Aluminum-alloy tank melon petal punching device and punching method

A technology of aluminum alloy and melon petals, which is applied in the field of aerospace design and manufacturing, can solve problems such as over-burning of parts, tensile strength and yield strength indicators that cannot meet the design requirements, and achieve low manufacturing cost, wide application range and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

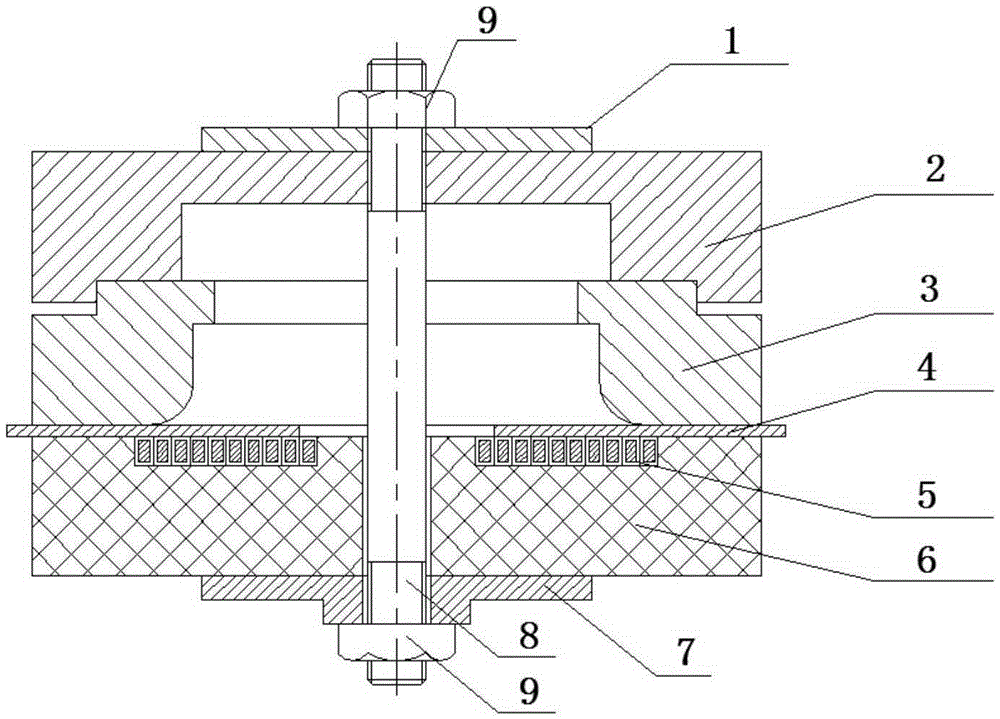

[0032] Such as figure 1 As shown, the device includes an upper pressing block 2 , a forming die 3 , an insulating backing plate 6 and a lower pressing block 7 installed coaxially.

[0033] The forming die 3 is installed above the insulating backing plate 6 , and an installation groove is processed on the upper surface of the insulating backing plate 6 to place the inductor coil 5 . The parts 4 to be processed are placed between the forming die 3 and the inductor coil 5 . The upper pressing block 2 is installed on the forming die 3 to play the role of positioning and pressing. The lower pressing block 7 is located below the insulating backing plate 6 .

[0034] Said coaxial installation means that the upper pressing block 2, the forming die 3, the insulating backing plate 6 and the lower pressing block 7 are coaxially installed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com