Preparation method of sunshade net with self-cleaning function

A technology of self-cleaning and sunshade nets, which is applied in the direction of sunshade, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low photocatalytic degradation rate and limit practical application, and achieve less process , easy to control, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

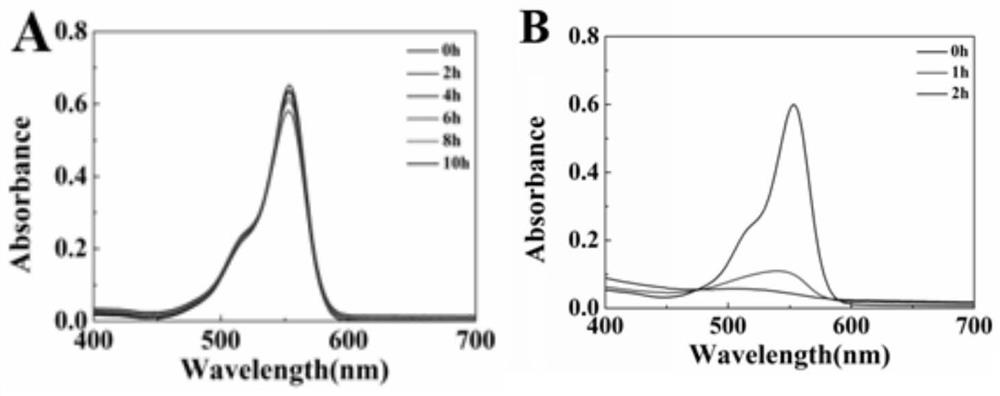

Image

Examples

Embodiment 1

[0023] A method for preparing a sunshade net with self-cleaning function, comprising the following steps:

[0024] 1) To prepare a composite titanium dioxide photocatalyst, add zinc chloride to ethylene glycol until the solid is completely dissolved to form a solution, add sodium citrate and sodium acetate to the solution until the solid is completely dissolved to form a mixed solution, ethylene glycol and chlorine The volume molar ratio of zinc chloride is 2L: 1mol; copper sulfate is dissolved in ethylene glycol to make a 6mol / L solution, and silver nitrate is dissolved in ethylene glycol to make a 6mol / L solution; Diol and ethylene glycol dissolved in silver nitrate were added to the mixture, stirred evenly, and finally tetrabutyl titanate was added, and the temperature was raised to 200°C in a closed reaction kettle for 12 hours. After the reaction was completed, it was cooled to room temperature, and the solid product was separated. , washed once with ethanol and distilled...

Embodiment 2

[0028] A method for preparing a sunshade net with self-cleaning function, comprising the following steps:

[0029] 1) To prepare a composite titanium dioxide photocatalyst, add zinc sulfate to ethylene glycol until the solid is completely dissolved to form a solution, add sodium citrate and sodium acetate to the solution until the solid is completely dissolved to form a mixed solution, ethylene glycol and zinc sulfate The volume molar ratio is 2L:1mol; Dissolve copper chloride in ethylene glycol to make a 6mol / L solution, and dissolve silver nitrate in ethylene glycol to make a 6mol / L solution; Diol and ethylene glycol dissolved in silver nitrate are added to the mixture, stirred evenly, and finally tetrabutyl titanate is added, and the temperature is raised to 150°C in a closed reaction kettle for 16 hours. After the reaction is completed, it is cooled to room temperature and the solid product is separated. , washed once with ethanol and distilled water, and calcined at 400°C...

Embodiment 3

[0033] A method for preparing a sunshade net with self-cleaning function, comprising the following steps:

[0034] 1) To prepare a composite titanium dioxide photocatalyst, add zinc nitrate to ethylene glycol until the solid is completely dissolved to form a solution, add sodium citrate and sodium acetate to the solution until the solid is completely dissolved to form a mixed solution, ethylene glycol and zinc nitrate The volume molar ratio is 2L: 1mol; Copper nitrate is dissolved in ethylene glycol to make a 6mol / L solution, and silver nitrate is dissolved in ethylene glycol to make a 6mol / L solution; Copper nitrate dissolved in ethylene glycol and Ethylene glycol dissolved with silver nitrate was added to the mixture, stirred evenly, and finally tetrabutyl titanate was added, and the temperature was raised to 250°C in a closed reaction kettle for 8 hours. After the reaction was completed, it was cooled to room temperature, and the solid product was separated. Wash once with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com