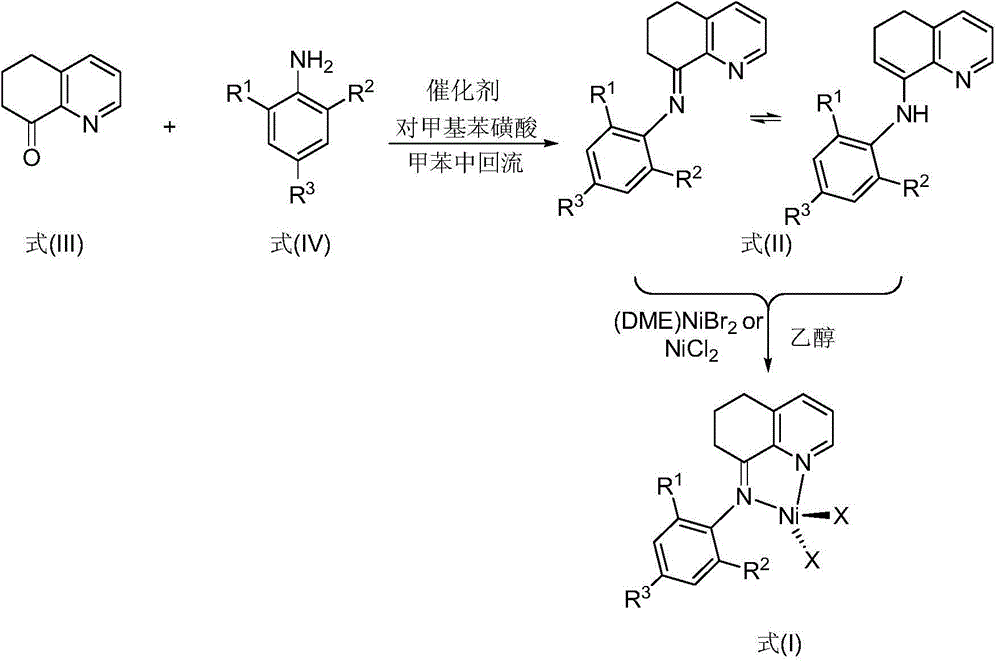

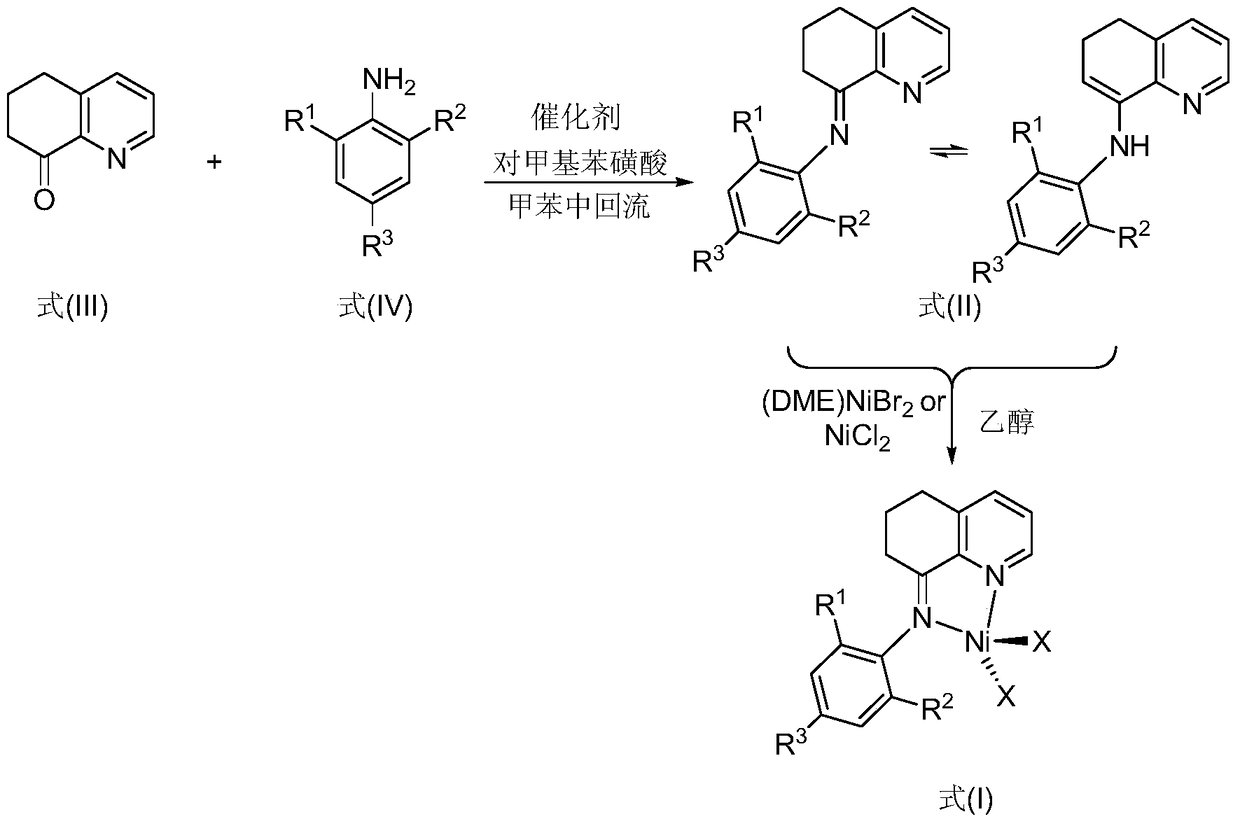

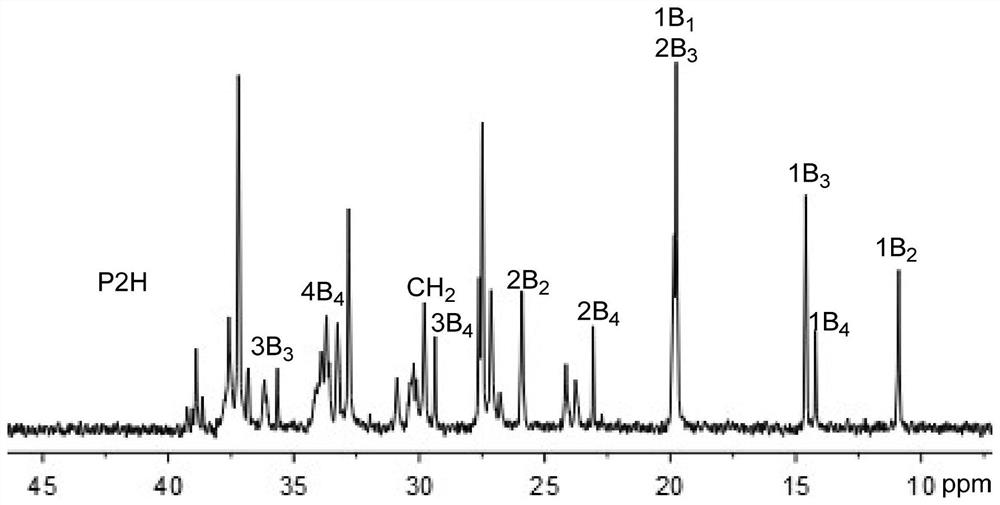

N-5,6,7-hydro-quinoline-8-aryl imine nickel complex catalyst and preparation method and application thereof

ActiveCN105646597AGreat potential for industrial applicationsIncrease the degree of branchingNickel organic compoundsArylQuinoline

The present invention relates to a cycloalkyl-substituted N-5,6,7-hydro-quinoline-8-aryl imine nickel complex catalyst and a preparation method and application thereof. The N-5,6,7-hydro-quinoline-8-aryl imine nickel complex catalyst has a structural general formula as shown in a formula I. The catalyst complex can well catalyze vinyl polymerization under the effect of cocatalyst methylaluminoxane, diethylaluminium chloride and the like to obtain a low molecular weight high branching degree polymer, the catalyst complex also has high activity, the highest activity is up to 5.33*106g (PE) mol (Ni) <-1>h<-1>; the molecular weight of obtained polyethylene wax is 1430-3330g / mol, the molecular weight distribution is between 1.38-1.92, the branching degree is up to 422 / 1000C, and the catalyst complex has good prospects for industrial application.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Beta-hydroxy propyleneimine vanadium olefinic polymerization catalyst and its preparation method and uses

This invention relates to a beta-hydroxy-propyleneimine-vanadium-alkene polymerization catalyst, method for making same, and the application of this catalyst in catalyzing ethylene polymerization, ethylene and norbornene polymerization, ethylene and alpha-alkene polymerization. Under the catalysis of formic acid, 2-phenyl-3-hydroxy-propenal performs condensation reaction with phenylamine or phenylamine derivant in methanol solution to produce Schiff's base; under the anhydrous and anaerobic condition, the above Schiff's base reacts with n-butyl-lithium to produce negative ion ligand; under the anhydrous and anaerobic condition, the negative ion ligand reacts with the coordinate position of vanadium trichloride to produce this invented beta-hydroxy-propyleneimine-vanadium-alkene polymerization catalyst. Under the action of diethyl-aluminium chloride, this invented catalyst can catalyze ethylene polymerization, ethylene and norbornene or alpha-alkene polymerization.This invention is characterized of convenient producing, high catalyzing activity, good thermal stability and strong polymerization.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

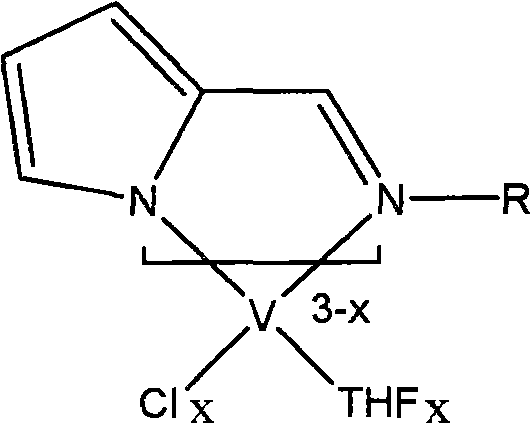

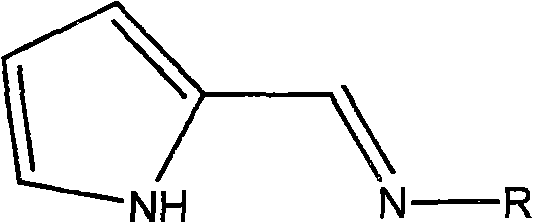

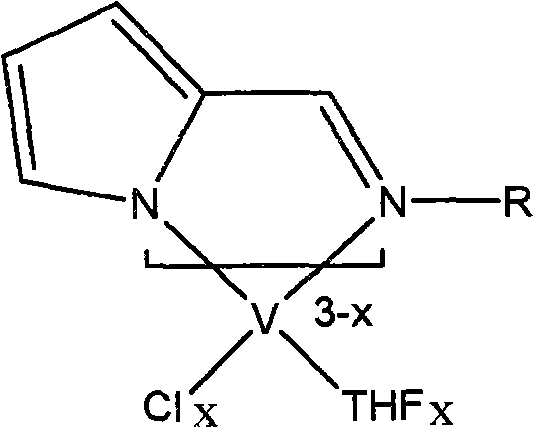

Pyrrole imine vanadium olefin polymerization catalyst, preparation method and applications thereof

The invention relates to a pyrrole imine vanadium olefin polymerization catalyst, a preparation method and applications of the catalyst in the catalization of ethylene polymerization, copolymerization of ethylene and undecylenic alcohol, copolymerization of ethylene and olefin butyl alcohol and copolymerization of ethylene and methyl undecylenate. The condensation reaction is carried out on 2-formylpyrrole and amine compounds in methanol solution under the catalysis of methanoic acid to obtain Schiff base; the deprotonation of hydrogen is carried out on the Schiff base, then the coordination reaction is carried out on the Schiff base and vanadium trichloride under anhydrous and oxygen-free condition, so as to obtain the pyrrole imine vanadium olefin polymerization catalyst. The catalyst can catalyze the ethylene polymerization, the copolymerization of ethylene and undecylenic alcohol, the copolymerization of ethylene and olefin butyl alcohol and the copolymerization of ethylene and methyl undecylenate under the action of diethylaluminum chloride. The catalyst has the advantages of convenient preparation, high catalytic activity, good thermal stability, strong copolymerization ability and the like.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Method for preparing palladium pyridine imine (II) catalyst and preparing oil-phase oligomer by catalyzing ethylene

InactiveCN108822237AIncrease the degree of branchingHigh catalytic activityOrganic chemistry methodsGroup 8/9/10/18 element organic compoundsPolyolefinOil phase

The invention discloses a series of novel complexes containing para-diphenylmethyl substituted late transition metal palladium pyridine imine (II). According to the complexes, a large-volume group ofbenzhydryl is introduced at a para-position of an imine nitrogen atom aromatic ring, so that the ethylene insertion process is accelerated, and the activity of a catalyst is improved; such pyridiniumligand has a higher transfer rate from an active chain to a monomer and a low molecular weight oil polymer is obtained. Under the activation of a promoter diethylaluminium chloride, the catalytic system has higher catalytic activity (which can reach 3.86*10<5>g PE / (mol.Pd.h)) in the aspect of catalyzing ethylene polymerization, and the obtained amorphous oil polyethylene has a higher branching degree (which can reach 130 branches per 1,000 C). Therefore, such catalyst has high application value in the production of polyolefin oil.

Owner:CHANGZHOU UNIV

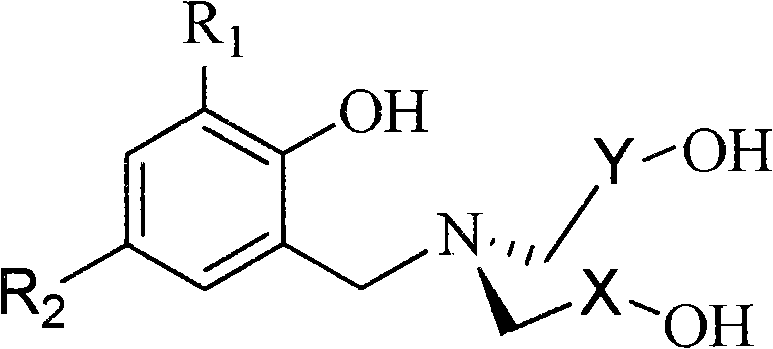

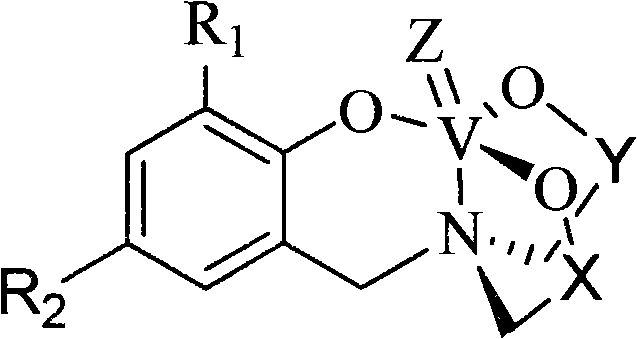

Polyhydroxy pentavalent vanadium olefin polymerization catalyst, preparation method and application

The invention relates to a polyhydroxy pentavalent vanadium olefin polymerization catalyst, a preparation method and application. Under the anhydrous oxygen-free conditions, complexation reaction occurs between polyhydroxy ligand or ligand anion with proton removed and equal amount of VO(OPr)3 or VCl3(N-2,6-Me2C6H3), thus obtaining the polyhydroxy pentavalent vanadium olefin polymerization catalyst. Under the action of aluminium diethyl monochloride, the catalyst catalyzes ethylene for polymerization, ethylene and hexylene for copolymerization, ethylene and norbornene for copolymerization, ethylene and 5-norbornene-2-methanol for copolymerization, thus obtaining a polymer with high molecular weight and high comonomer insertion rate. The polymerization catalyst has the advantages of convenient preparation, high catalytic activity, good thermal stability, strong polar monomer resistance, and the like.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

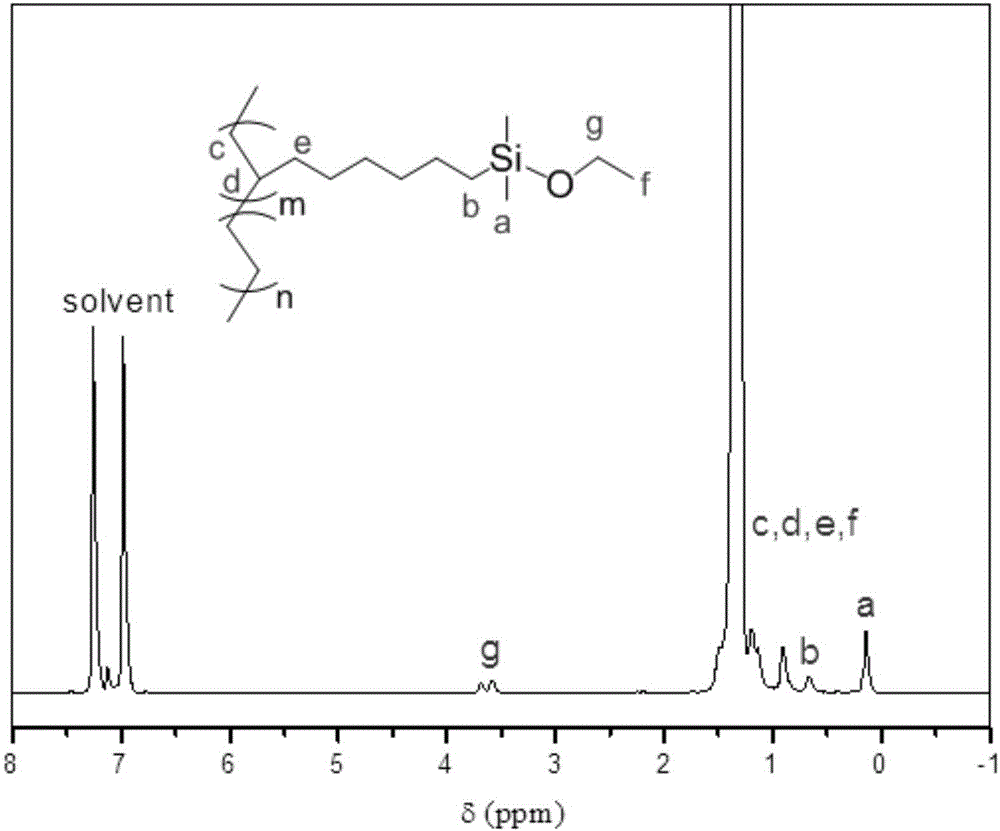

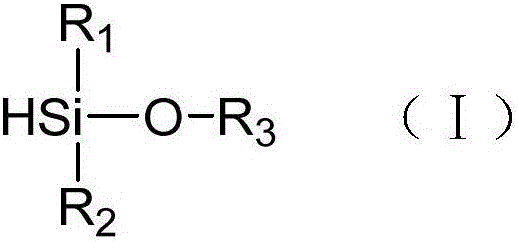

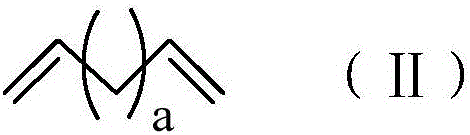

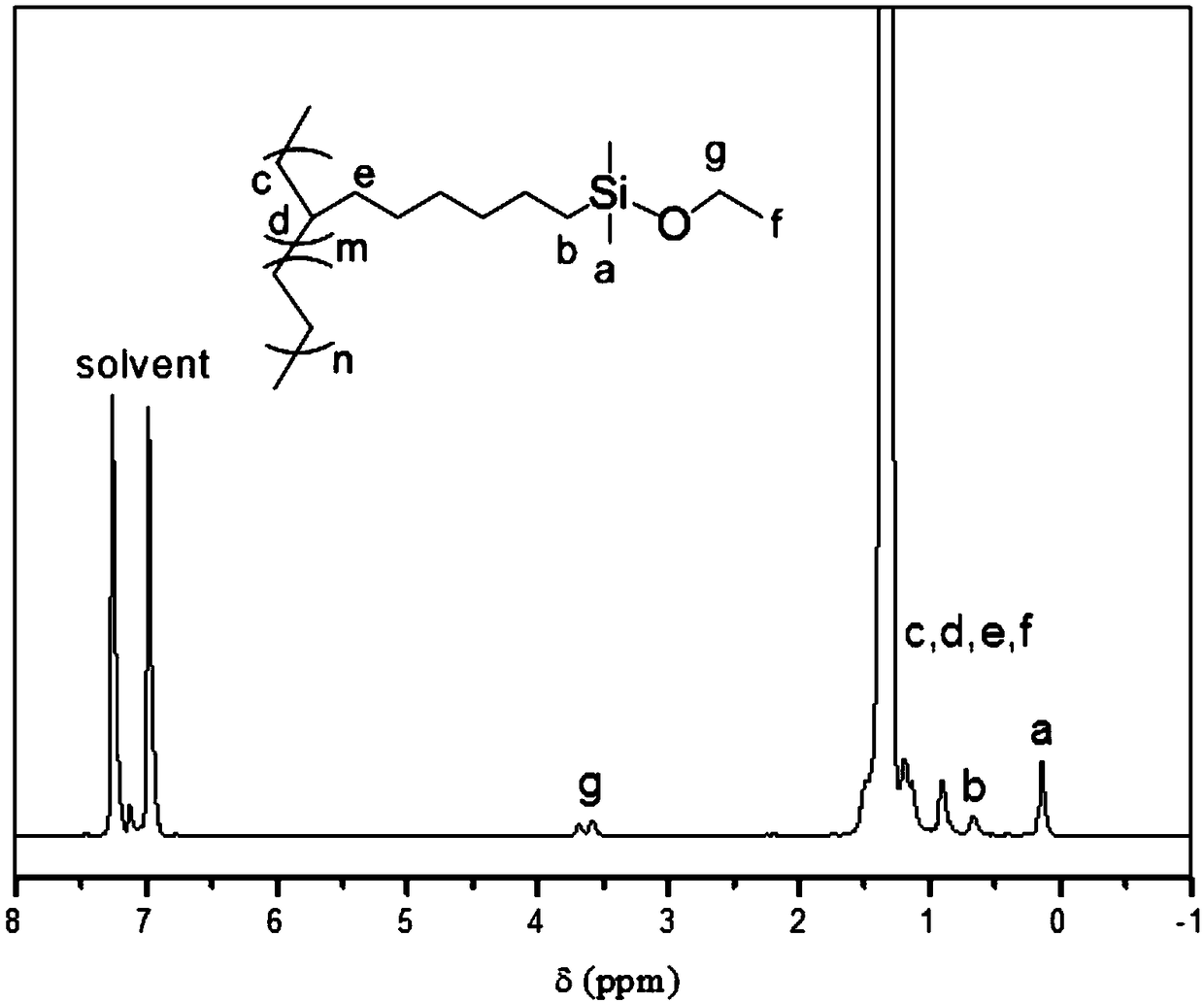

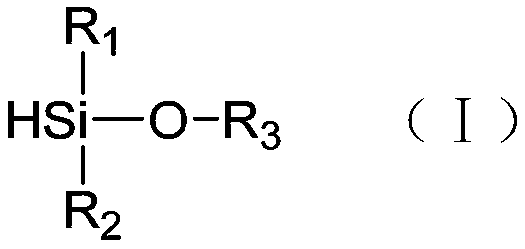

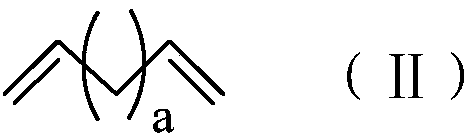

Preparation method of alkoxy silane-olefin copolymer as well as product and application thereof

The invention relates to a preparation method of an alkoxy silane-olefin copolymer. The preparation method comprises the following steps: firstly, carrying out hydrosilylation reaction on single hydrogen-terminated alkoxy silane and straight chain alpha, omega-diene under the action of a platinum catalyst to generate double bond-terminated alkoxy silane; secondly, carrying out coordinated copolymerization reaction on the double bond-terminated alkoxy silane and alpha-olefin under the action of a Ziegler-Natta vanadium-based main catalyst and a diethylaluminium chloride Et2AlCl cocatalyst system to generate the alkoxy silane-olefin copolymer. The invention also relates to a product obtained by the preparation method and application. By improving the method, the gel phenomenon is not caused during preparation of the alkoxy silane-olefin copolymer; in addition, the obtained product can be quickly crosslinked in an acidic environment; the content of the crosslinked gel reaches 10 to 100 percent, thereby realizing functional modification of a polyolefin material.

Owner:ZHEJIANG UNIV

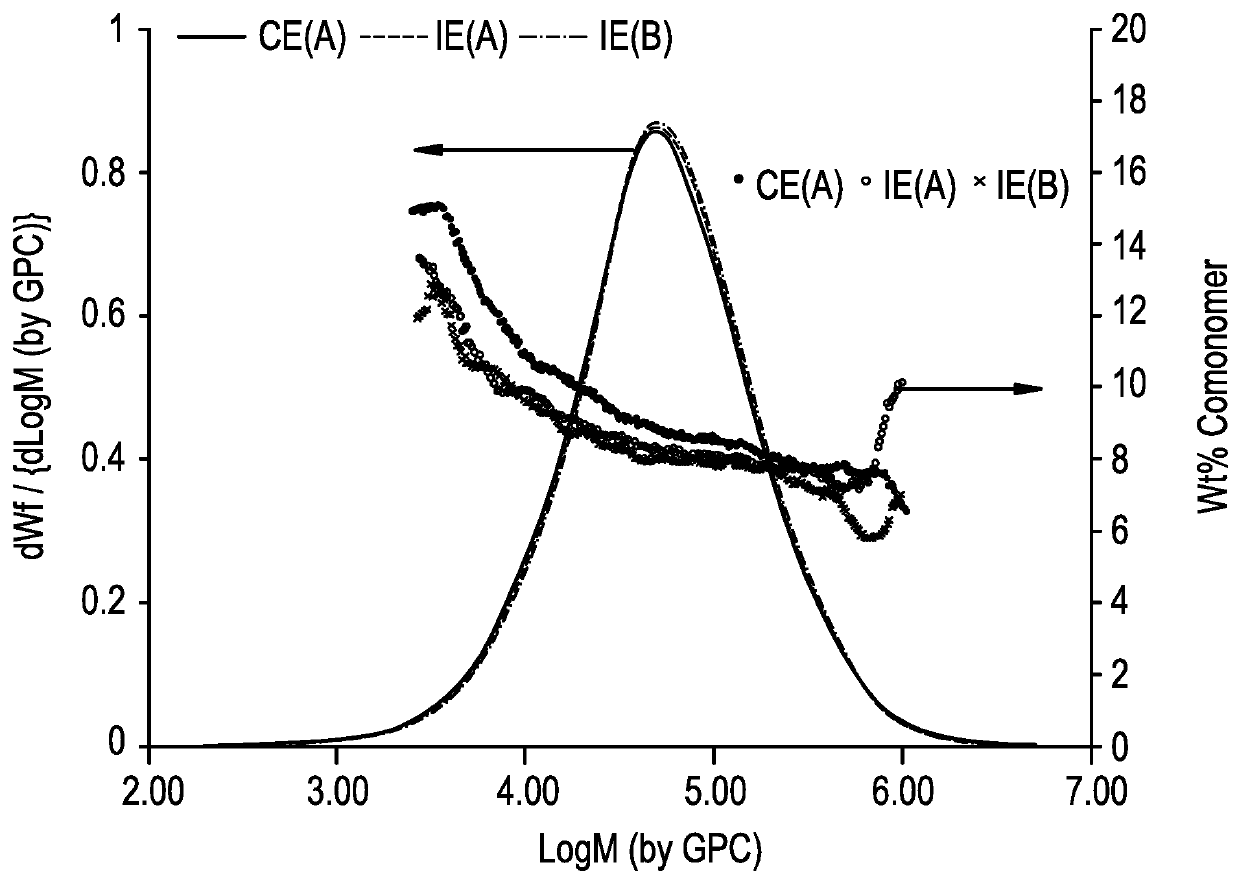

Activated spray-dried Ziegler-Natta catalyst system

ActiveUS11325927B2Increase ratingsImprove mechanical propertiesTitanium organic compoundsPolyolefinPtru catalyst

An activated, titanium-based, spray-dried Ziegler-Natta catalyst system containing a titanium-based Ziegler-Natta catalyst, a carrier material, and an activator mixture comprising an effective amount of an activator mixture comprising triethylaluminum and diethylaluminum chloride for producing a substantially uniform comonomer composition distribution. Also, polyolefins; methods of making and using same; and articles containing same.

Owner:UNIVATION TECH LLC

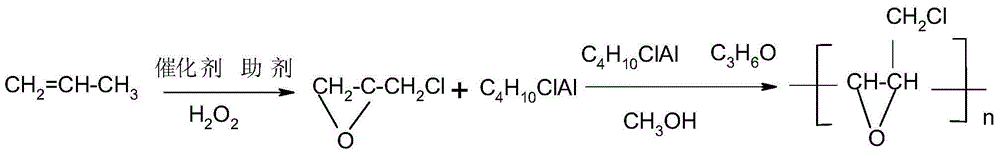

Method for synthesizing polyepichlorohydrin

The invention discloses a method for synthesizing polyepichlorohydrin. The method comprises the following steps: catalyzing chloropropane by using a catalyst and additives, thereby obtaining epoxy chloropropane for later use; sequentially adding diethyl aluminum chloride and absolute ether into a three-opening flask with a stirrer, stirring for 10 minutes, cooling to be 0 DEG C, dropwise adding epoxypropane to react for 30-50 minutes, sucking out the volatile matters in time, further adding a methanol solution containing sodium hydroxide, stirring at normal temperature for 50 minutes, and stopping the reaction; moving the reaction mixture into a liquid separation funnel, washing, layering, and washing the obtained coarse product by using 5% hydrochloric acid, 5% sodium bicarbonate and distilled water till being neutral; and reducing the pressure by using a rotational evaporator, thereby obtaining 8.23g of polyepichlorohydrin. The polyepichlorohydrin yield is greater than 84.9%.

Owner:CHANGZHOU UNIV

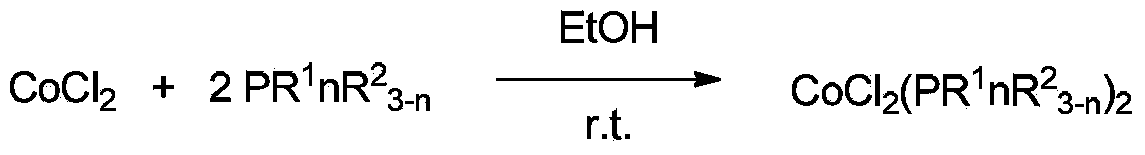

Two-component cobalt catalyst and application thereof in solution polymerization or suspension polymerization of 1,3-butadiene

The invention discloses a two-component cobalt catalyst and application thereof in solution polymerization or suspension polymerization of 1,3-butadiene. The cobalt catalyst comprises: (1) a main catalyst, wherein the general formula of the main catalyst is CoCl2(PR<1>nR<2>(3-n))2, and R1 and R2 are independently selected from hydrogen, alkyl group, naphthene group, benzyl group and aryl group; (2) a cocatalyst, wherein the cocatalyst is an alkyl aluminum chloride compound, including diethylaluminium chloride, ethylaluminium dichloride and sesquiethyl aluminum chloride. The main catalyst and the cocatalyst of the cobalt catalyst are mixed and aged for a period of time in a solvent according to a proportion or are supported on inert powder to be prepared into a supported catalyst; the 1,3-butadiene is added to perform solution polymerization or suspension polymerization. The two-component cobalt catalyst shows superior catalytic activity and high product cis-form selectivity in the polymerization of the 1,3-butadiene, and has wide industrial application prospect.

Owner:ZHEJIANG UNIV

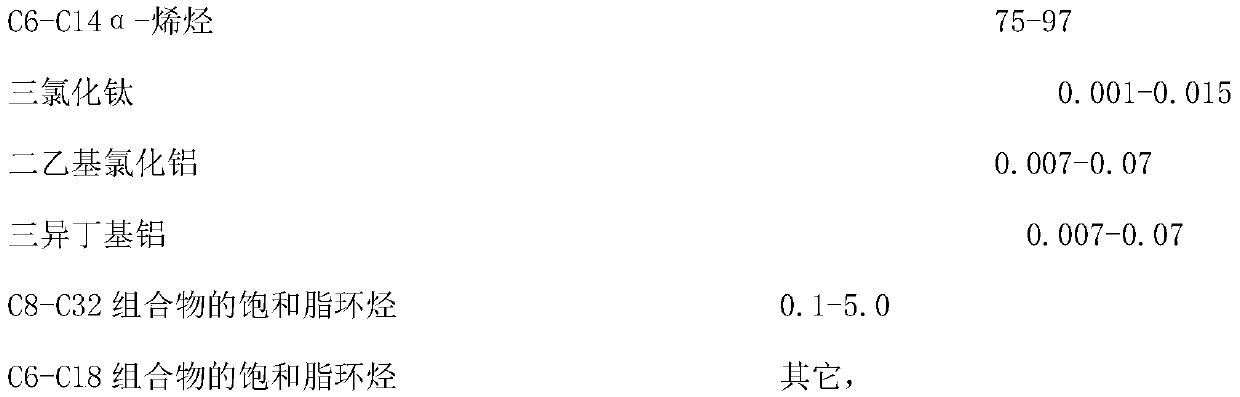

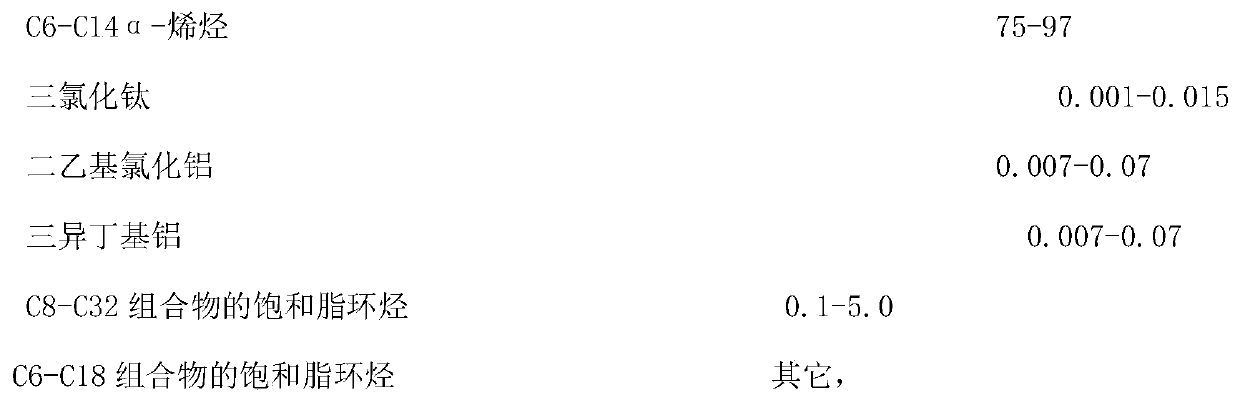

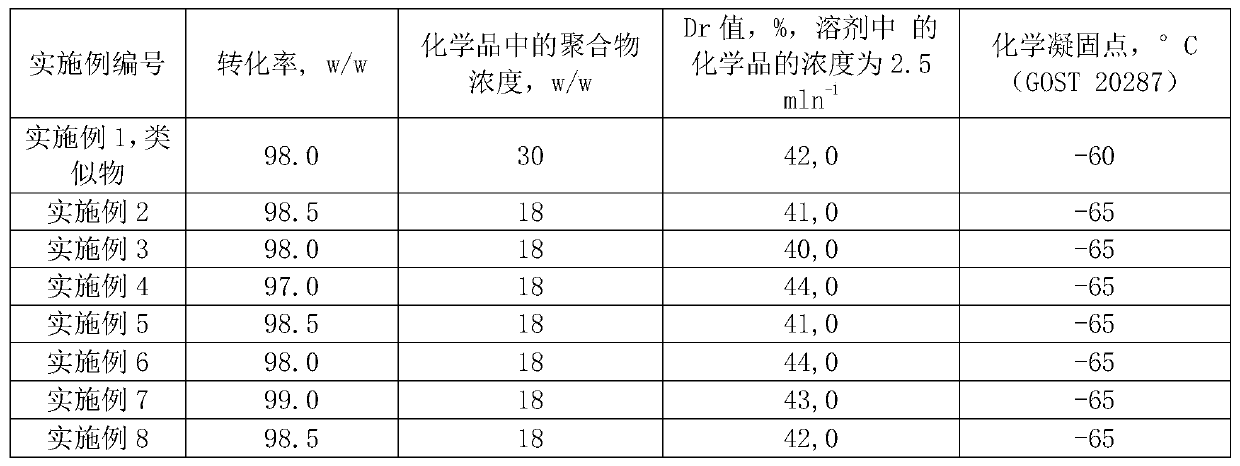

Method for producing a reagent to decrease hydrodynamic resistance of turbulent flow of liquid hydrocarbons in pipelines

InactiveCN110088143AReduce shipping costsLarge capacityLiquid carbonaceous fuelsPipeline systemsPetroleum productMass ratio

The invention relates to inorganic and polymer chemistry, and more specifically to the transport of oil and petroleum products via pipelines. A method for producing a reagent to decrease hydrodynamicflow resistance of liquid hydrocarbons in pipelines comprises polymerization of alpha-olefins C6-C14 in the presence of a catalyst and a catalyst activator. Furthermore, the polymerization of alpha-olefins C6-C14 is performed in a monomer medium with the addition of 0.1 to 5 mass percent of saturated alicyclic hydrocarbon composition C8-C32 and a saturated aliphatic hydrocarbon composition C6-C18with monomer conversion of 96.0 to 99.5 mass percent, wherein microspherical titanium trichloride is used as the catalyst, and a mixture of diethylaluminum chloride and triisobutylaluminum in a mass ratio of 1:10 to 10:1 is used as the catalyst activator. A polymer is then produced with a molecular mass of more than 107 amu with a narrow molecular mass distribution of no more than 1.5 with the specified component ratio. The polymer is then ground, thereby obtaining the commodity form of the reagent for decreasing hydrodynamic flow resistance of liquid hydrocarbons in pipelines. The technical result of the invention consists in producing a reagent that provides a decrease in the hydrodynamic resistance of the flow of liquid hydrocarbons in pipelines and, as a result, increases the throughput capacity of a pipeline and decreases the cost of transport.

Owner:OBSHCHESTVO S OGRANICHENNOJ OTVETSTVENNOSTJU MIRRIKO

n-5,6,7-hydroquinoline-8-arylimine nickel complex catalyst and its preparation method and application

ActiveCN105646597BGreat potential for industrial applicationsIncrease the degree of branchingNickel organic compoundsArylQuinoline

The present invention relates to a cycloalkyl-substituted N-5,6,7-hydro-quinoline-8-aryl imine nickel complex catalyst and a preparation method and application thereof. The N-5,6,7-hydro-quinoline-8-aryl imine nickel complex catalyst has a structural general formula as shown in a formula I. The catalyst complex can well catalyze vinyl polymerization under the effect of cocatalyst methylaluminoxane, diethylaluminium chloride and the like to obtain a low molecular weight high branching degree polymer, the catalyst complex also has high activity, the highest activity is up to 5.33*106g (PE) mol (Ni) <-1>h<-1>; the molecular weight of obtained polyethylene wax is 1430-3330g / mol, the molecular weight distribution is between 1.38-1.92, the branching degree is up to 422 / 1000C, and the catalyst complex has good prospects for industrial application.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Nickel(ii) complexes containing p-diphenylmethyl-substituted α-diimine for catalyzing the polymerization of ethylene and 2-hexene

ActiveCN107698699BSpeed up the walking processHigh activityNickel organic compoundsChain walkingPolymer science

Novel late-transition-metal alpha-diimine nickel (II) complexes containing p-benzhydryl substitutes are disclosed. According to the complexes, two bulky groups which are benzhydryl are introduced to the para positions of imine nitrogen atoms on aromatic rings, and therefore ethylene insertion is accelerated, catalyst activity is improved, the transferring rate of active chains to a monomer is reduced, and a polymer having a high molecular weight is prepared. Under activation by a cocatalyst that is diethylaluminium chloride, a catalytic system catalyzing ethylene polymerization has high catalytic activity (can be 10<6> g PE / (mol Ni h)), and prepared polyethylene having a high molecular weight has a high degree of branching (can be 131 branches per 1000 C). Because of ortho-position small-steric-hindrance substitution and immobilization by para-position bulky benzhydryl, 2-hexene can be easily inserted to a metal center, and therefore chain shuttling polymerization of the 2-hexene has ahigh conversion ratio (88%), and a branch polymer having a high molecular weight and a low degree of dispersion is obtained. Accordingly, the catalyst has good potential application value in industrial polyolefin production.

Owner:CHANGZHOU UNIV

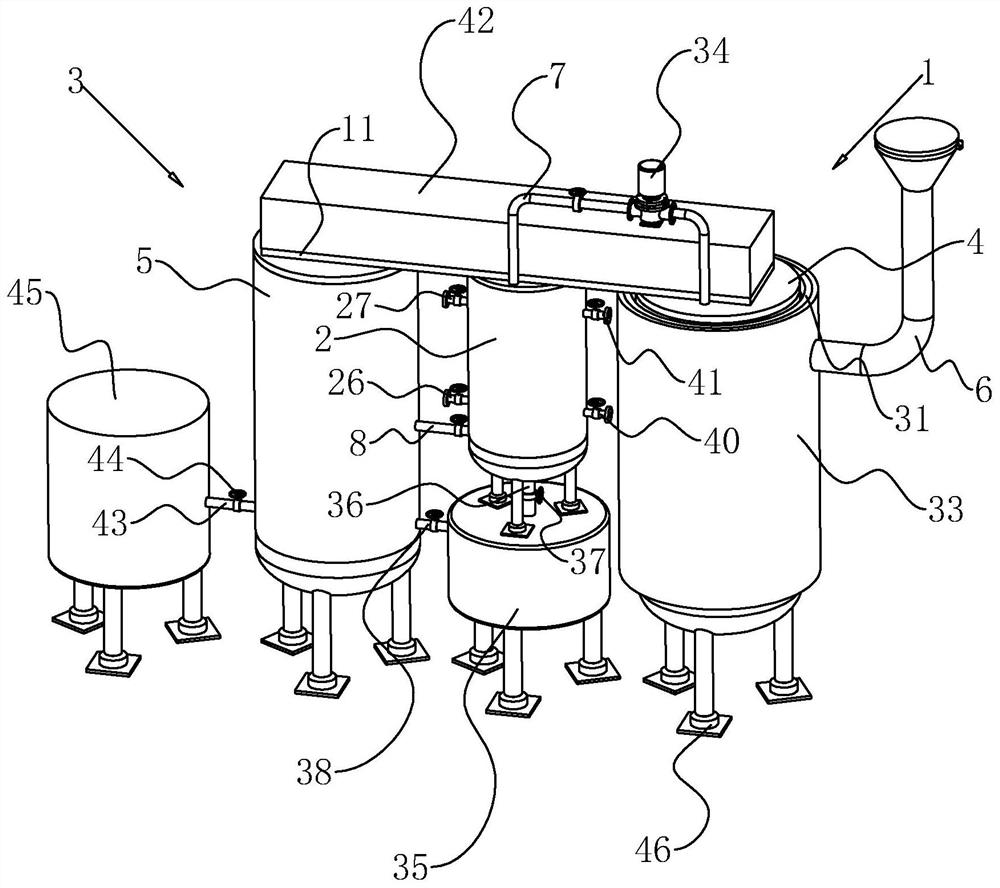

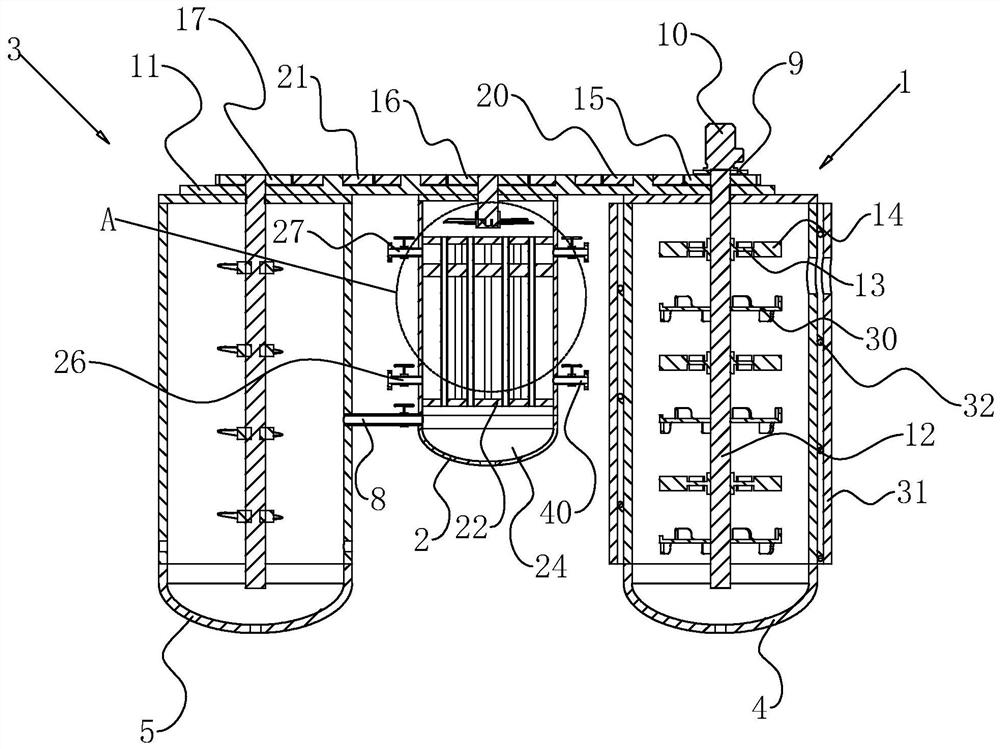

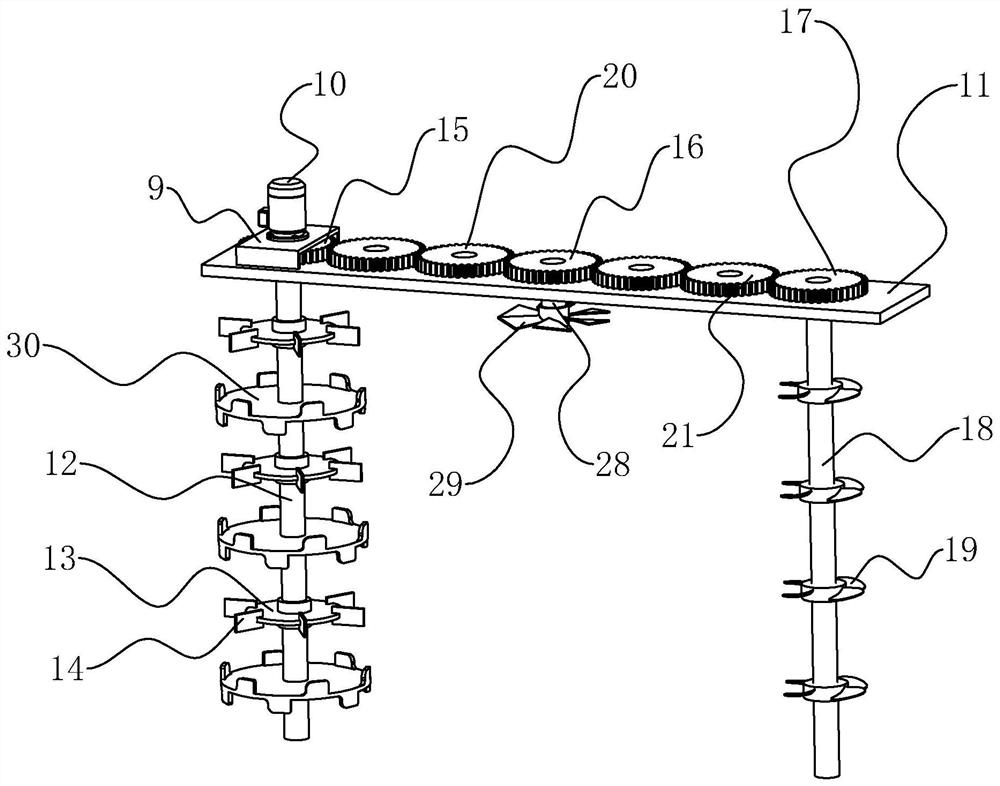

Preparation equipment and production process of diethylaluminium chloride mineral oil

ActiveCN112844284AIncrease reaction rateReduce usageTransportation and packagingRotary stirring mixersElectric machinePhysical chemistry

This application relates to preparation equipment and production process of diethyl aluminum chloride mineral oil. The preparation equipment comprises a reaction kettle, a condensation tank and a preparation stirring tank, the reaction kettle comprises a kettle body, the preparation stirring tank comprises a tank body, a motor is arranged above the kettle body, a strip-shaped plate is fixed to the kettle body, and a first stirring shaft is fixed to an output shaft of the motor; a plurality of discs are fixedly arranged on the first stirring shaft in the axial direction, a plurality of stirring blades are fixedly arranged on the discs, a first gear is fixedly connected to an output shaft of the motor, a second gear and a third gear are rotationally connected to the strip-shaped plate, a second stirring shaft is fixed to the third gear, and a plurality of stirring blades are fixedly arranged on the second stirring shaft; and a plurality of first transmission gears are arranged between the first gear and the second gear, and a plurality of second transmission gears are arranged between the second gear and the third gear. And the motor drives the second stirring shaft and the second stirring shaft to rotate, so that power equipment does not need to be independently used for driving the second stirring shaft to rotate, the use of the power equipment is reduced, and the production cost is reduced.

Owner:烟台联利化工有限公司

Three-tooth salicylaldehyde imine vanadium olefin polymerizing catalyst, preparation and uses thereof

The invention relates to a polymerization catalyst of tridentate salicylaldehyde imine vanadium alkene, a preparation method thereof and an application thereof. By the catalysis of formic acid, condensation reaction is carried out between the derivatives salicylaldehyde or salicylaldehyde, and amine compounds in methanol solution to obtain Schiff base; under the condition of no water and no oxygen, the Schiff base strips hydrogen protons and complexation reaction is carried out with vanadium trichloride to obtain the polymerization catalyst of tridentate salicylaldehyde imine vanadium alkene;by the action of aluminium diethyl monochloride, the polymerization catalyst is applied to catalyzing ethylene for polymerization; and by the action of aluminium diethyl monochloride, the polymerization catalyst is applied to the copolymerization of ethylene and 1-hexylene at 25 DEG C and used for catalyzing the copolymerization of ethylene and norbornene at the temperature of 50 DEG C. The polymerization catalyst has the advantages of convenient preparation, high catalytic activity, good heat stability, strong copolymerization capacity, etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

A kind of preparation method of alkoxysilane-olefin copolymer and its product and application

Owner:ZHEJIANG UNIV

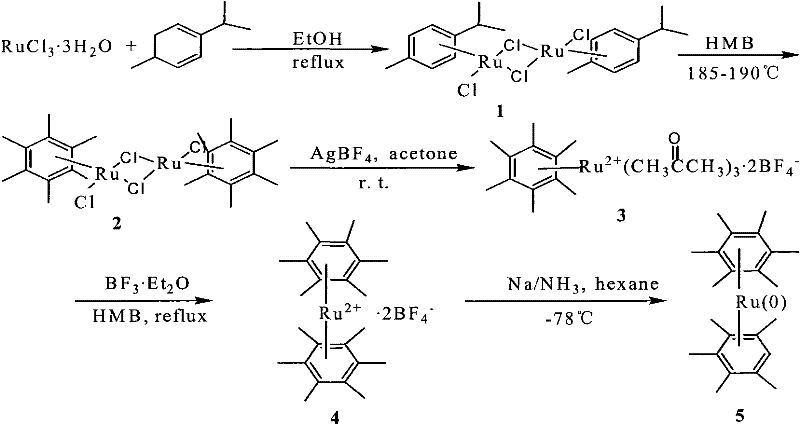

Novel process for preparing (C6Me6)2Ru organic metal complex

InactiveCN102234294ASynthetic reaction conditions are mildSuitable for industrial productionGroup 8/9/10/18 element organic compoundsOxygenHomogeneous catalysis

Ruthenium is a transition metal element, has multiple valence states and complicated coordination states and can form various organic complexes. The bivalent ruthenium organic compound is the most common, and researches on the trivalent and the nulvalent ruthenium organic complexes are fewer. [C6Me6]2Ru is similar to ferrocene in shape and has a bread sandwich structure. E.O.Fischer firstly reports the synthesis of the compound [C6Me6]2Ru; aluminum powder and diethyl aluminum chloride used in the reaction have active chemical properties and can be oxidized and even burn and explode in air; and aluminum trichloride and aluminum tribromide are very sensitive to water. A Fischer [C6Me6]2Ru synthesis technology comprises four steps, wherein three steps need to be performed in an anhydrous and oxygen-free condition, reactants and reagents need to be dehydrated and deoxidized, the safety coefficient of a preparation process is low and the total yield is lower and is 19% only (in terms of RuCl3). The invention develops a brand new synthesis design way, in which RuCl3 hydrate is adopted as a raw material, four steps are performed for synthesis and reaction to prepare the [C6Me6]2Ru; the yield of the novel process reaches 39%, which is improved by 20% compared with that of the E.O.Fischer synthesis technology, and the reagents used in the synthesis process are stable and readily available; except for the last step of sodium ammonia reduction, dehydration and deoxidization are not needed in the other three steps, therefore, the operation technology process is simplified, the safety coefficient is raised, and the novel process is suitable for the industrialized production. The organic metal Ru(O) complex which is wide in application range is a potential homogeneous catalyst, can be applied to catalysis of aromatic hydrogenation and asymmetrical catalysis, and can also be applied to the field of clinical medicaments to serve as a novel anti-cancer medicament.

Owner:BEIJING UNIV OF CHEM TECH

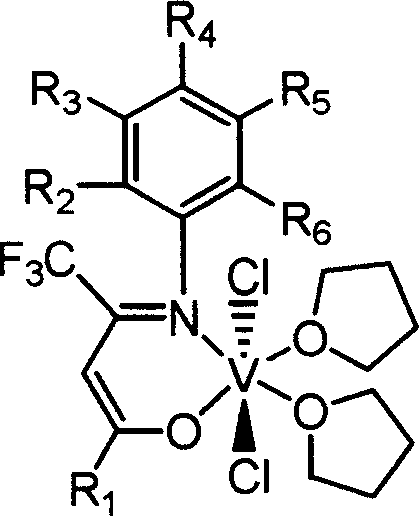

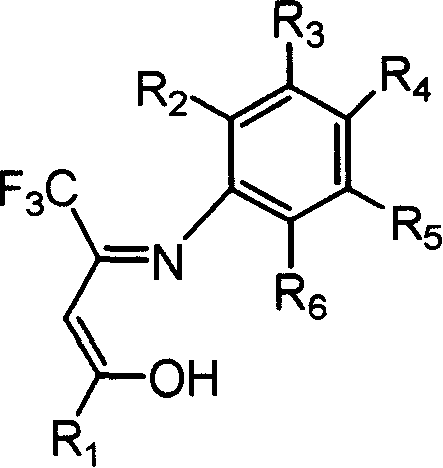

Beta-diketone monoimine vanadium catalyst containing trifluoromethyl radical for olefinic polymerization and its preparation method and uses

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Single-salicylaldehyde imine vanadium olefin polymerization catalyst as well as preparation method and use thereof

The invention relates to a method for preparing single salicylaldehyde imine vanadium olefin polymerization catalyst and application of the catalyst in catalyzing ethylene polymerization. Under the catalyzing effect of formic acid, condensation reaction of the salicylaldehyde or derivatives of the salicylaldehyde and aniline or derivatives of the aniline is carried out in methanol solution, and skiff base is obtained. Under the condition of no water and no oxygen and under the effect of excess triethylamine, the single salicylaldehyde imine vanadium olefin polymerization catalyst of the invention is obtained by complexation reaction of the skiff base and vanadium trichloride. Under the effect of diethyl aluminium chloride, the catalyst of the invention can be used for catalyzing ethylene polymerization. The invention has the advantages of easy preparation, high catalyzing activity and good thermal stability.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Anti-corrosion pipeline material for water supply equipment and preparation method of anti-corrosion pipeline material

The invention discloses an anti-corrosion pipeline material for water supply equipment. The anti-corrosion pipeline material is prepared from raw materials in parts by weight as follows: 3-10 parts of polyethylene resin, 5-10 parts of nano-particles, 5-10 parts of carbon black, 2-7 parts of hydrogenated castor oil, 2-10 parts of alkyl sodium sulfonate, 2-7 parts of chlorofluoromethane, 3-11 parts of diethylaluminium chloride, 1-3 parts of an acrylonitrile-butadiene-styrene copolymer, 3-9 parts of a silane coupling agent, 2.5-4.5 parts of an antioxidant, 0.5-6.5 parts of an anticorrosive agent and 1.5-3.5 parts of a lubricating agent. According to the anti-corrosion pipeline material for the water supply equipment and a preparation method of the anti-corrosion pipeline material, the pipeline material is prepared with the appropriate method from appropriate raw materials by selecting and blending, and the pipeline material prepared from the polyethylene resin as the raw material has good mechanical properties, is impact-resistant, anti-corrosion and anti-aging, and has excellent overall performance.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

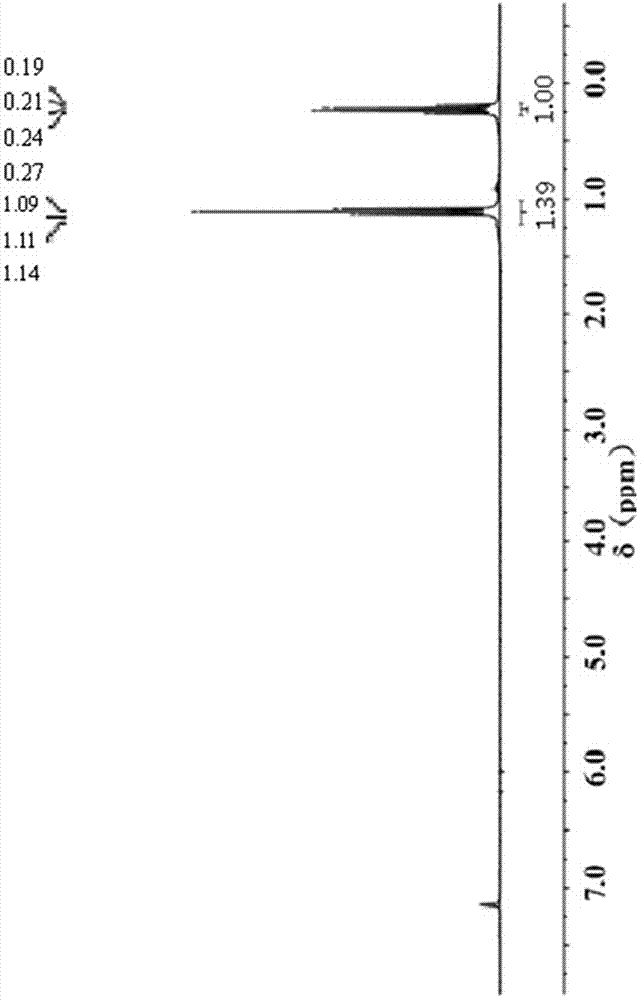

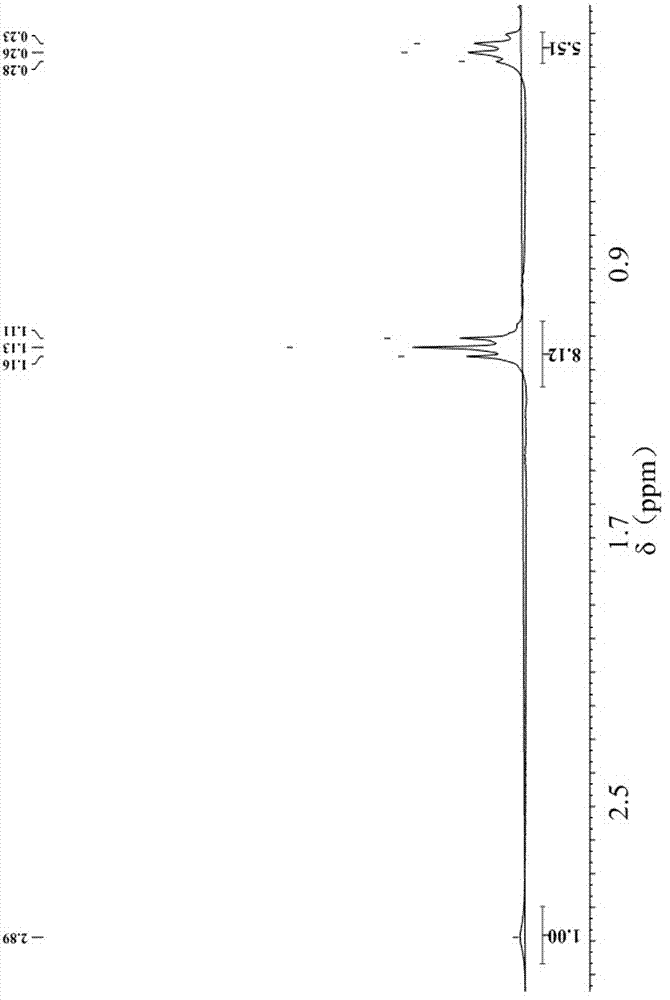

Preparation method of diethyl aluminum hydride

InactiveCN104774217AStrong reductionCharacterized by high purityGroup 3/13 element organic compoundsDistillationReaction temperature

The invention discloses a preparation method of diethyl aluminum hydride. The preparation method comprises the following steps: (1) adding 80-120ml of diethyl aluminum hydride (Et2AlCl) to 500ml of three-mouth round-bottom flask, slowly adding 160-200ml of solvent under a stirring condition, and then further stirring for 20-40 minutes; (2) controlling the temperature to be not greater than 60 DEG C, slowly adding 40-42g of LiAlH4, fully mixing, heating in an oil bath, controlling the reaction temperature to be 100-110 DEG C and reacting for 3-5 hours; (3) after reacting, cooling, carrying out rotary evaporation at 50-60 DEG C until no liquid is evaporated, and then filtering to remove grey solid substances; and (4) carrying out reduced pressure distillation on filtrate, and collecting fractions at 102 DEG C, thereby obtaining a colorless transparent liquid as a target product. The diethyl aluminum hydride prepared by the method is high in purity and high in yield and has great potential industrial value.

Owner:HARBIN INST OF TECH

High Rigid Linear Low Density Polyethylene Injection Molding Resin

ActiveCN104292595BImprove balanceEasy to processLow-density polyethyleneLinear low-density polyethylene

The invention relates to a high-rigid linear low-density polyethylene injection moulding resin which is prepared from following substances including, by weight, 100 parts of linear low-density polyethylene, 0.15-0.3 parts of a photo-stabilizing agent, 0.05-0.15 parts of an anti-oxygen agent, 0.02-0.10 parts of a halogen absorbing agent, and 0.05-0.10 parts of a rheology modifier. The linear low-density polyethylene is prepared from a following method comprising a step of polymerization through a Unipol gas-phase technology with ethylene as a raw material, 1-butylene as a co-polymer monomer, hydrogen as a chain transfer agent, SLC-S as a catalyst and diethylaluminium chloride and tri-n-hexylaluminium as co-catalysts. The high-rigid linear low-density polyethylene injection moulding resin is good in resin uniformity, rigid-flexible balanced performance and processability, has an excellent anti-ultraviolet light aging property and is mainly used in injection moulding of outdoor products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com