Method for producing a reagent to decrease hydrodynamic resistance of turbulent flow of liquid hydrocarbons in pipelines

A technology of fluid mechanics and liquid hydrocarbons, applied in pipeline systems, liquid carbon-containing fuels, gas/liquid distribution and storage, etc., can solve problems such as low monomer conversion rate, low polymer concentration, and wide molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

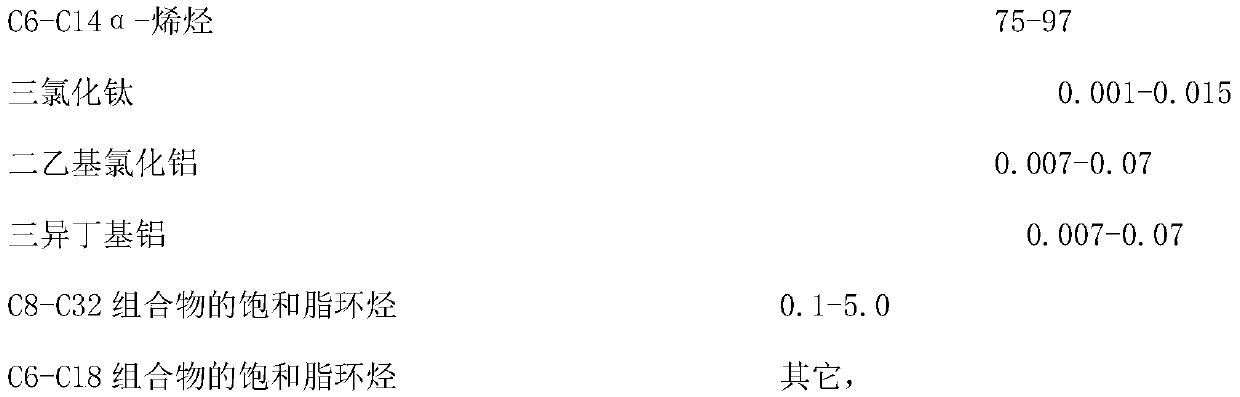

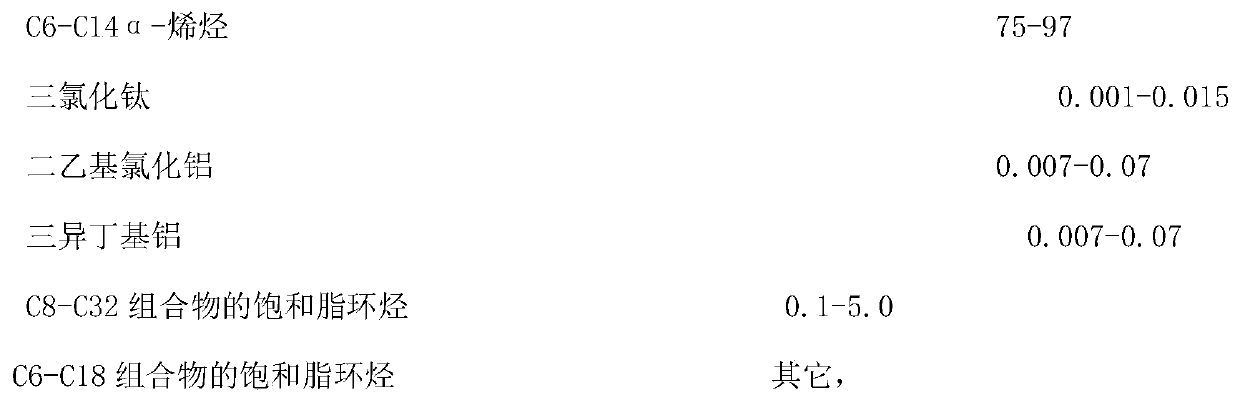

Method used

Image

Examples

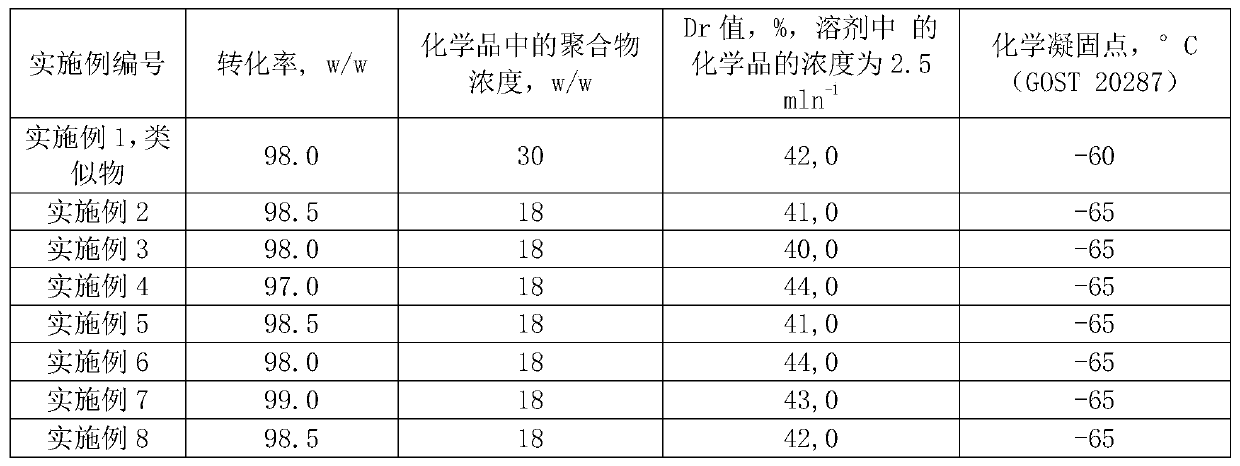

Embodiment 1

[0042] Example 1 (similar to RU 2599245)

[0043] Jacketed reactor with mixer, thermocouple, pressure gauge, nitrogen delivery 99.9% w / w filled with 90% w / w amount of hexane-1, 5% w / w amount of tetradecane The ene-1, 4.91% w / w amount of dodecane with a purity of not less than 99.8% w / w. The mixture in the reactor was cooled to +10±2°C by mixing with a mixer and feeding the coolant into the jacket of the reactor. The catalyst activator was then delivered in the form of a mixture of diethylaluminum chloride and triisobutylaluminum in an amount of 0.077% w / w (0.0338% w / w each) in a weight ratio of 1:1 and the catalyst was delivered to Titanium trichloride in an amount of 0.013% w / w was fed into the reactor, ie as a suspension with a concentration of 40% w / w in heptane. The contents of the reactor were mixed, maintaining the temperature in the range of +8°C to +12°C for 1 hour. Then, the reaction mass was discharged in a nitrogen stream into an airtight container or a polymer c...

Embodiment 2

[0045] Jacketed reactor with mixer, thermocouple, pressure gauge, nitrogen delivery 99.9% w / w filled with 75% w / w amount of hexane-1, 10% w / w amount of decene- 1. Decalin with a purity of not less than 99.8% w / w in an amount of 11.91% w / w, and cyclooctadecane with a purity of not less than 99.8% w / w in an amount of 3.00% w / w. The mixture in the reactor was cooled to +10±2°C in a stream of nitrogen by mixing with a mixer and feeding the coolant into the jacket of the reactor. The catalyst activator was then delivered in the form of a mixture of diethylaluminum chloride and triisobutylaluminum in an amount of 0.077% w / w (0.0338% w / w each) in a weight ratio of 1:1 and the catalyst was delivered to the Titanium trichloride was fed in an amount of 0.013% w / w in the reactor, ie in the form of a suspension with a concentration of 40% w / w in heptane. The contents of the reactor were mixed, maintaining the temperature in the range of +8°C to +12°C for 1 hour. Then, the reaction mass ...

Embodiment 3

[0047]Jacketed reactor with mixer, thermocouple, pressure gauge, nitrogen delivery 99.9% w / w filled with 84% w / w amount of hexane-1, 5% w / w amount of tetradecane ene-1, dodecane with a purity of not less than 99.8% w / w in an amount of 5.91% w / w, cyclooctane with a purity of not less than 99.8% w / w in an amount of 5.00% w / w. The mixture in the reactor was cooled to +10±2°C by mixing with a mixer and feeding the coolant into the jacket of the reactor. The catalyst activator was then delivered in the form of a mixture of diethylaluminum chloride and triisobutylaluminum in an amount of 0.077% w / w (0.0338% w / w each) in a weight ratio of 1:1 and the catalyst was delivered to the Titanium trichloride was fed in an amount of 0.013% w / w in the reactor, ie in the form of a suspension with a concentration of 40% w / w in heptane. The contents of the reactor were mixed, maintaining the temperature in the range of +8°C to +12°C for 1 hour. Then, the reaction mass was discharged in a nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com