A kind of preparation method of degradable polybutylene adipate/potassium bromide composite material

A technology of polybutylene adipate and composite materials, which is applied in the field of preparation of polybutylene adipate/potassium bromide composite materials, can solve problems such as hindering application, slow crystallization speed, and poor hardness. Achieve excellent biocompatibility, excellent biodegradability, and improve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

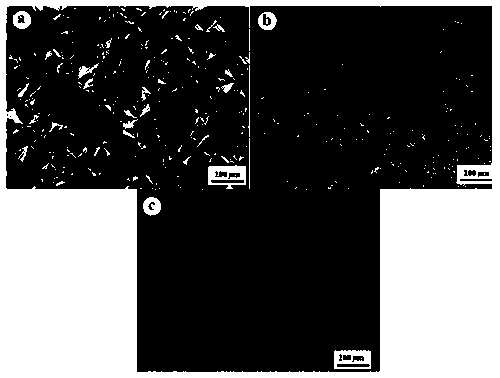

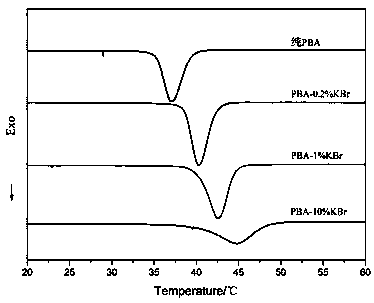

[0025] A preparation method of a degradable polybutylene adipate / potassium bromide composite material is characterized in that it comprises the following steps:

[0026] 1) Grind the potassium bromide particles for 2 hours and dry them in vacuum at 150°C for 1 week for use;

[0027] 2) Weigh PBA=0.2g, put it in a 10ml volumetric flask, use PBA's good solvent CHCl 3 Dilute the volume to 10ml, add a magnetic stirring rotor and magnetic stirring at room temperature for 30 minutes to completely dissolve the PBA, in triplicate;

[0028] 3) Weigh 0.002g and 0.02g of KBr described in step 1) and add them to the PBA solution obtained in step 2) to obtain three blended solutions with KBr content of 0 wt%, 1 wt% and 10 wt% respectively;

[0029] 4) Add 0.1ml of deionized water to the PBA solution with different content of KBr obtained in step 3), and then move the volumetric flask into the KQ3200E ultrasonic instrument with normal temperature ultrasound for 1 hour to prepare PBA / KBr suspension c...

Embodiment 2

[0035] A degradable polybutylene adipate / potassium bromide composite material and a preparation method thereof, characterized in that it comprises the following steps:

[0036] 1) Grind the potassium bromide particles for 2 hours and dry them in vacuum at 150°C for 1 week for use;

[0037] 2) Weigh PBA=0.2g, put it in a 10ml volumetric flask, use PBA's good solvent CHCl 3 Dilute the volume to 10ml, add a magnetic stirring rotor and magnetic stirring at room temperature for 30 minutes to completely dissolve the PBA, in triplicate;

[0038] 3) Weigh 0.002g and 0.02g of KBr described in step 1) and add them to the PBA solution obtained in step 2) to obtain three blended solutions with KBr content of 0wt%, 1wt% and 10wt% respectively;

[0039] 4) Add 0.2ml of deionized water to the PBA solution with different content of KBr obtained in step 3), and then move the volumetric flask into the KQ3200E ultrasonic instrument with normal temperature ultrasound for 1 hour to prepare PBA / KBr suspensi...

Embodiment 3

[0045] A degradable polybutylene adipate / potassium bromide composite material and a preparation method thereof, characterized in that it comprises the following steps:

[0046] 1) Grind the potassium bromide particles for 2 hours and dry them in vacuum at 150°C for 1 week for use;

[0047] 2) Weigh PBA=0.2g, put it in a 10ml volumetric flask, use PBA's good solvent CHCl 3 Dilute the volume to 10ml, add a magnetic stirring rotor and magnetic stirring at room temperature for 30 minutes to completely dissolve the PBA, in triplicate;

[0048] 3) Weigh 0.002g and 0.02g of KBr described in step 1) and add them to the PBA solution obtained in step 2) to obtain three blended solutions with KBr content of 0wt%, 1wt% and 10wt% respectively;

[0049] 4) Add 0.1ml of deionized water to the PBA solution with different content of KBr obtained in step 3), and then move the volumetric flask into the KQ3200E ultrasonic instrument with normal temperature ultrasound for 1 hour to prepare PBA / KBr suspensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com