Constant direct-axis current control method and system of embedded permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and direct axis current, which is applied in the direction of control system, vector control system, motor generator control, etc. Use and other problems to achieve good application prospects, simple system, and the effect of realizing unlimited speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

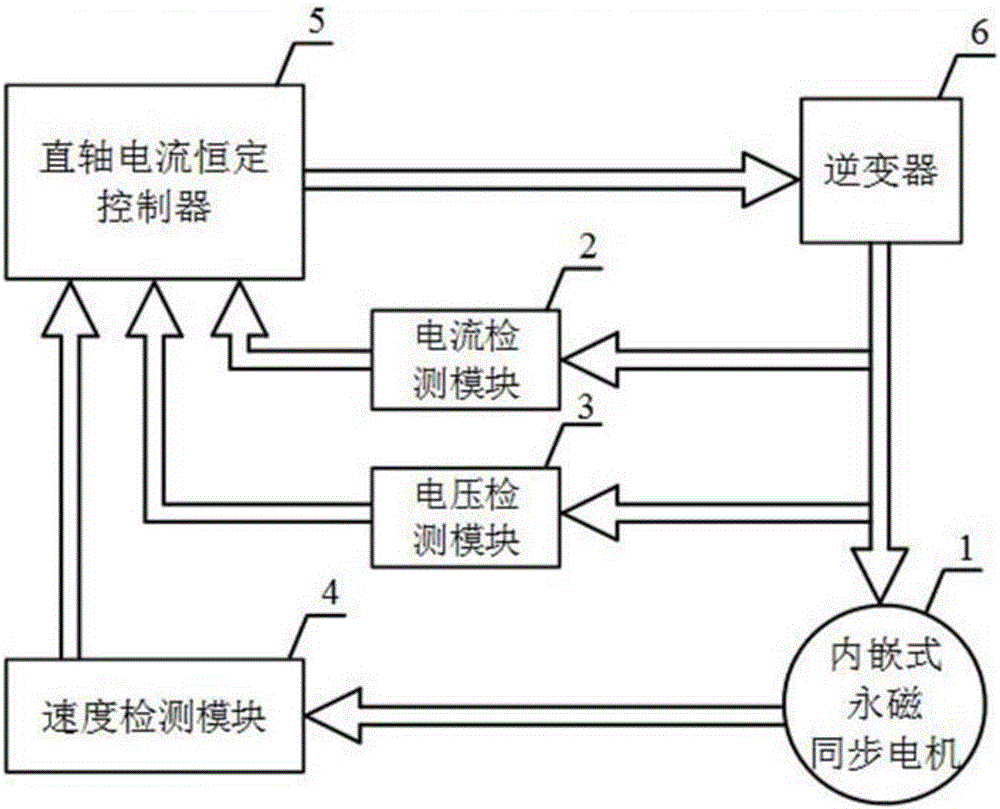

[0030] Such as figure 1 and figure 2 As shown, a method for controlling the constant direct axis current of an embedded permanent magnet synchronous motor in this embodiment is as follows:

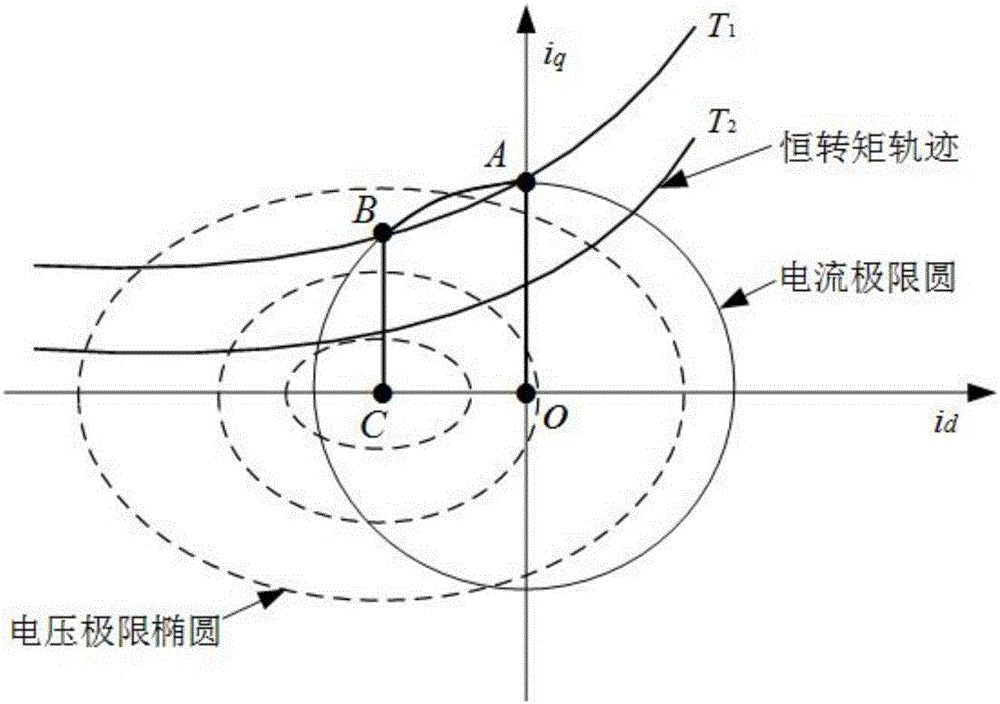

[0031] (a) Establish the control area: establish the direct axis current i d and quadrature current i q coordinate system i d -i q , at i d -i q In the coordinate system, the origin of coordinates is point O, and the current limit circle and i q The intersection point of the coordinate axes is point A, which is drawn by the center of the voltage limit ellipse perpendicular to i dThe intersection of the straight line of the coordinate axis and the current limit circle is point B, and the center point of the voltage limit ellipse is point C; the area formed by the OA line segment is the constant torque output control area, and the area formed by the BC line segment is the constant power output Control area; the area formed by the OA line segment and the BC line segment can transitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com