Pavement semi-rigid base material freeze thawing test machine

A semi-rigid base layer and testing machine technology, which is applied in the field of semi-rigid base layer frost resistance test of pavement engineering and pavement semi-rigid base layer material freeze-thaw testing machine, can solve the problem that the freezing temperature cannot be reached, the test piece cannot be frozen through, and the test accuracy is low. and other problems, to achieve the effect of reducing labor, shortening the test cycle, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

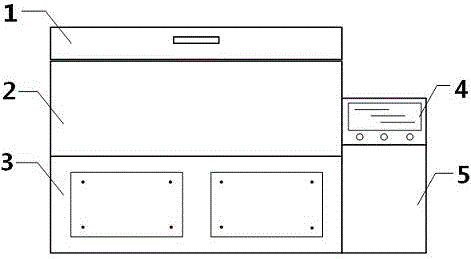

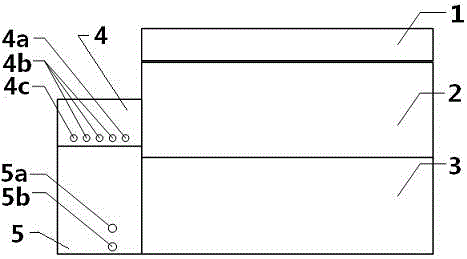

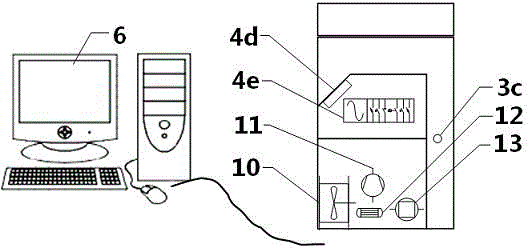

[0021] Examples of the present invention figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a test piece box, a water circulation system, a controller 4, a refrigeration system 5, and a computer 6;

[0022] Such as Figure 4 , Figure 6 As shown, the test piece rack 7 is a plate-type double-layer structure, and there is space in the lower part; the test piece rack 7 is installed in the test piece box 2; during the test, the test piece is placed on the test piece rack 7 in the test piece box 2 , to ensure that the specimens are evenly frozen.

[0023] Such as Figure 4 , Figure 7 As shown, the temperature-insulating transparent resin plate 8 has sensor jacks 8a of the test piece box, and the sensor jacks 8a are evenly distributed along the diagonal; the temperature-insulating transparent resin plate 8 is placed under the test p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com