Cycloolefin copolymer and preparation method thereof

A cycloolefin copolymer and copolymer technology, which is applied in the field of olefin polymerization, can solve the problems affecting the transparency of polymers and the heat resistance performance needs to be improved, and achieve the effect of improving transparency, good tolerance, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] In the preparation process of the cyclic olefin copolymer of the present application, norbornene and tetracyclododecene are simple in structure, easy to synthesize, and have high reactivity, and the obtained ethylene / norbornene copolymer or ethylene / tetracyclododecene copolymer Regular structure and excellent performance.

[0023] In one embodiment, the cocatalyst is an alkylaluminoxane with a structure of (-AlM-O-)n, where n is any positive integer.

[0024] Preferably, the M is any one of methyl, ethyl, isobutyl and n-octyl; more preferably, the M is methyl or isobutyl.

[0025] In the preparation process of the cycloolefin copolymer of the present application, when M is methyl or isobutyl, the synergistic effect with the catalyst is better.

[0026] In one embodiment, the raw materials for the preparation of the cycloolefin copolymer further include an inert hydrocarbon solvent.

[0027] Preferably, the inert hydrocarbon solvent is an alkane and / or an aromatic hydr...

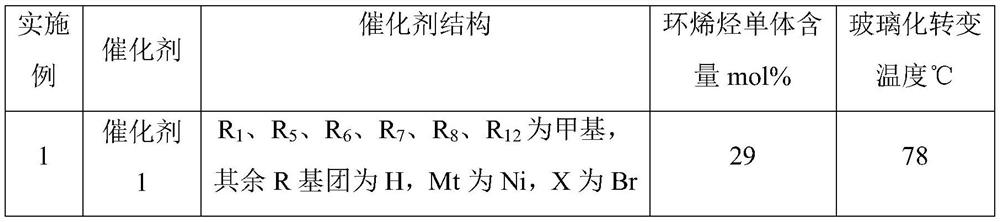

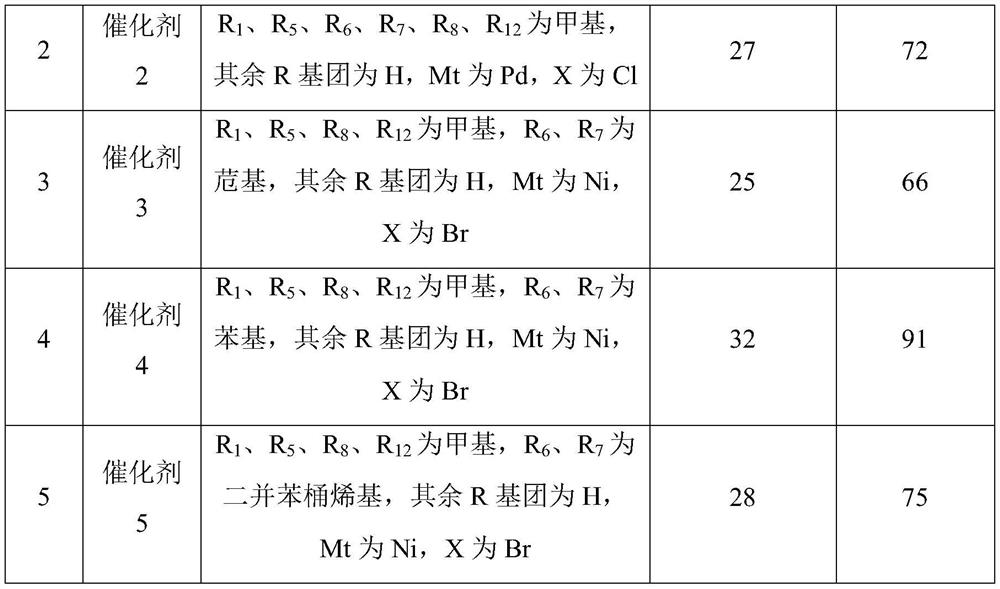

Embodiment 1

[0041] Embodiment 1 of the present invention provides a kind of described cyclic olefin copolymer, and its preparation method is as follows:

[0042] Under nitrogen atmosphere, add 38mL pre-prepared 0.30mol / L norbornene toluene solution, 1mL 10wt% methylaluminoxane toluene solution (cocatalyst) to the 100mL glass bottle, adjust the ethylene pressure to 1atm, Stir and balance at 20°C for 30 minutes; then add 1 mL of 1 μmol / mL catalyst 1 toluene solution to start the reaction, keep the ethylene pressure at 1 atm, and carry out the polymerization reaction for 30 minutes; add the reaction solution to 10vol% hydrochloric acid / ethanol solution to terminate the reaction, filter The precipitated copolymer was washed with ethanol, and vacuum-dried at 80° C. for 24 hours to obtain 0.55 g of a copolymer.

[0043] The structure of the catalyst 1 is R in Catalyst 1 1 -R 12 , Mt and the physical properties of the copolymer are described in Table 1 below.

Embodiment 2

[0045] Example 2 of the present invention provides the cyclic olefin copolymer. The specific implementation of the preparation method is the same as that of Example 1, except that Catalyst 2 is used instead of Catalyst 1 to obtain a copolymer with a weight of 0.52 g.

[0046] The structure of the catalyst 2 is R in Catalyst 2 1 -R 12 , Mt and the physical properties of the copolymer are described in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com