Circular-ring-shaped groove even oil supplying structure vertically provided with rolling bearings

A technology of rolling bearings and circular rings, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., which can solve the problems of poor cooling and lubrication effect of the raceway and inability to achieve cooling and lubrication effects, and achieve uniform cooling and The effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

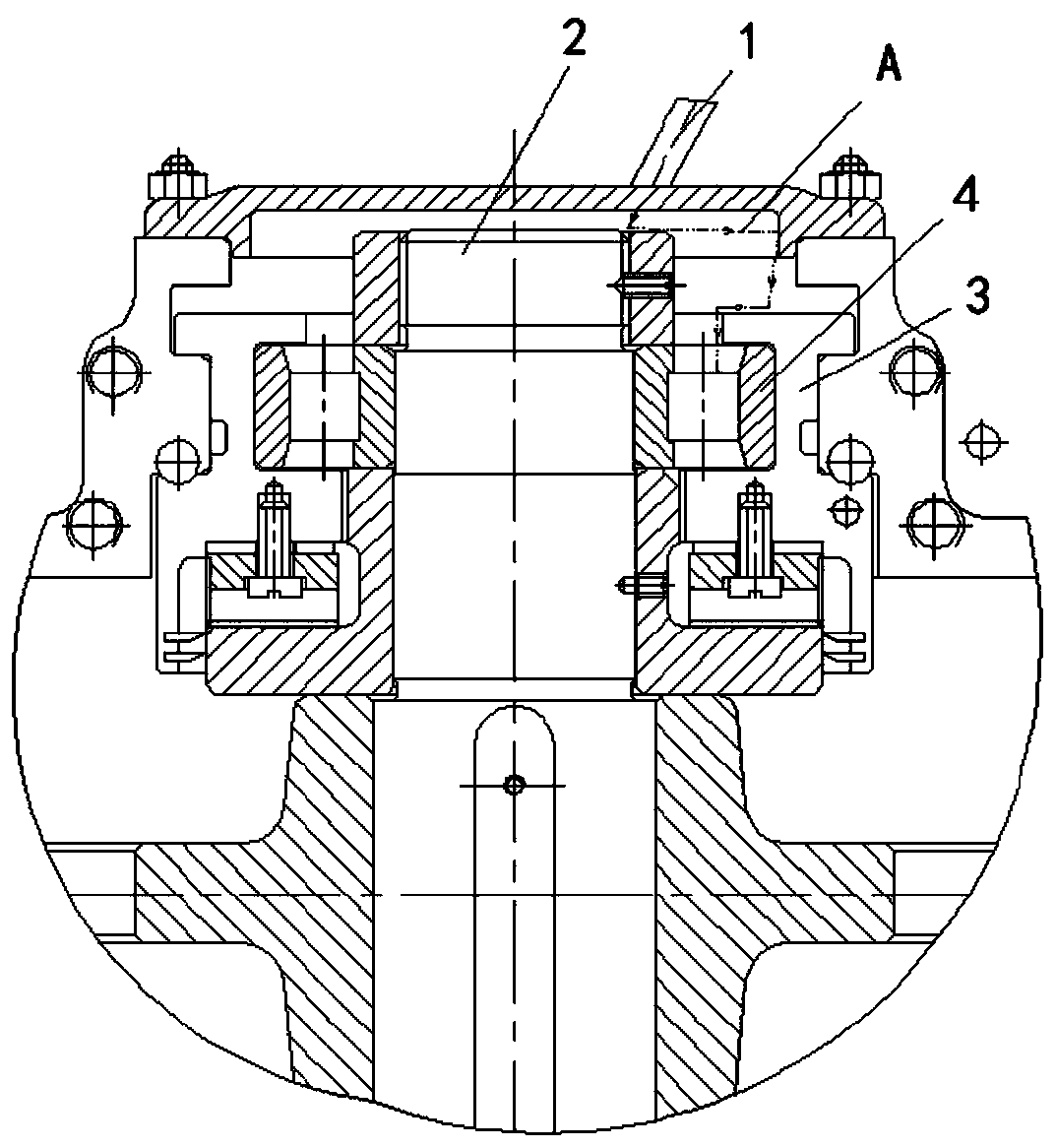

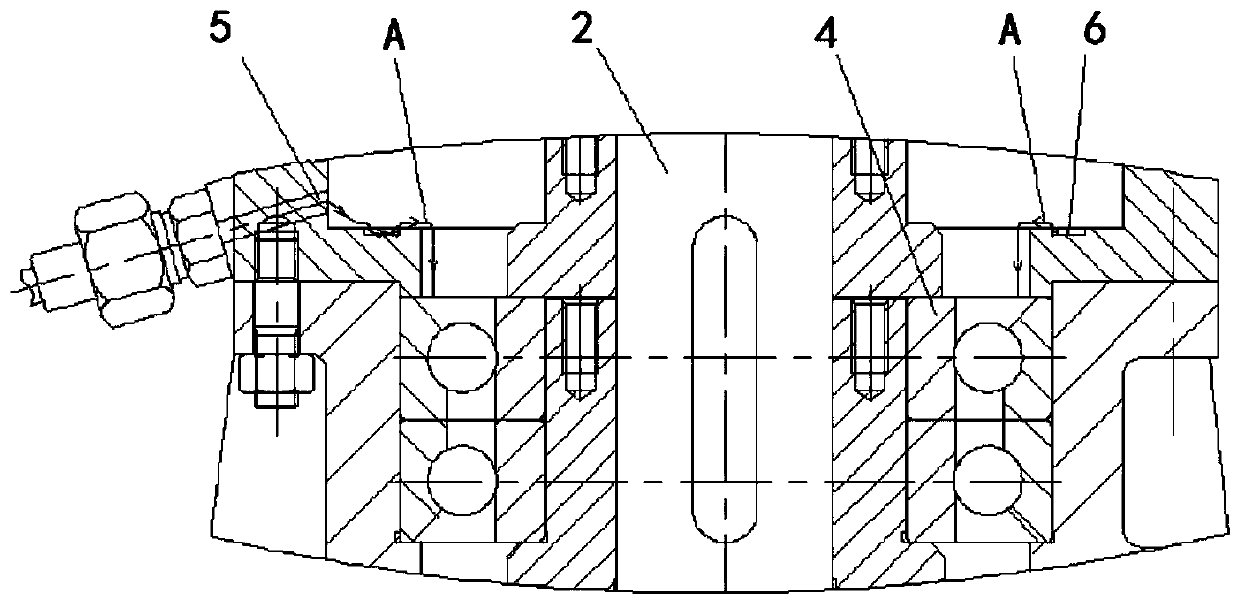

[0015] As shown in 2, a circular groove uniform oil supply structure for vertically installed rolling bearings, that is, a circular groove structure 6 is opened on the stationary part above the rolling bearing 4 and below the oil supply port 5, and from the oil supply port The lubricating oil coming out of 5 first fills the annular groove structure 6, and overflows onto the rolling bearing 4, so as to realize more uniform cooling and lubrication of the entire raceway.

Embodiment 2

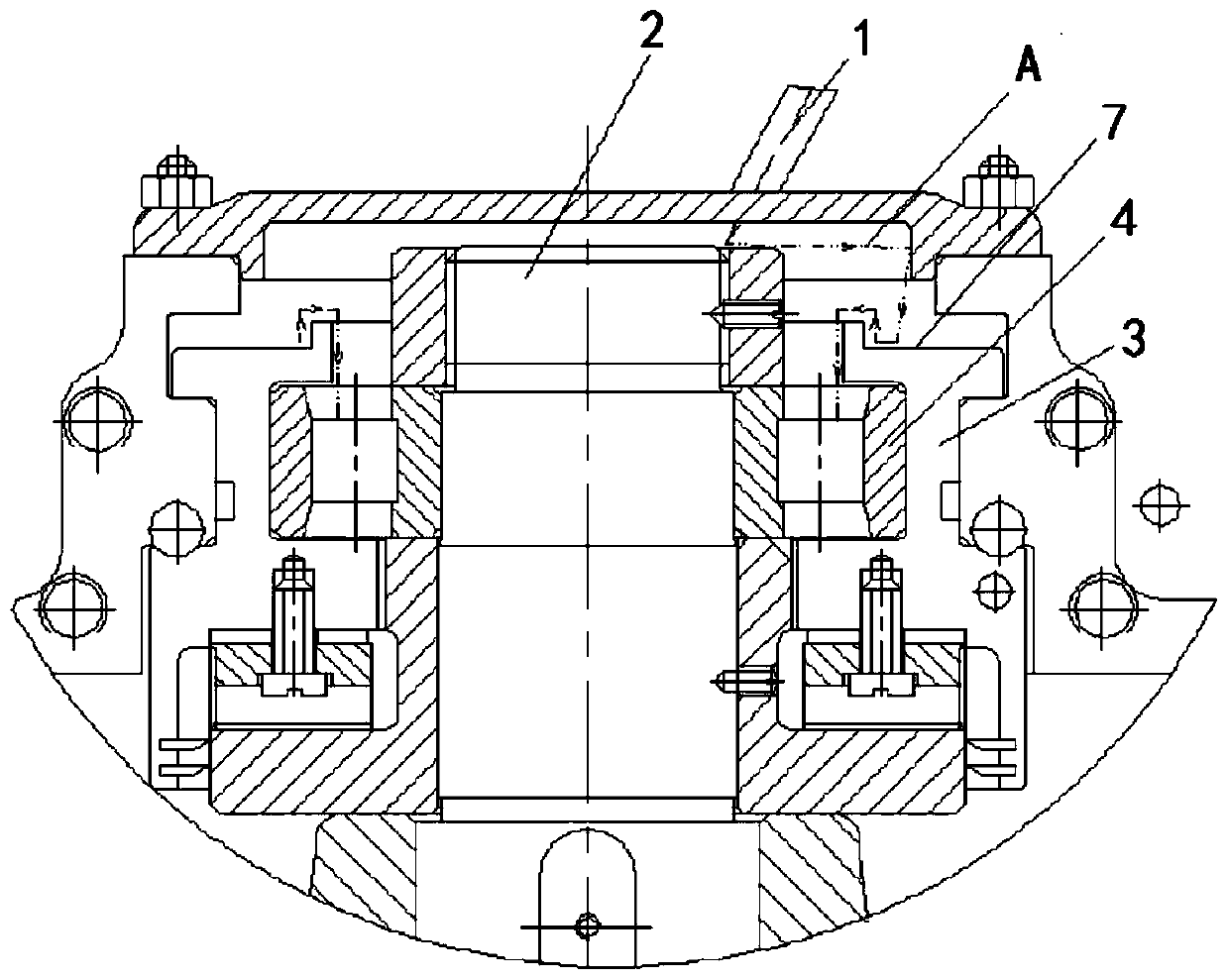

[0017] like image 3 As shown, a vertically installed rolling bearing has a circular groove uniform oil supply structure, that is, a circular concave structure 7 is processed on the upper end of the bearing housing 3, and the lubricating oil coming out of the oil supply pipe 1 first fills the circular ring Concave structure 7, and overflow to the rolling bearing 4, to achieve more uniform cooling and lubrication of the entire raceway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com