Preparation method of diethyl aluminum hydride

A technology of diethylaluminum hydride and diethylaluminum chloride, applied in the field of preparation of alkylaluminum hydride, can solve the problems of low synthesis yield, expensive raw materials and unsuitable purchase, and achieves high purity, good use value, reduction strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific Embodiment 1: This embodiment provides a method for preparing diethylaluminum hydride. The following steps are all carried out under strict anhydrous and oxygen-free conditions. The specific steps are as follows:

[0022] (1) Add 100ml of Et to a 500ml three-neck round bottom flask 2 AlCl, slowly add 180ml of toluene under stirring condition, continue stirring for 30min;

[0023] (2) Slowly add 41g LiAlH when the temperature does not exceed 60°C 4 , after fully mixing, the oil bath controls the reaction temperature at 100°C for 4 hours;

[0024] (3) Cool to room temperature after the reaction, and then remove the solvent toluene by rotary evaporation at 55°C, and then filter to remove the gray solid substance;

[0025] (4) The filtrate was distilled under reduced pressure again, and the fraction was collected at 102°C to obtain a colorless transparent liquid.

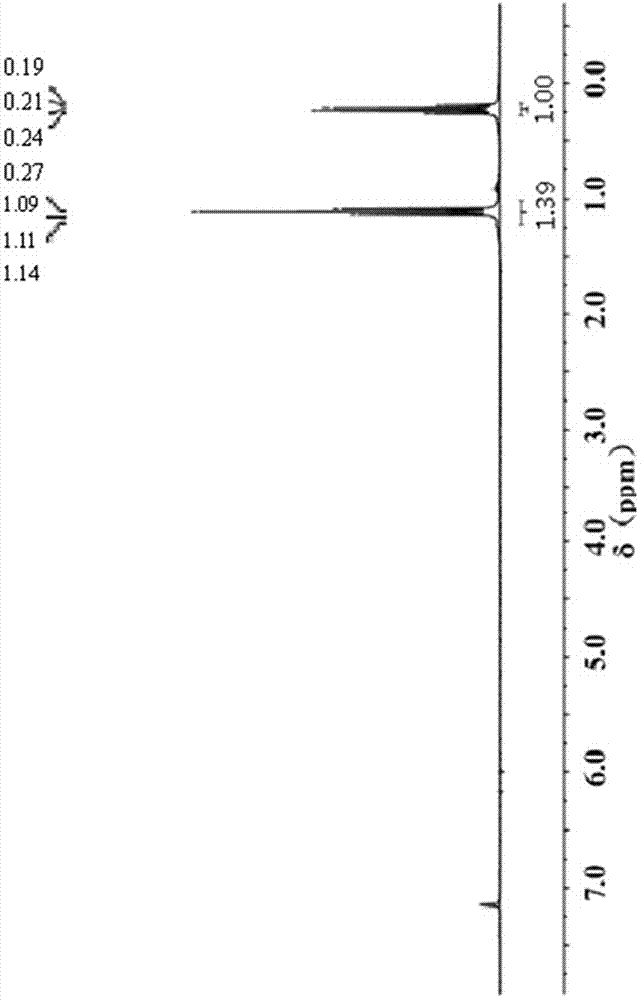

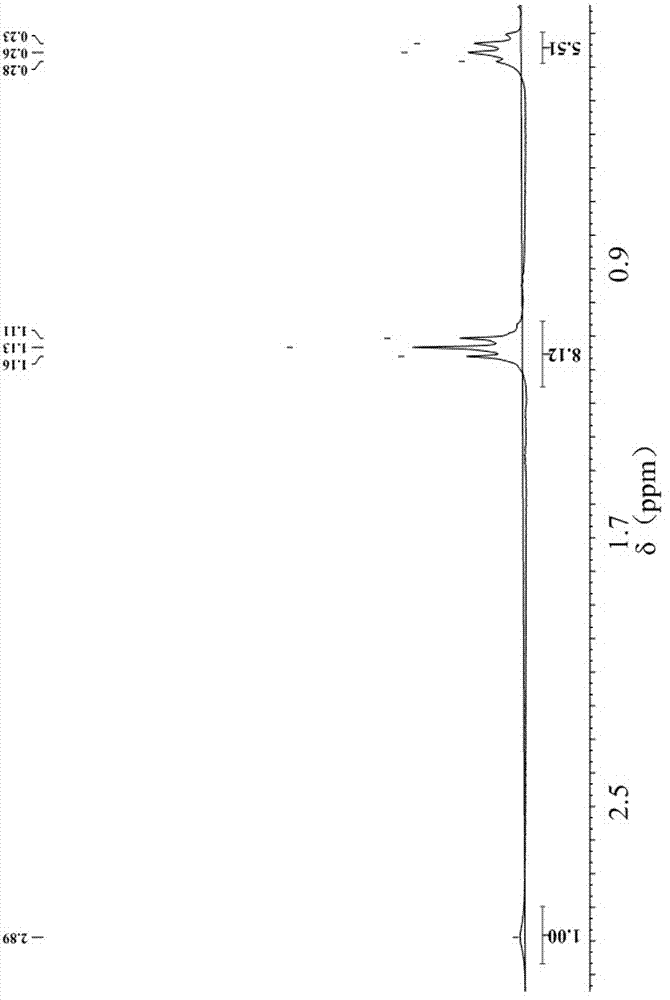

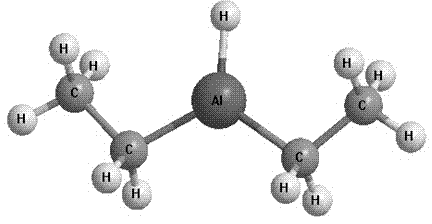

[0026] The raw material Et2AlCl used in the present embodiment 1 H NMR as figure 1 As shown, the...

specific Embodiment approach 2

[0027] Specific embodiment two: This embodiment provides a method for preparing diethylaluminum hydride, the following steps are all carried out under anaerobic conditions, and the specific steps are as follows:

[0028] (1) Add 100ml of Et to a 500ml three-neck round bottom flask 2 AlCl, slowly add 180ml of benzene under stirring condition, continue stirring for 30min;

[0029] (2) Slowly add 41g LiAlH when the temperature does not exceed 60°C 4 , after fully mixing, the oil bath controls the reaction temperature at 100°C for 4 hours;

[0030] (3) After the reaction is completed, cool to room temperature, then distill off the solvent under reduced pressure at 55°C, and then filter to remove the gray solid substance;

[0031] (4) The filtrate was distilled under reduced pressure again, and the fraction was collected at 102°C to obtain a colorless transparent liquid.

[0032] Raw material Et used in this embodiment 2 AlCl 1 H NMR as figure 1 As shown, the prepared Et 2 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com