Expansion device and processing method for facing of large-size medium-thickness cylindrical part

A large-size, car-end technology, which is applied to the field of expansion devices for large-size medium-thick plate cylindrical parts, can solve the problems of inconvenient actual production, self-heaviness and inconvenience of thick plate cylindrical parts, and achieve major social benefits And economic benefits, easy engineering application, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

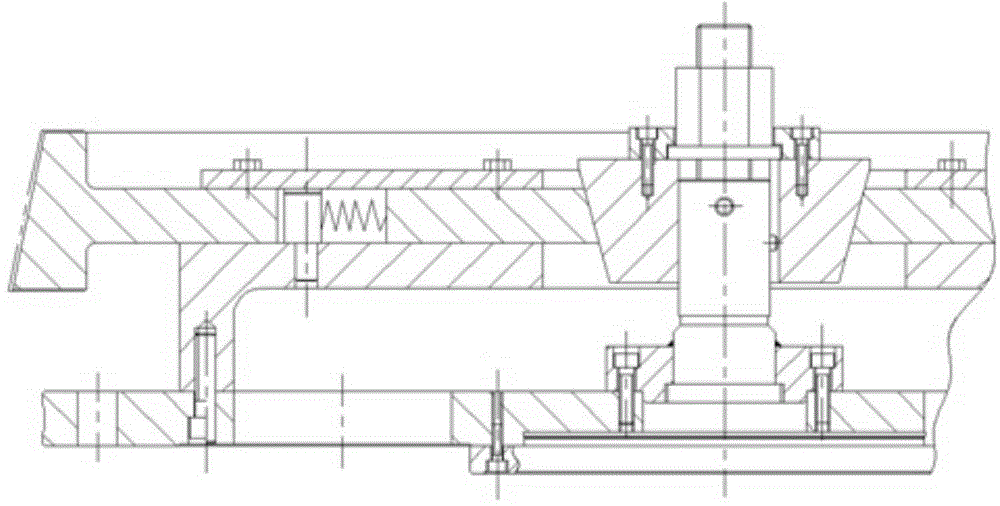

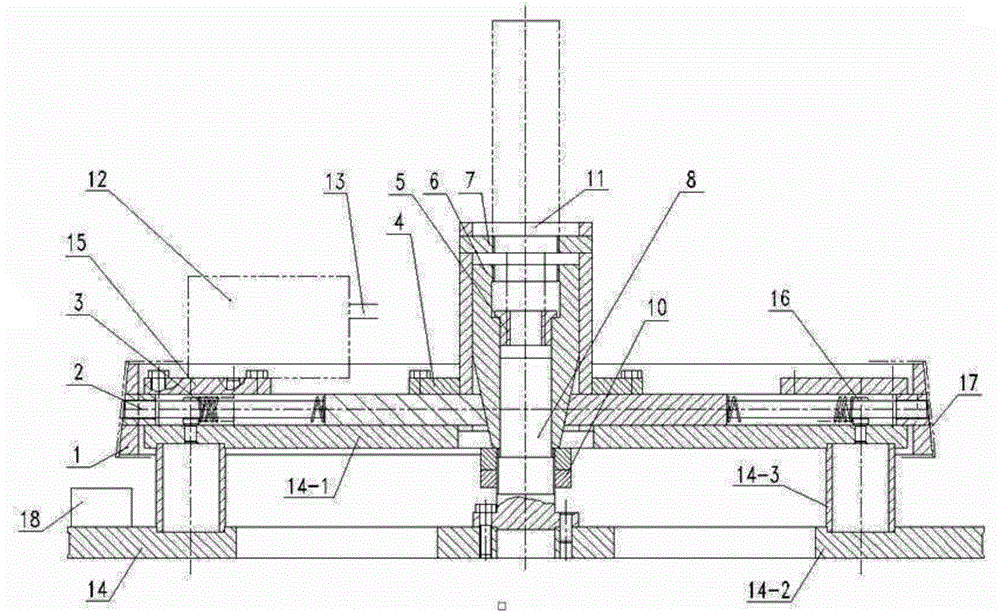

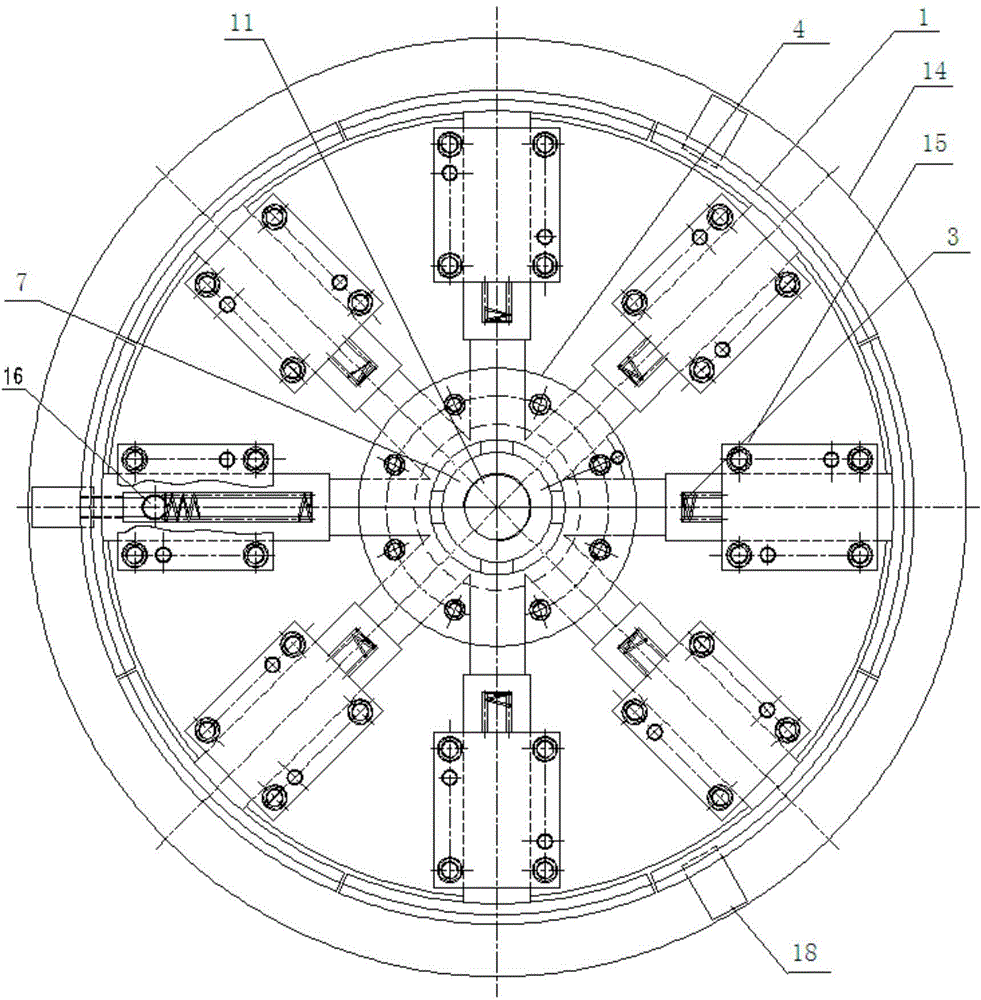

[0036] like Figure 2-10 As shown, the tensioning device used for the end face of the large-sized medium-thick plate cylindrical part, the device includes a base 14, a guide plate 15, an expansion block 1, a guide seat 4, an expansion head 5, a cone head 6, and a support plate 7 , guide column b8, slack top 9, single-acting hydraulic cylinder 11, manual hydraulic pump 12 and high-pressure hydraulic oil pipe 13; the base 14 is composed of an upper support plate 14-1, a lower support plate 14-2, and circumferentially evenly distributed pillars 14-3 Welding, the guide seat 4 is fixed on the upper support plate 14-1 of the base 14 by bolts, the guide seat 14 is provided with an inner cavity, and the guide post b8 is fixed on the lower support plate of the base 14 by bolts 14-2, the guide seat 4, the guide post b8, and the base 14 are arranged coaxially;

[0037]The cone head 6 is provided with a cone head inner hole, the cone head 6 is placed in the inner cavity of the guide seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com