Self-lubricating mechanical seal

A mechanical seal, self-lubricating technology, applied in the direction of engine sealing, mechanical equipment, engine lubrication, etc., can solve problems such as spending a lot of time, easy wear of contact surfaces, damage to mechanical seals, etc., to achieve uniform lubrication effect and protect contact. surface, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

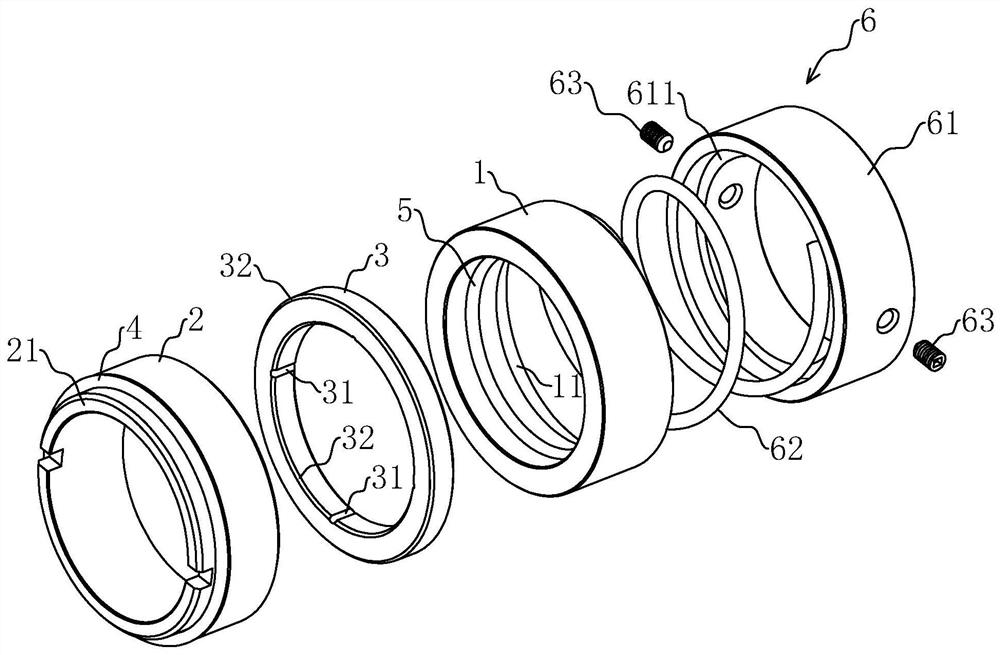

[0032] The following is attached figure 1 The application is described in further detail.

[0033] The embodiment of the present application discloses a self-lubricating mechanical seal. refer to figure 1 , The self-lubricating mechanical seal includes a moving ring 1, a static ring 2, a self-lubricating ring 3, a first sealing ring 4, a second sealing ring 5 and an elastic compression member 6.

[0034] The inner and outer diameters of the moving ring 1, the static ring 2, and the self-lubricating ring 3 are the same, and when the self-lubricating mechanical seal is working, the moving ring 1, the static ring 2, the self-lubricating ring 3 and the elastic pressing member 6 are all worn On a rotating shaft, the moving ring 1 is fixed on the main body of the equipment. The materials of the moving ring 1 and the static ring 2 are one of the following materials: hard alloy, alloy steel, high chromium iron, silicon carbide, aluminum oxide, oxide Materials such as zirconium or b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com