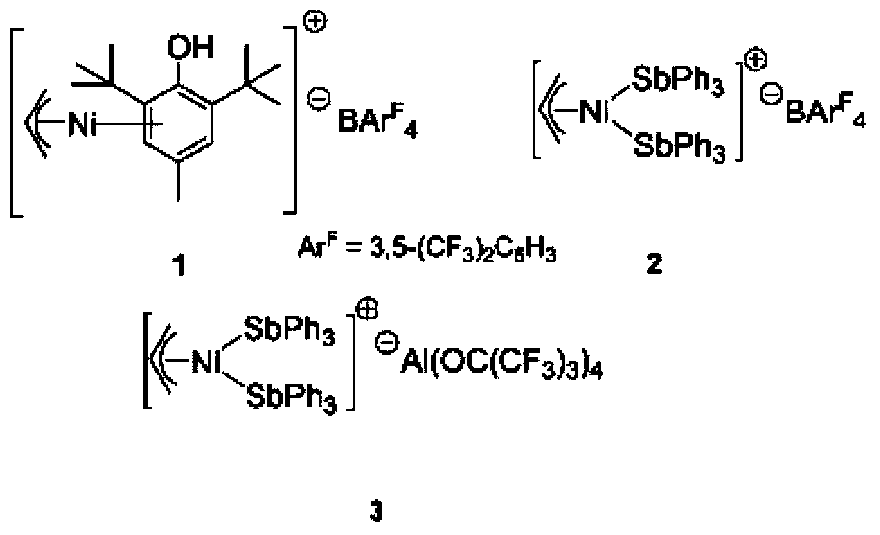

Two-component cobalt catalyst and application thereof in solution polymerization or suspension polymerization of 1,3-butadiene

A suspension polymerization, two-component technology, used in the field of two-component catalysts, can solve the problems of low catalytic activity and easy agglomeration of polymer particles, and achieve high product cis-selectivity, excellent catalytic activity, and broad industrial application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

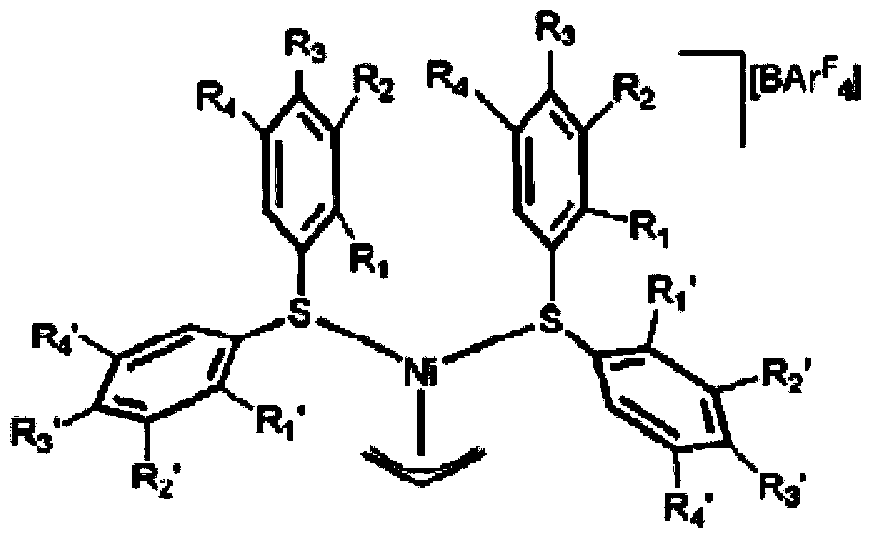

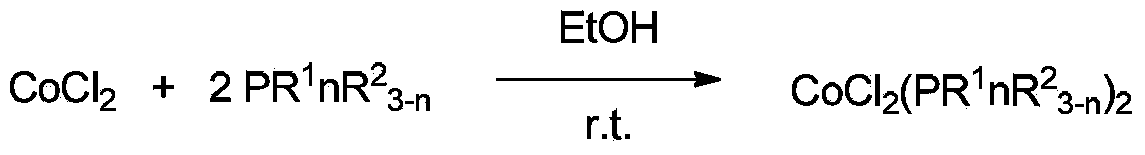

Method used

Image

Examples

Embodiment 1

[0032] Under nitrogen protection, take 3.3 mg (5.0 μmol) of the main catalyst CoCl 2 (PPh 3 ) 2 In a Schlenk bottle, seal it with a rubber stopper, vacuumize and blow nitrogen three times, and add 5 mL of purified toluene solvent. Then, add 0.5 mL of cocatalyst sesquiethylaluminum chloride (EASC, 0.4 mol / L n-hexane solution) with a syringe, so that [Al] / [Co] is 80 (molar ratio, the same below), the catalyst The composition was stirred and aged at 25°C for two minutes, and then 1.4 mL of 1,3-butadiene (1.86 mol / L toluene solution) was added with a syringe to make the monomer 1,3-butadiene and the main The molar ratio of metal cobalt in the catalyst is 500, and the polymerization reaction starts to proceed. After one hour, a uniform and transparent reaction solution was obtained, and the reaction solution was poured into 200mL terminator to terminate the polymerization. as an antioxidant). The precipitated polybutadiene rubber (PBD) was filtered, washed several times with a...

Embodiment 2

[0034] The specific operation steps are the same as in Example 1, taking 3.3 mg (5.0 μmol) of the main catalyst CoCl 2 (PPh 3 ) 2 , add 5mL of purified benzene solvent, and add 5.5mL of 1,3-butadiene (1.85mol / L benzene solution) with a syringe, so that the mole of monomer 1,3-butadiene and metal cobalt in the main catalyst The ratio was 2000, the polymerization temperature was 25°C, and the polymerization time was one hour.

Embodiment 3

[0036] The specific operation steps are the same as in Example 1, taking 3.3 mg (5.0 μmol) of the main catalyst CoCl 2 (PPh 3 ) 2 , add 5mL of purified ethylbenzene solvent, and add 8.5mL of 1,3-butadiene (1.84mol / L ethylbenzene solution) with a syringe, so that the monomer 1,3-butadiene and the metal cobalt in the main catalyst The molar ratio is 3000, the polymerization temperature is 25°C, and the polymerization time is one hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com