Corrosion resistant surface treatment method of chain parts

A surface treatment and parts technology, which is applied in the field of surface treatment of chain parts, can solve the problems of insufficient corrosion resistance and high cost of stainless steel chains, and achieve the effects of excellent corrosion resistance, high production efficiency and strong coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

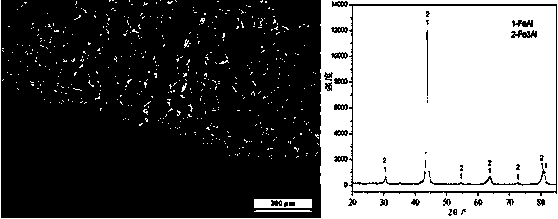

Embodiment 1

[0018] Pretreatment of 20CrMnTi steel pins of 08B roller chains: after surface rolling, degrease with 10wt% NaOH aqueous solution at 60°C for 10 minutes and wash with water; derust with 5wt% HCl aqueous solution at 40°C for 10 minutes and wash with water; immerse the pins at a temperature of 80°C 10wt%NaCl+15wt%KF aqueous solution for 10min, drying; immersion in molten aluminum solution at 720°C for 5min, taking it out and cooling to room temperature in air; under argon, diffusion treatment at 850°C for 2h to obtain 87μm The intermetallic compound coating; oil quenching of the diffused pin shaft parts, followed by tempering at 200 ° C for 2 hours and then cooling.

Embodiment 2

[0020] Pretreatment of 16A roller chain 40Cr steel chain plate: after surface rolling, 20wt% NaOH aqueous solution at 50°C for 12 minutes, and water washing; 8wt% HCl aqueous solution at 50°C for 8 minutes, and water washing; 5wt%NaCl+3wt%KF aqueous solution for 20min, drying; immersion in molten aluminum solution at 750°C for 1min, taking it out and air cooling to room temperature; under protective atmosphere of argon, 900°C diffusion treatment for 1.5h, A 165 μm intermetallic compound coating was obtained; the diffused plate was directly oil-quenched, then tempered at 400°C for 2 hours and then cooled.

Embodiment 3

[0022] Pretreatment of 20A roller chain 20 steel sleeves and rollers: after surface tumbling, degrease with 15wt% NaOH aqueous solution at 60°C for 10 minutes and wash with water; derust with 20wt% HCl aqueous solution at 60°C for 5 minutes and wash with water; Help plating in 8wt%NaCl+9wt%KF aqueous solution at 75°C for 15min, dry; immerse in molten aluminum solution at 730°C for 3min, take it out and air cool to room temperature; in protective atmosphere of argon, 1000°C diffusion treatment After 30 minutes, a 176 μm intermetallic compound coating was obtained, followed by oil quenching and tempering at 200°C for 2 hours and then cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com