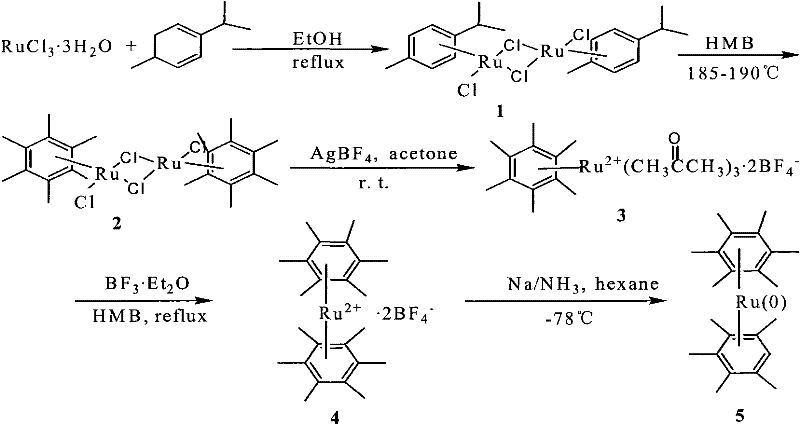

Novel process for preparing (C6Me6)2Ru organic metal complex

A technology of organometallic complexes, which is applied in the field of synthesis process development of organometallic complexes, can solve the problems of low overall yield and low safety factor in the preparation process, achieve high yield, reduce production cost and operation difficulty, The effect of reagent stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Take 0.300 g of RuCl 3 ·3H 2 O, 1.8mL phellandrene, and 18mL absolute ethanol were placed in a 50mL single-necked flask, reacted at reflux temperature for 4 hours, then stopped the reaction, naturally cooled to room temperature, and then stood still for 10 hours at -22°C, with reddish-brown Crystals were formed, filtered, and the filter cake was washed with absolute ethanol at 4°C to obtain a reddish-brown crystal product. The filtrate was concentrated by vacuum distillation, and the concentrated solution was repeated to recover the product in the filtrate, combined and dried in a vacuum oven at 80°C for 1 hour to obtain [RuCl 2 (C 10 h 14 )] 2 The product is 0.300 g, and the product yield is 67.7%.

[0023] 2) Take 3.800 g of hexamethylbenzene raw material and place it in a reactor at 165° C. until the hexamethylbenzene is completely melted, and raise the temperature of the reactor to 178° C. Get the [RuCl of step 1) preparation 2 (C 10 h 14 )] 2 Product 0...

Embodiment 2

[0027] 1) Take 0.222 grams of RuCl 3 ·3H 2 O, 1.1mL phellandrene, and 10mL absolute ethanol were placed in a 25mL single-necked flask, reacted at reflux temperature for 4 hours, then stopped the reaction, naturally cooled to room temperature, and then stood still for 10 hours at -22°C, with reddish-brown Crystals were formed, filtered, and the filter cake was washed with absolute ethanol at 4°C to obtain a reddish-brown crystal product. The filtrate is concentrated by vacuum distillation, and the concentrated solution repeats the above operations to reclaim the product in the filtrate, merges and dries the product to obtain [RuCl 2 (C 10 h 14 )] 2 The product is 0.199g, and the product yield is 77%.

[0028] 2) Take 3.000 g of hexamethylbenzene raw material and place it in a reactor at 165° C. until the hexamethylbenzene is completely melted, and raise the temperature of the reactor to 175° C. Get the [RuCl of step 1) preparation 2 (C 10 h 14 )] 2 Product 0.300 gram,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com