Method for measuring niobium content in iron ore

An iron ore and content technology, which is applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

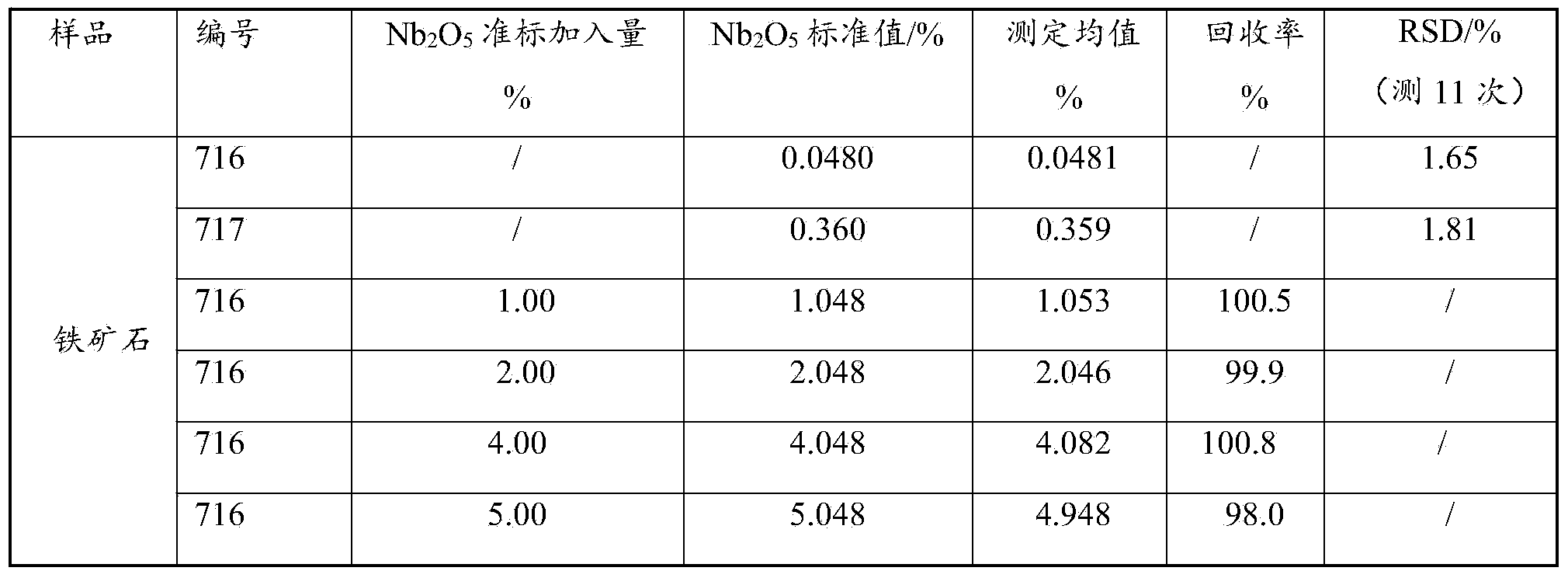

[0021] The invention is an ICP-AES (inductively coupled plasma emission spectrometry) method for measuring the amount of niobium in iron ore, which can quickly measure the amount of niobium in the ore, not only has high sensitivity, low detection limit, fast measurement speed, and easy operation It is simple and has less interference than other methods, and has practical promotion significance.

[0022] Step 1: take the iron ore sample and melt it through the mixed flux (1.4);

[0023] Step 2: Leach with tartaric acid and hydrochloric acid at low temperature and set the volume to a certain volume, shake the liquid to be tested;

[0024] Step 3: use the niobium standard solution, select the same acid medium, prepare at least four working curve standard solutions for the determination of niobium content in a volumetric flask, and the niobium content of the test solution falls within the range of the working curve;

[0025] Step 4: On the inductively coupled plasma emission spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com