High-rigid linear low-density polyethylene injection moulding resin

A linear low-density polyethylene technology, applied in the field of polymer materials, can solve the problems of no UV aging resistance, low weather resistance and rigidity, reduced material fluidity, toughness and other comprehensive physical properties, and achieve excellent durability Effect of UV aging resistance and good resin uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

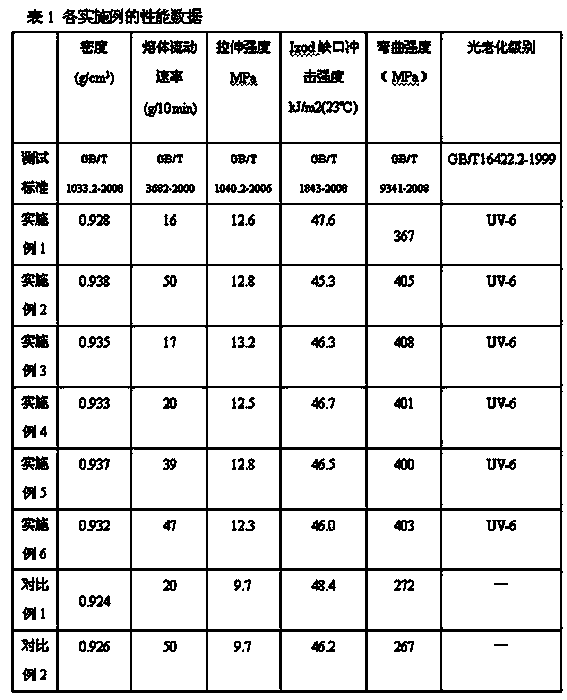

Examples

Embodiment 1

[0036] A high-rigidity linear low-density polyethylene injection molding resin is prepared from the following materials in parts by weight:

[0037] Linear Low Density Polyethylene 100 parts

[0038] Light stabilizer 944 0.1 parts

[0039] Light stabilizer 119 0.1 parts

[0040]Bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate 0.05 parts

[0041] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.10 parts

[0042] Zinc stearate 0.08 parts

[0043] 0.10 parts of oleic acid amide;

[0044] After the above materials are mixed, the high rigidity linear low density polyethylene injection molding resin is obtained after granulation and packaging.

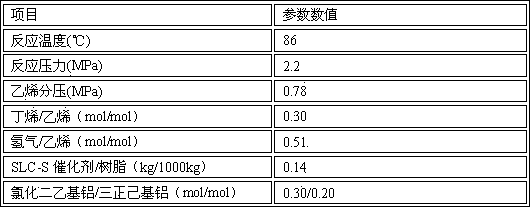

[0045] The above linear low density polyethylene is prepared by the following method: using ethylene as raw material, 1-butene as comonomer, hydrogen as chain transfer agent, SLC-S catalyst, diethylaluminum chloride and tri-n-hexylaluminum As a cocatalyst, it is polymerized by Unipol gas phase process...

Embodiment 2

[0049] A high-rigidity linear low-density polyethylene injection molding resin is prepared from the following materials in parts by weight:

[0050] Linear Low Density Polyethylene 100 parts

[0051] Poly[1-(2'-hydroxyethyl)-2.2.6.6-tetramethyl-4-hydroxypiperidine succinate] 0.2 parts

[0052] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.05 parts

[0053] Tris(2,4-di-tert-butylphenyl)phosphite 0.1 part

[0054] Hydrotalcite 0.02 part

[0055] Erucamide 0.10 parts;

[0056] After the above materials are mixed, the high rigidity linear low density polyethylene injection molding resin is obtained after granulation and packaging.

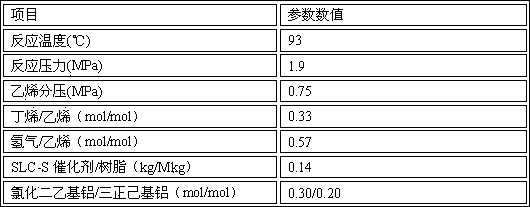

[0057] The above linear low density polyethylene is prepared by the following method: using ethylene as raw material, 1-butene as comonomer, hydrogen as chain transfer agent, SLC-S catalyst, diethylaluminum chloride and tri-n-hexylaluminum As a cocatalyst, it is polymerized by the Unipol gas phase process; th...

Embodiment 3

[0061] A high-rigidity linear low-density polyethylene injection molding resin is prepared from the following materials in parts by weight:

[0062] Linear Low Density Polyethylene 100 parts

[0063] Light stabilizer 944 0.15 parts

[0064] 1,3,5,tris(3,5-di-tert-butyl,4-hydroxybenzyl)-s-triazine-2,4,6-(1H,3H,5H)trione 0.10 parts

[0065] Tris(2,4-di-tert-butylphenyl)phosphite 0.05 parts

[0066] Zinc stearate 0.1 parts

[0067] 0.08 part of polyvinylidene fluoride resin;

[0068] After the above materials are mixed, the high rigidity linear low density polyethylene injection molding resin is obtained after granulation and packaging.

[0069] The above linear low density polyethylene is prepared by the following method: using ethylene as raw material, 1-butene as comonomer, hydrogen as chain transfer agent, SLC-S catalyst, diethylaluminum chloride and tri-n-hexylaluminum As a cocatalyst, it is polymerized by the Unipol gas phase process; the process parameters and the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com