Rotationally lubricating type sealing brake cylinder for railway vehicles

A technology for railway vehicles and brake cylinders, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve problems such as dry wear and damage, achieve small transformation workload, simple structure, and avoid poor mitigation or leakage faults Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

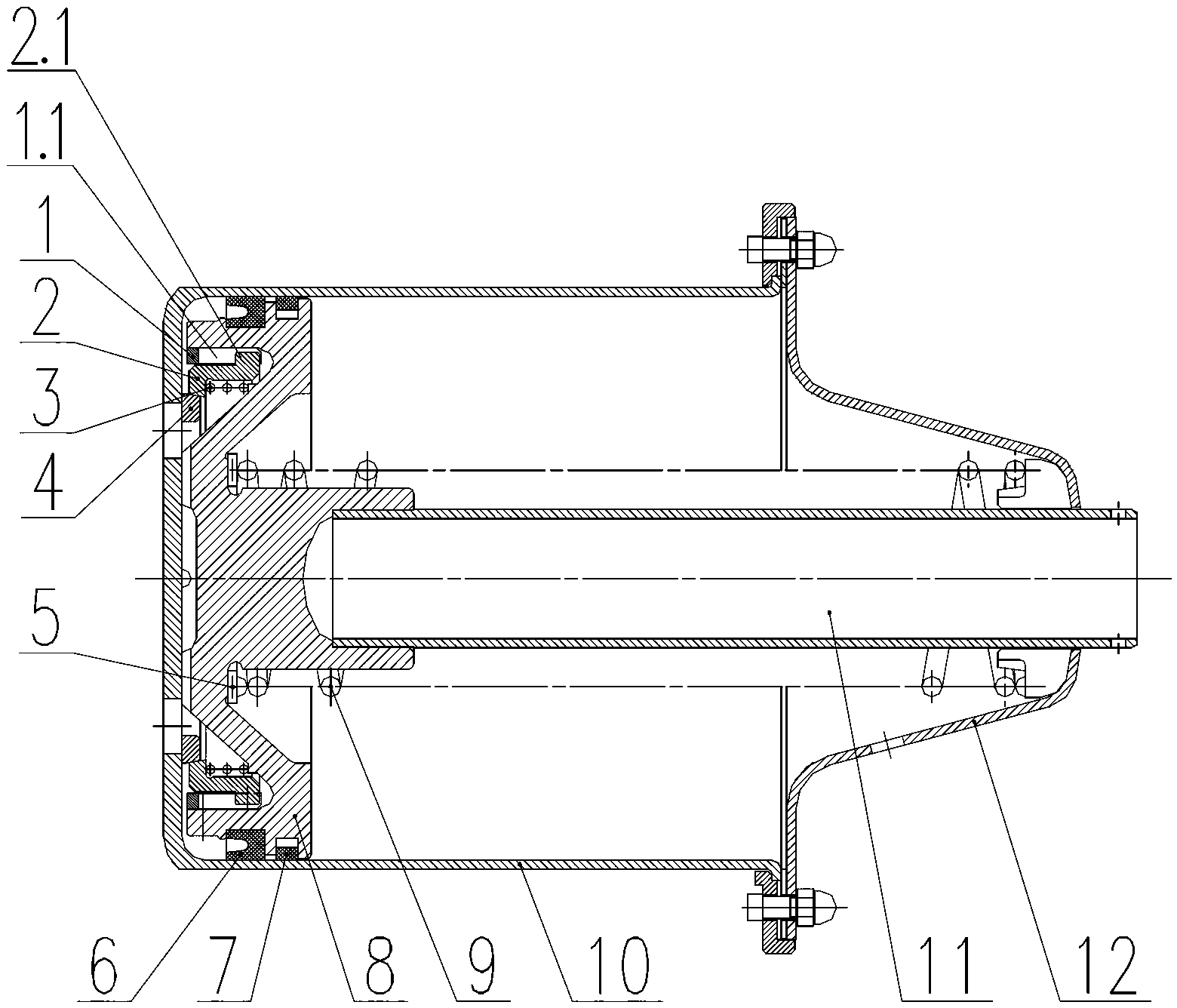

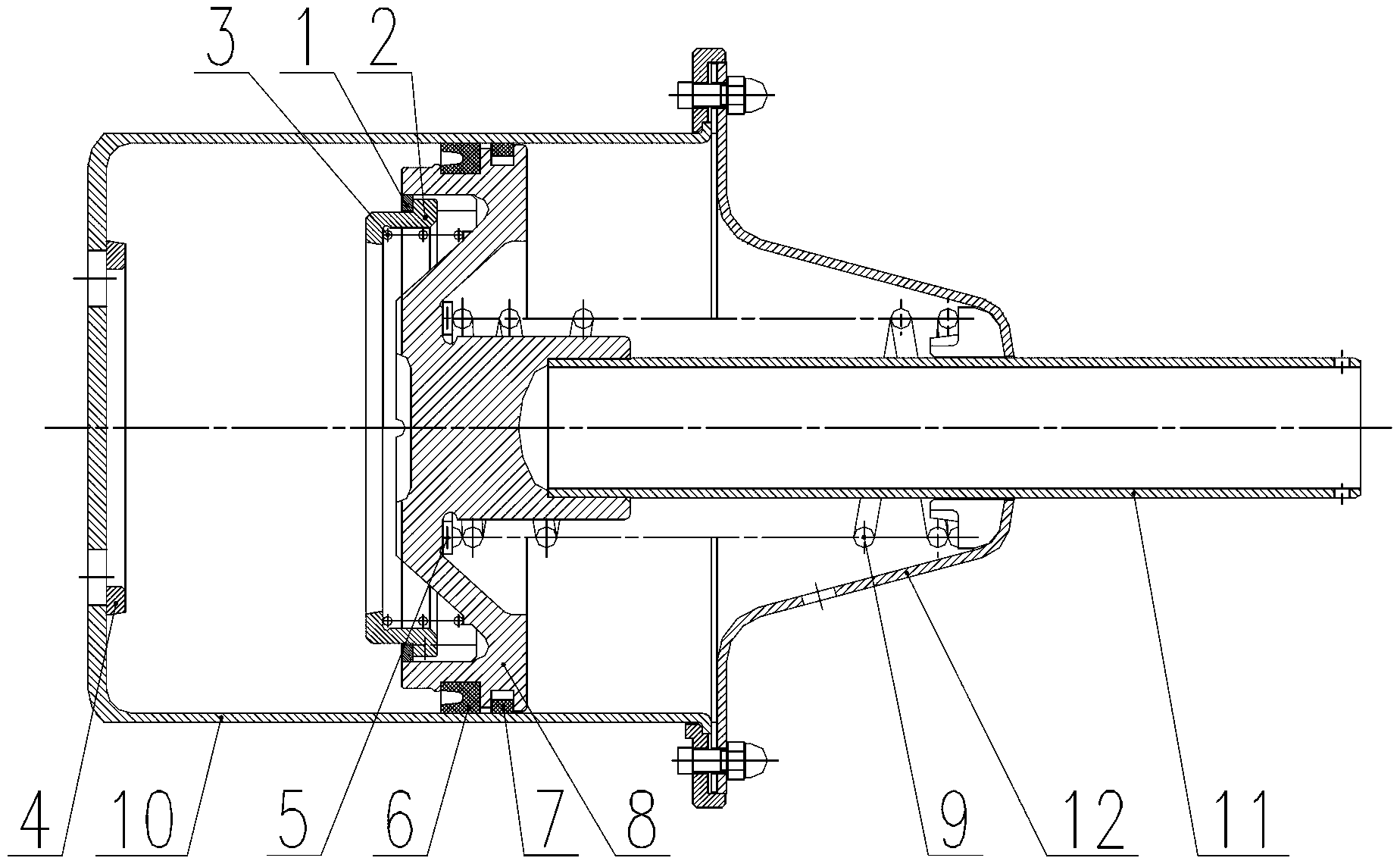

[0027] Such as Figure 1~5 As shown, the railway vehicle rotary lubricating sealed brake cylinder of the present invention comprises a cylinder block 10 and a front cover composition 12, a piston 8 and a piston rod 11 are arranged in the cylinder block 10, and a sealing ring 6 and a lubricating sleeve are arranged on the outer wall of the piston 8 7. A relief spring 9 is arranged between the bottom of the piston 8 and the front cover assembly 12, and the piston rod 11 extends out of the front cover assembly 12.

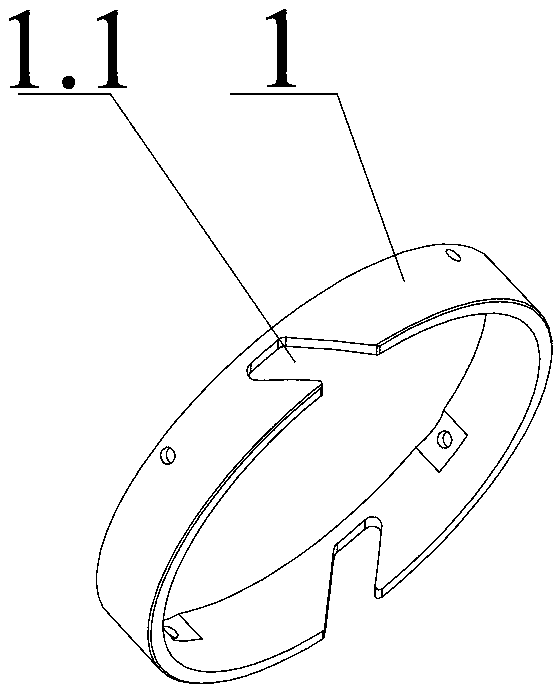

[0028] A guide ring 1 is fixed on the inner wall of the ring groove at the top of the piston 8 by a rivet, and a guide sleeve 2 is arranged inside the guide ring 1 . Specifically, there are two guide chute 1.1 symmetrically arranged on the ring wall of the guide ring 1, and the inclination angle of the two guide chute 1.1 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com