Direct-drive wind turbine

A wind turbine, driven technology, applied in the direction of wind turbines, wind turbine components, engines, etc., can solve the problems of large pads, heavy pads, difficult to replace, etc., to achieve energy saving, bearing manufacturing more efficient, and optimize wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

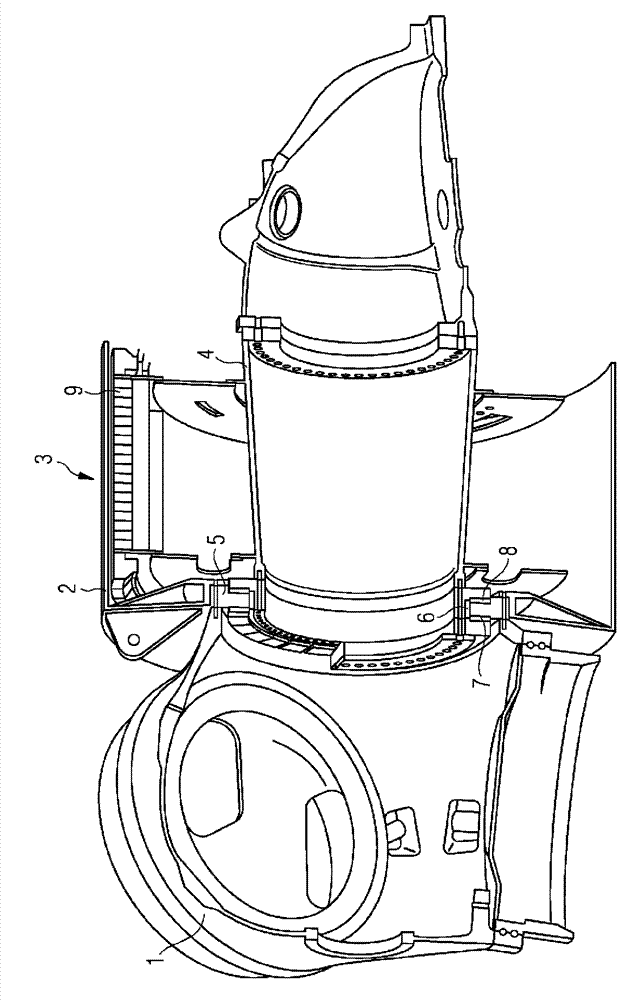

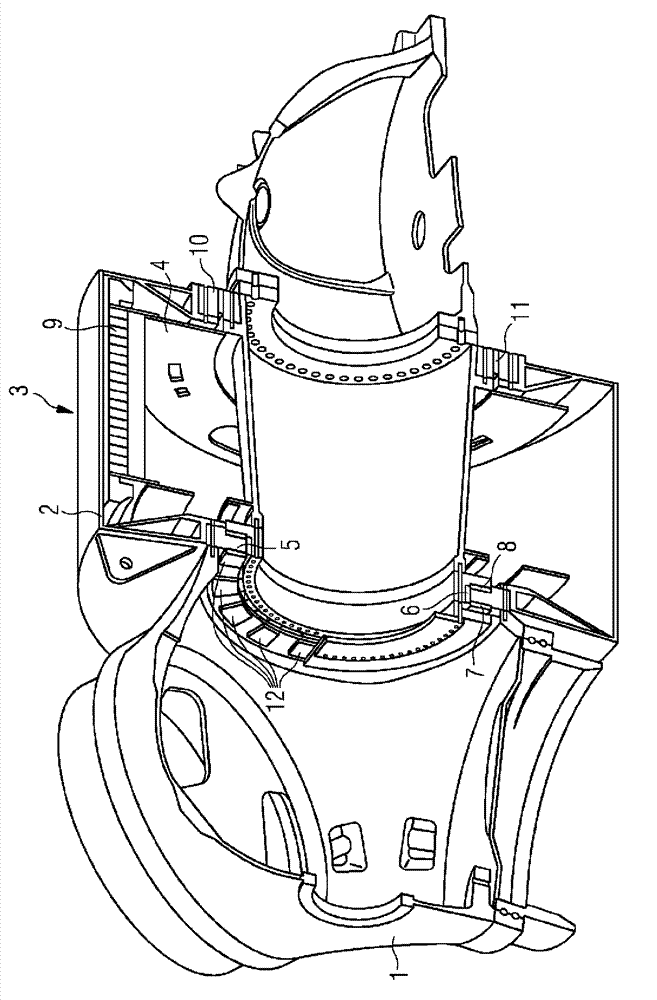

[0068] figure 1 A longitudinal section through the hub 1 , plain bearing 5 and generator 3 of a direct drive wind turbine is shown. The longitudinal section is taken along the axis of rotation of the generator 3 of the wind turbine.

[0069] The hub 1 is connected to the rotor 2 of the generator and to the rotating side of the bearing 5 . The stator 9 of the generator 3 and the fixed side 4 of the wind turbine are connected to the fixed side of the slide bearing 5 .

[0070] A plain bearing 5 is located between the hub 1 of the wind turbine and the generator 3 of the wind turbine. It is connected with the fixed side to the hub-side end of the stator 9 of the generator 3 and with the rotating side to the hub 1 of the wind turbine.

[0071] The plain bearing 5 rotatably connects the rotating drive train of the wind turbine with the stator 9 of the generator and the stationary part 4 of the wind turbine.

[0072] The rotating drive train comprises a hub 1 of the wind turbine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com