Automatic oiling system of turnout

A technology of automatic oil injection and turnout, which is applied in the direction of roads, tracks, buildings, etc., can solve the problems of increasing the movement resistance of the outer locking device, increasing the maintenance workload of on-site operators, and insufficient lubrication of the outer locking device, so as to improve the utilization rate and Use stability, good lubrication, uniform lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

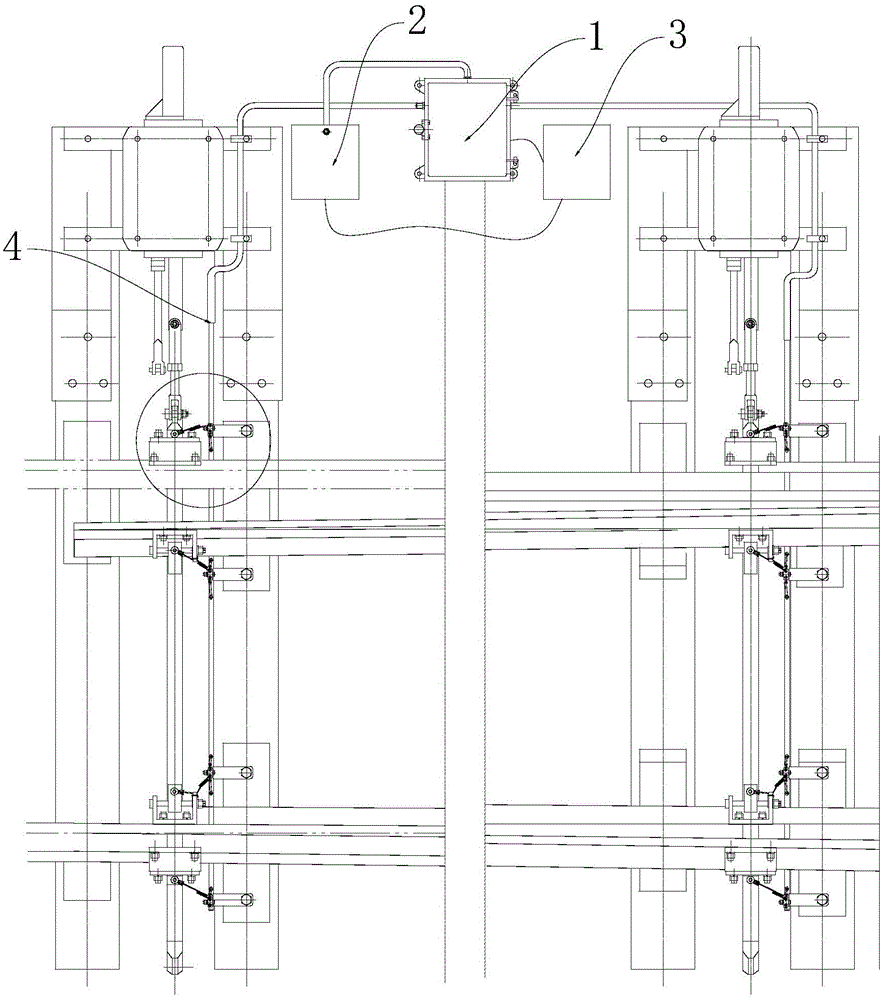

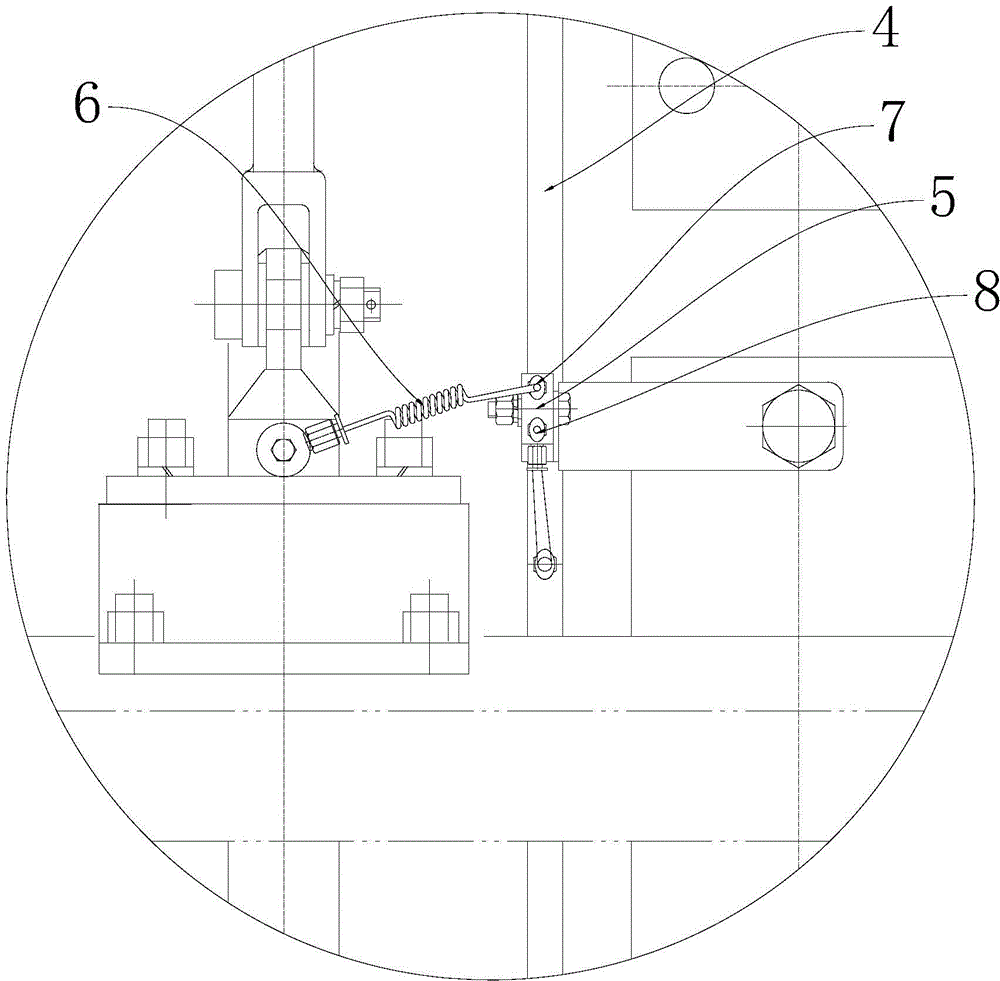

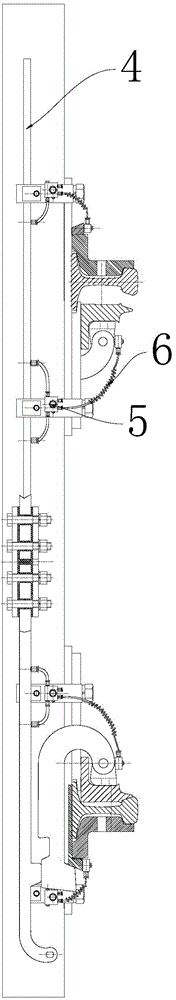

[0018] Such as figure 1 , figure 2 , image 3 As shown, the turnout automatic oiling system described in this embodiment includes an oiling machine 1, a controller 2 and a power supply mechanism 3, the power supply mechanism 3 is connected to the oiling machine 1, and the oiling machine 1 is connected to the controller 2 at the same time. An oil supply pipe 4 is connected to the oil injection machine 1, and the oil supply pipe 4 is connected to the first traction point, the second traction point and the third traction point of the switch. Oil separators 5 are provided on both sides of the traction point, and the oil separators 5 and oil supply pipes 4 are connected to each other. The oil separators 5 are connected to the lock hooks, locking irons, and locking rods of the turnout through the oil delivery pipes 6. , the oil inlet pipe and the oil return pipe of the oil separator 5 are all connected with the oil supply pipe 4, the oil injection machine 1 is a microcomputer pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com