Preparation equipment and production process of diethylaluminium chloride mineral oil

A technology of diethylaluminum chloride and mineral oil, which is applied in the field of chemical production, can solve the problems of large motor power, consumption, and multiple power sources, and achieve the effects of reducing the use of power equipment, reducing production costs, and high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

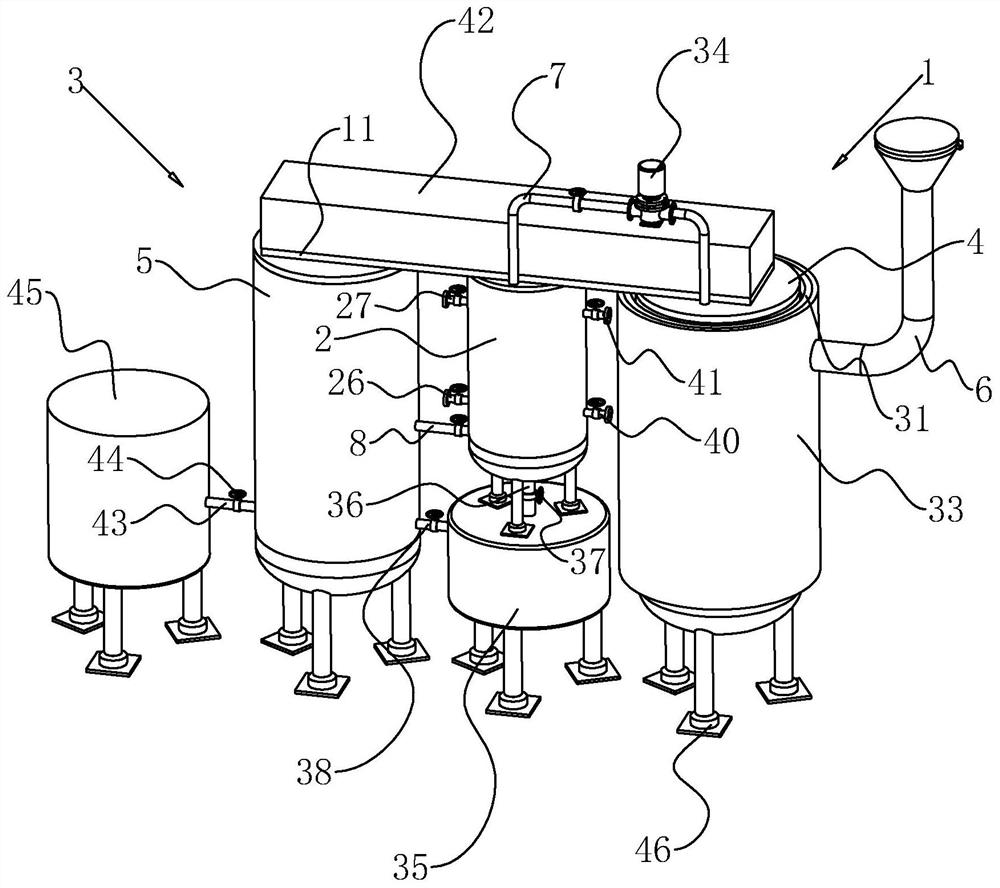

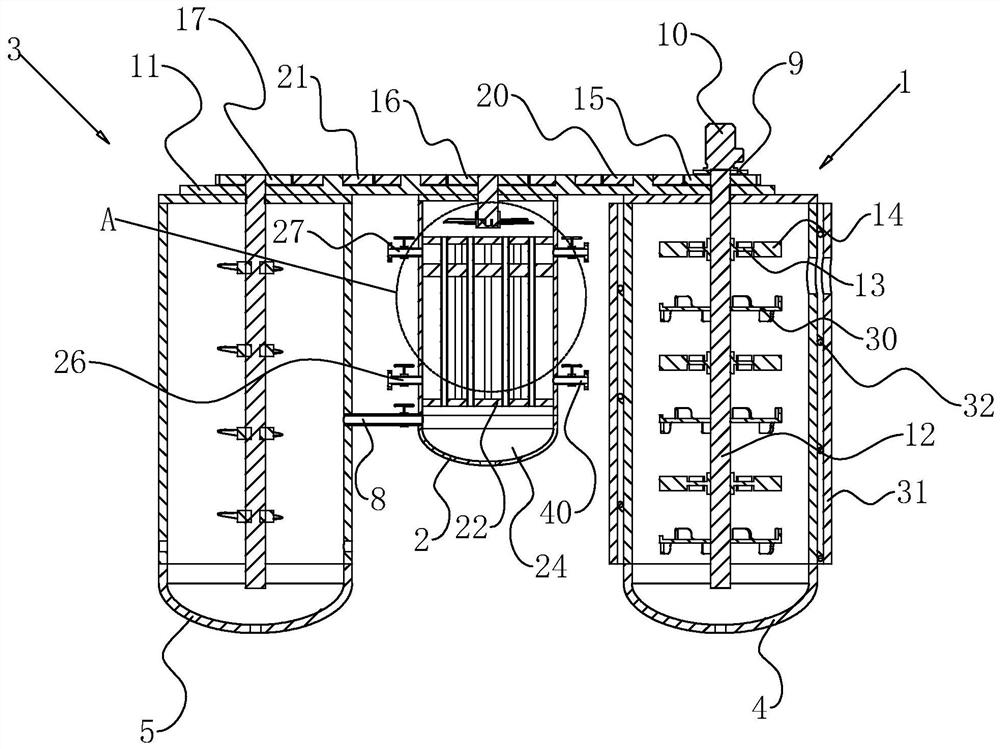

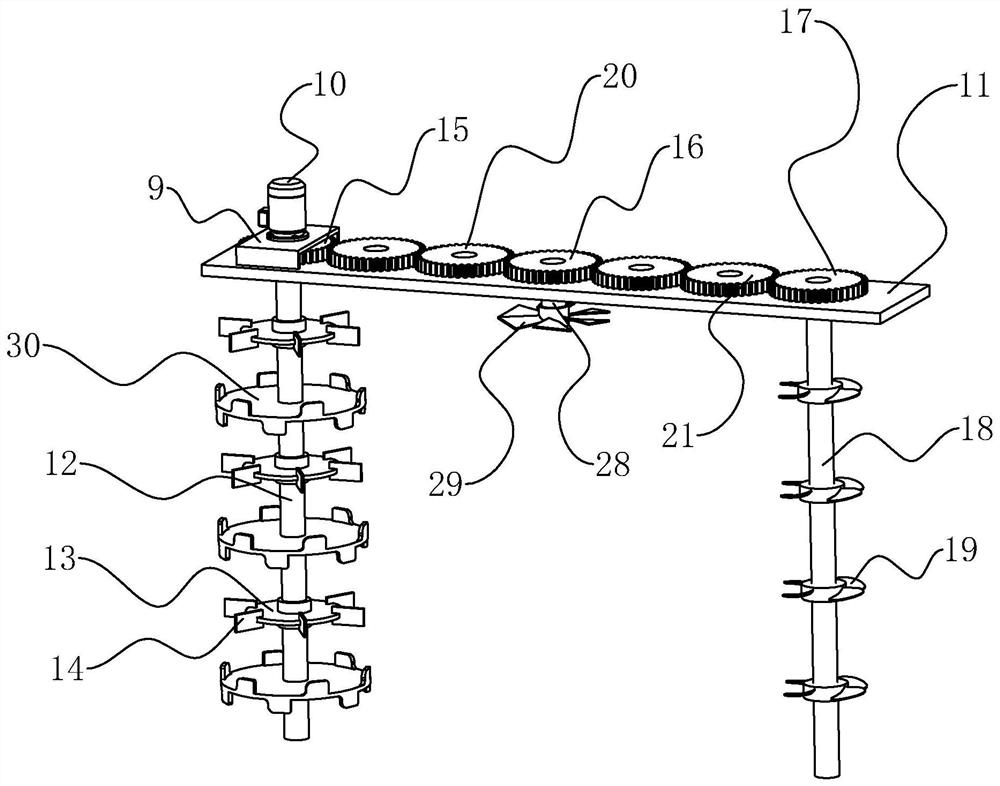

[0042] refer to figure 1 and figure 2 , a kind of preparation equipment of diethylaluminum chloride mineral oil, comprises reaction kettle 1, condensation tank 2 and preparation stirring tank 3, reaction kettle 1 comprises kettle body 4, preparation stirring tank 3 comprises tank body 5, kettle body 4 sides The wall is provided with a feeding pipe 6, and when the diethylaluminum chloride mineral oil solution is prepared, solid aluminum trichloride and liquid triethyldialuminum trichloride are added to the reaction kettle 1 from the feeding pipe 6. In the kettle body 4, a support frame 9 is fixedly connected above the kettle body 4, a motor 10 is fixedly installed on the upper end surface of the support frame 9, and the output shaft of the motor 10 passes through the strip plate 11 and the kettle body 4 is fixedly connected with a first stirring shaft 12 , the output shaft of the motor 10 is respectively connected to the strip plate 11 and the kettle body 4 in rotation, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com