Polishing-free mirror surface type stone-like flexible sheet and preparation method thereof

A kind of stone flexible and sheet technology, which is applied in the field of preparation of non-polishing mirror type stone imitation flexible sheet and non-polishing mirror type stone imitation flexible sheet, which can solve the problem of high requirements for construction operation of exterior wall imitation stone paint and natural stone self-sufficiency. Major problems, insufficient elasticity, etc., to achieve the effect of no risk of fragmentation, light weight, and fast drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

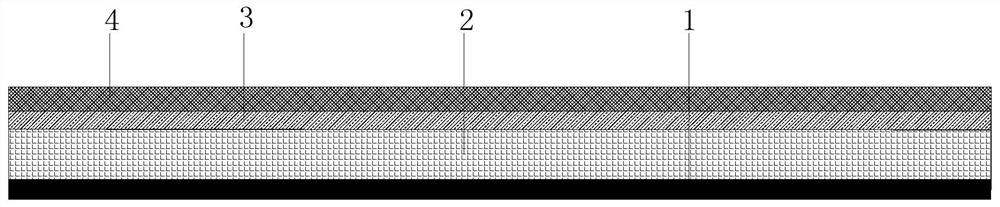

Image

Examples

preparation example Construction

[0034] Another aspect of the present invention provides a method for preparing a polishing-free mirror-like stone-like flexible sheet described in any of the above-mentioned embodiments, which includes the following steps:

[0035] S10, coating 100-200g / m on the high temperature resistant base cloth 2 Polish-free mirror coating, and then use equipment to evenly coat 200-600g / m on the non-polishing mirror coating 2 The flexible dry and wet rock slices are dried in a drying equipment at 60-100°C for 10-30 minutes;

[0036] S20, using recovery equipment on the high-temperature-resistant base cloth to recycle the excess flexible wet and dry rock slices, and spray or roll 50-150g / m on the flexible wet and dry rock slices at the same time 2 Waterproof and reinforced coating, and then enter the drying equipment at 60-100°C for 10-30 minutes;

[0037] S30, coating 3000-4000g / m on the waterproof reinforcement coating 2 Flexible waterproof cushion and add 60-150g / m 2 The grid cloth ...

Embodiment 1

[0044] Embodiment 1: Example of polishing-free mirror coating

[0045] The components contained in the polishing-free mirror coating and the weight percentages of each part are:

[0046] serial number Material name and specification Example 1 Example 2 Example 3 1 Water-based fluorocarbon resin emulsion 60.0 / / 2 Waterborne Polyurethane Dispersion / 60.0 / 3 Waterborne Acrylic Emulsion / / 70.0 4 Polysiloxane Surfactants 0.60 0.70 0.80 5 Nano fumed silica 1.5 2 1 6 Polydimethylsiloxane 0.50 0.50 0.60 7 20% Ethoxylated Waterborne Polyurethane 2 2.5 3 8 Methylisothiazolinone 0.20 0.30 0.40 9 water 35.2 34.0 24.2

[0047] Make the above no-polish mirror coating example into a slurry:

[0048] Under the condition of rotating speed of 300-500r / min, add water, polysiloxane surfactant, polydimethylsiloxane, and methylisothiazolinone to the dispersion container in order to disperse ...

Embodiment 2

[0050] Embodiment 2: Example of waterproof and reinforced coating

[0051] The components contained in the waterproof and reinforced coating and the weight percentages of each part are:

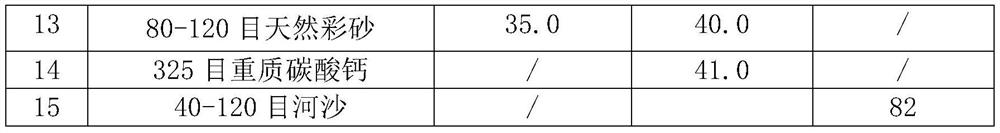

[0052] serial number Material name and specification Example 1 Example 2 Example 3 1 Silicone acrylic emulsion 45.0 / / 2 Silicon modified acrylic emulsion / 50.0 / 3 Waterborne Acrylic Emulsion / / 55.0 4 Polysiloxane Surfactant 0.60 0.70 0.80 5 dodecyl alcohol ester 2.00 2.50 3.00 6 Polydimethylsiloxane 0.40 0.50 0.60 7 20% Ethoxylated Waterborne Polyurethane 1.0 1.5 0.5 8 Methylisothiazolinone 0.20 0.30 0.40 9 water 50.8 44.5 39.7

[0053] Make the above examples of waterproof reinforcement coating into slurry:

[0054] Under the condition of rotating speed of 300-500r / min, add water, polysiloxane surfactant, polydimethylsiloxane, methylisothiazolinone, dodecyl alcohol ester into the disper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com