Telescopic shaft

一种伸缩轴、螺纹轴的技术,应用在伸缩轴领域,能够解决耐久性问题等问题,达到提高耐久性、减少和变形、顺畅润滑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

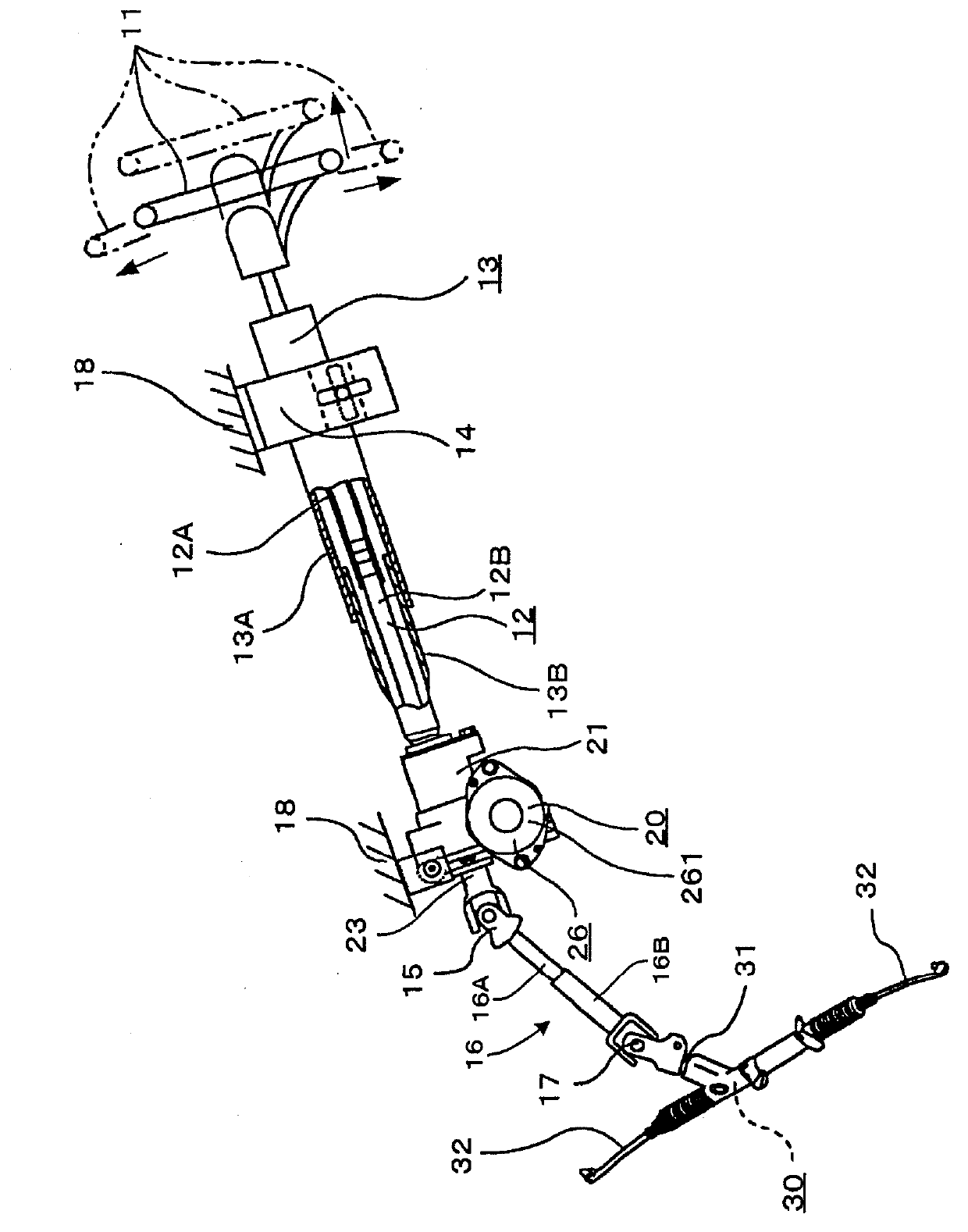

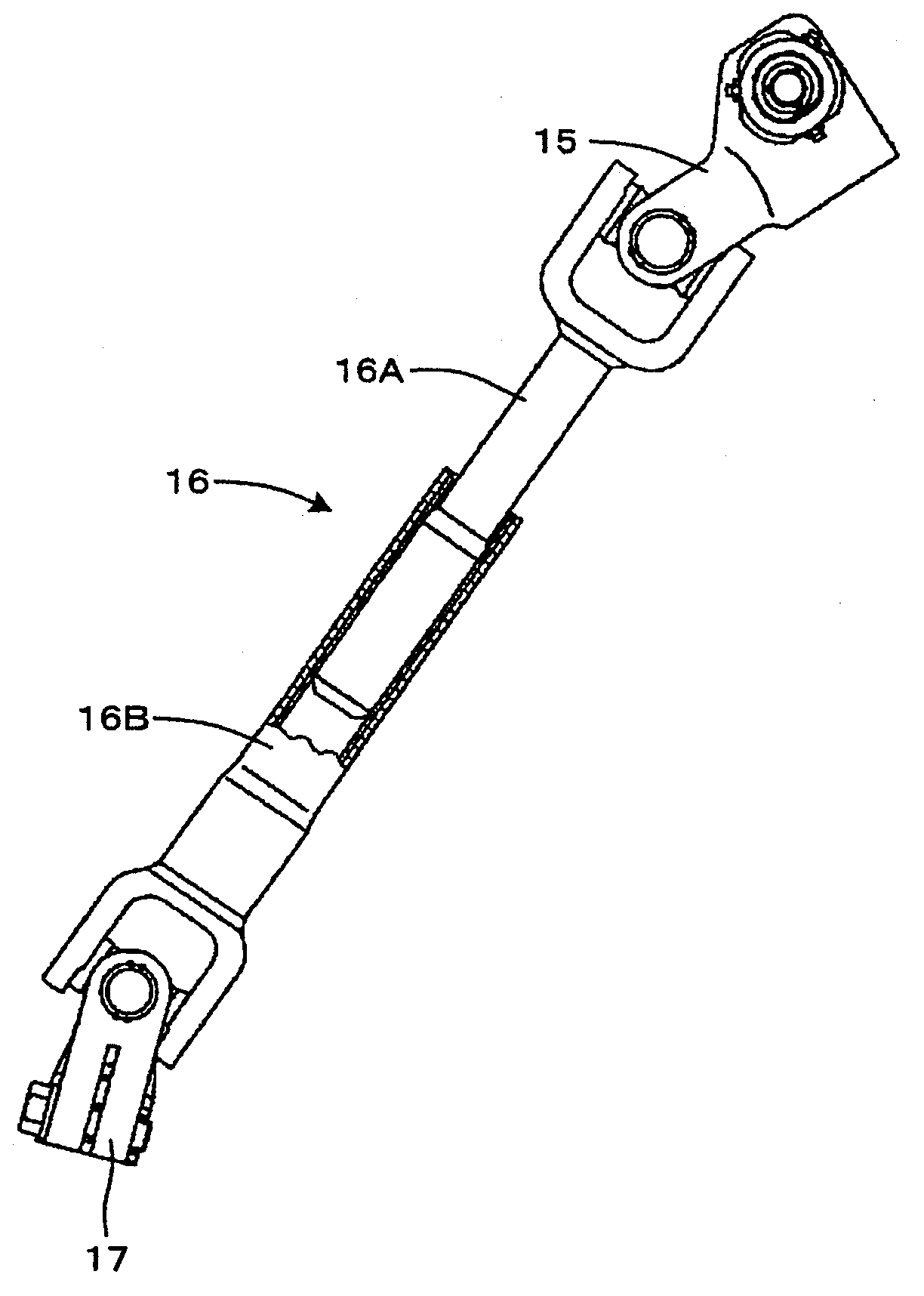

[0049] Below, refer to Figure 1 ~ Figure 4 Example 1 of the present invention will be described.

[0050] like figure 1 As shown, the steering device of an embodiment of the present invention has: figure 1 The right side in the middle) the steering shaft 12 of the steering wheel 11 is installed; the steering column 13 through which the steering shaft 12 is inserted; Body front side ( figure 1 The left side in ) the steering gear 30 connected via a rack and pinion structure not shown.

[0051] The steering shaft 12 has an outer shaft 12A and an inner shaft 12B. The outer shaft 12A and the inner shaft 12B are combined so that torque can be freely transmitted and relative displacement in the axial direction is possible. That is, a plurality of externally threaded splines are formed on the outer periphery of the inner shaft 12B on the vehicle body rear side. On the inner periphery of the outer shaft 12A on the vehicle body front side, a plurality of female splines are forme...

Embodiment 2

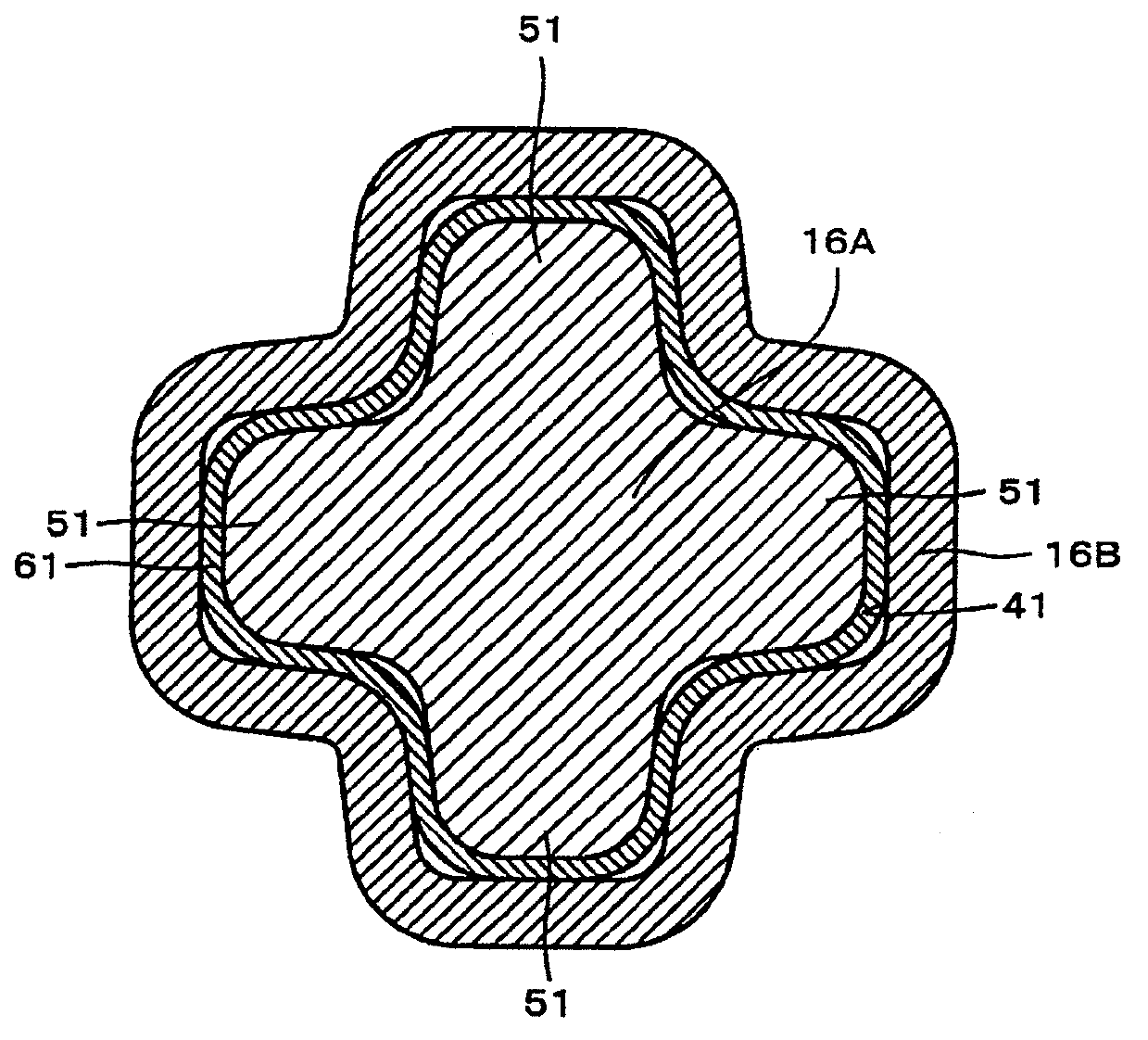

[0070] Next, refer to Figure 6 Example 2 of the present invention will be described. Hereinafter, features different from those of Embodiment 1 will be mainly described, and redundant descriptions will be omitted. Example 2 is an example in which a relief portion is formed at the dedendum of the covering portion 61 of the protruding tooth 51 .

[0071] like Figure 6 As shown, the telescopic shaft of the second embodiment is the same as that of the first embodiment, and the tooth surface 511 of the protruding tooth 51 of the externally threaded shaft 16A is covered with the covering part 61 . The tooth surface 611 of the covering portion 61 of the protruding tooth 51 protrudes in an arc shape outward in the radial direction of the male thread shaft 16A. The curvature radius R1 of the tooth surface 611 is smaller than the curvature radius R2 of the tooth surface 411 of the tooth groove 41 . In addition, R chamfers (chamfers) 612 and 613 protruding outward in the radial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com