Low temperature atomization lubrication cooling system

An atomization lubrication and cooling system technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of inability to reduce the cutting heat of the tool, burning the tool and overheating the workpiece, large lubricating oil particles, etc. problem, to achieve the effect of strong cooling performance, uniform lubrication, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

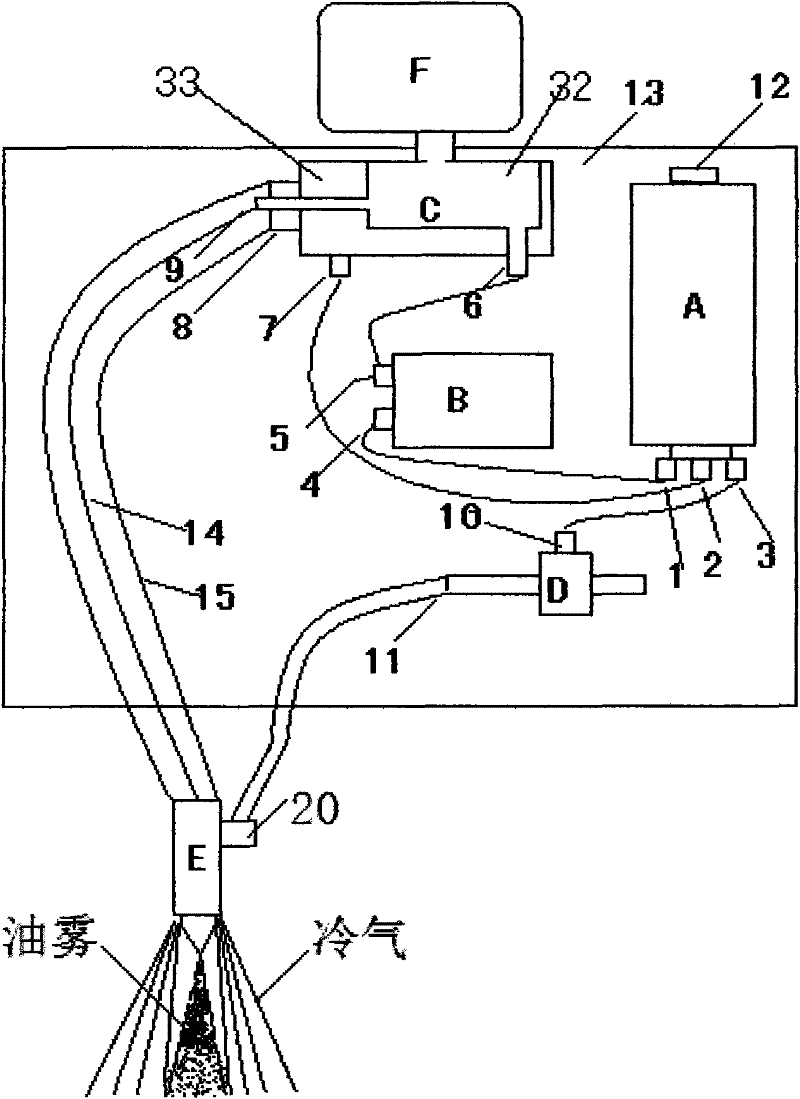

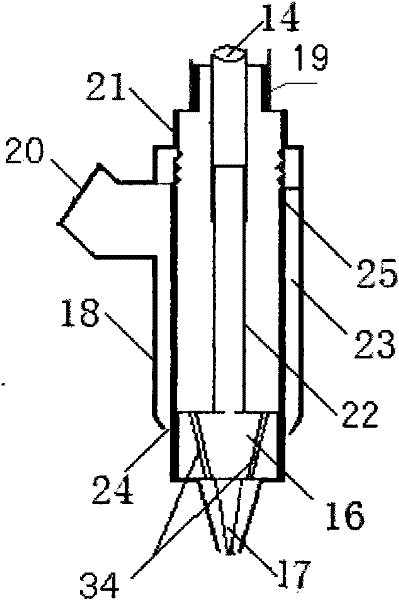

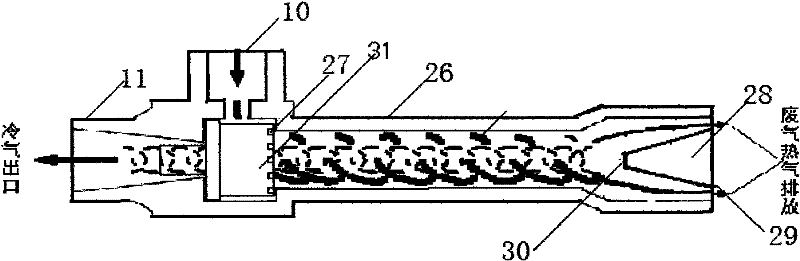

[0014] refer to figure 1 . In the low-temperature atomization lubrication cooling system provided by the present invention, there is an installation box 13 . The lubricating oil cup F is fixedly connected above the installation box 13 . The lubricating oil cup F is connected to the shunt pump C arranged in the box body 13 through a communication joint. The supercharger A connected with the compressed air source is fixedly connected to one side of the installation box 13 . The external compressed air source enters the supercharger A through the compressed air source inlet 12 connected to the upper end of the supercharger A. Between the supercharger A and the liquid-feeding lubricating oil cup F, a shunt pump C communicated through the supercharger A is provided. The supercharger A communicates with the rectifying atomizing nozzle E through the split flow pump C, and communicates with the oil cup F and the pulser B at the same time. Below the supercharger A, three-component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com