Method for making fabric containing nano particles

A technology of nanoparticle and production method, which is applied in the production field of fabric containing nanoparticle, can solve the problems of complex production process and single function of fabric, and achieve the effect of simple operation process, not easy to fade, and suitable for small batch production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Put 55g of solid powder water-based dye into the container, then add 21g of nano-silver and nano-titanium dioxide powder into the container and add an appropriate dispersant, take 50g of warm water and put it in the container at 40-50°C for 50 minutes Stir. According to the color of dyed cloth or bleaching, put 1kg of water into the dye vat and heat it up. The temperature of the water in the dye vat is controlled at 50°C. Pour the mixed nano-fuel liquid in the container into the dye vat and stir for 3 hours to form a nano-antibacterial dye solution, and then put the gray cloth into the dye vat to stir and dye for half an hour. Then wash with water and dry at 120°C to obtain nano antibacterial and anti-ultraviolet cloth.

[0026] The above-mentioned antibacterial and anti-ultraviolet cloth test results show that: the bactericidal rate of the cloth for 2 hours is 99.8% for Escherichia coli and 99.3% for Staphylococcus aureus.

[0027] This product effectively...

Embodiment 3

[0031] Embodiment 3: antibacterial, the preparation method of anti-ultraviolet printing and dyeing cloth

[0032] Put 200g of printing and dyeing paste into a vacuum stirring container, then respectively put 4g of nano-silver and nano-titanium dioxide into a vacuum stirring container and add a dispersant, and carry out vacuum stirring for 10 hours, so that the nanoparticles are uniformly mixed in the printing and dyeing paste, and then Send the stirred printing and dyeing paste into the dye chamber of the printing and dyeing machine for printing and dyeing. Then wash with water and dry at a temperature of 120° C. to obtain nano antibacterial and anti-ultraviolet cloth.

[0033] The above-mentioned antibacterial and anti-ultraviolet cloth test results show that: the bactericidal rate of the cloth for 2 hours is 99.8% for Escherichia coli and 99.2% for Staphylococcus aureus.

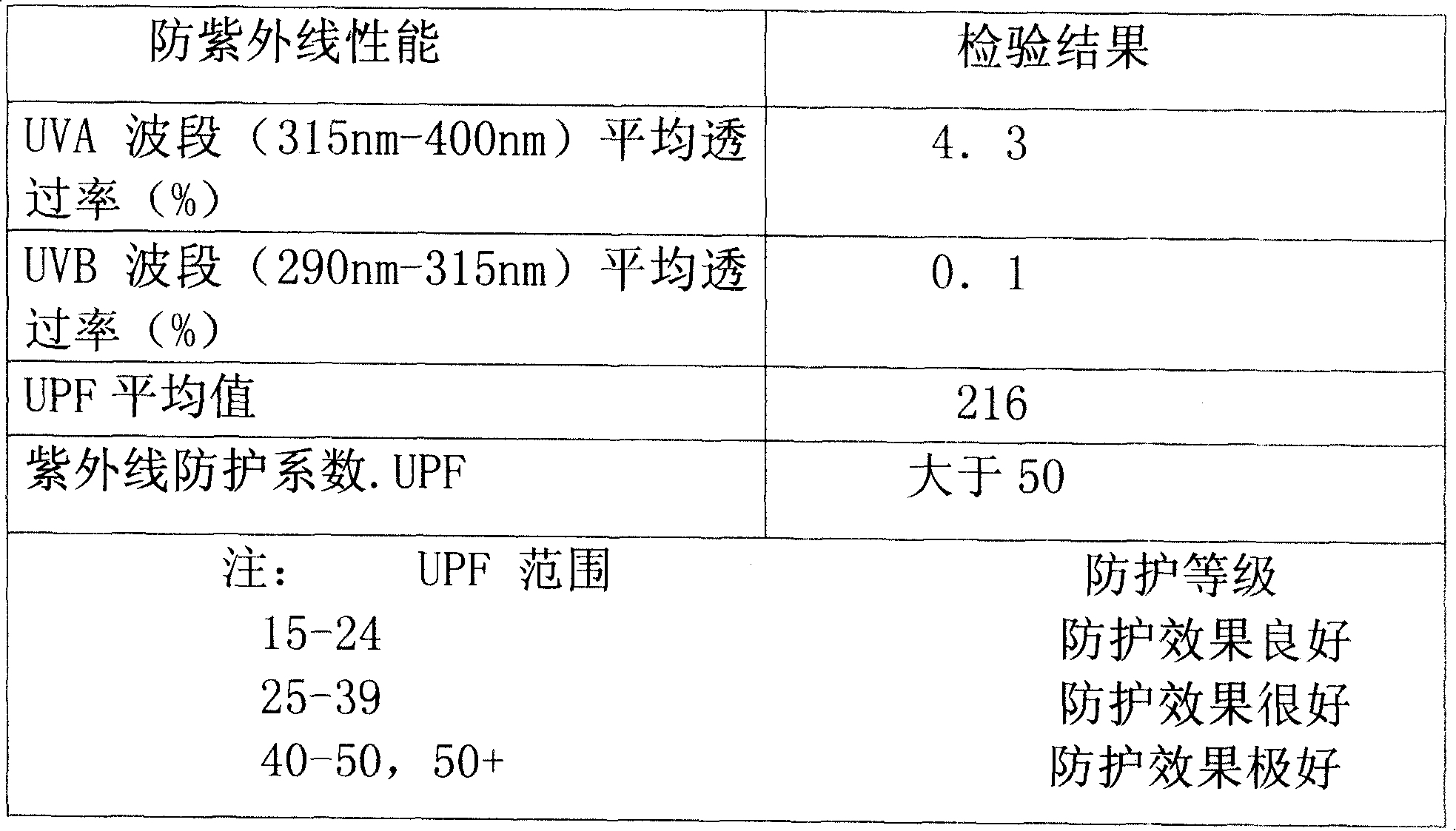

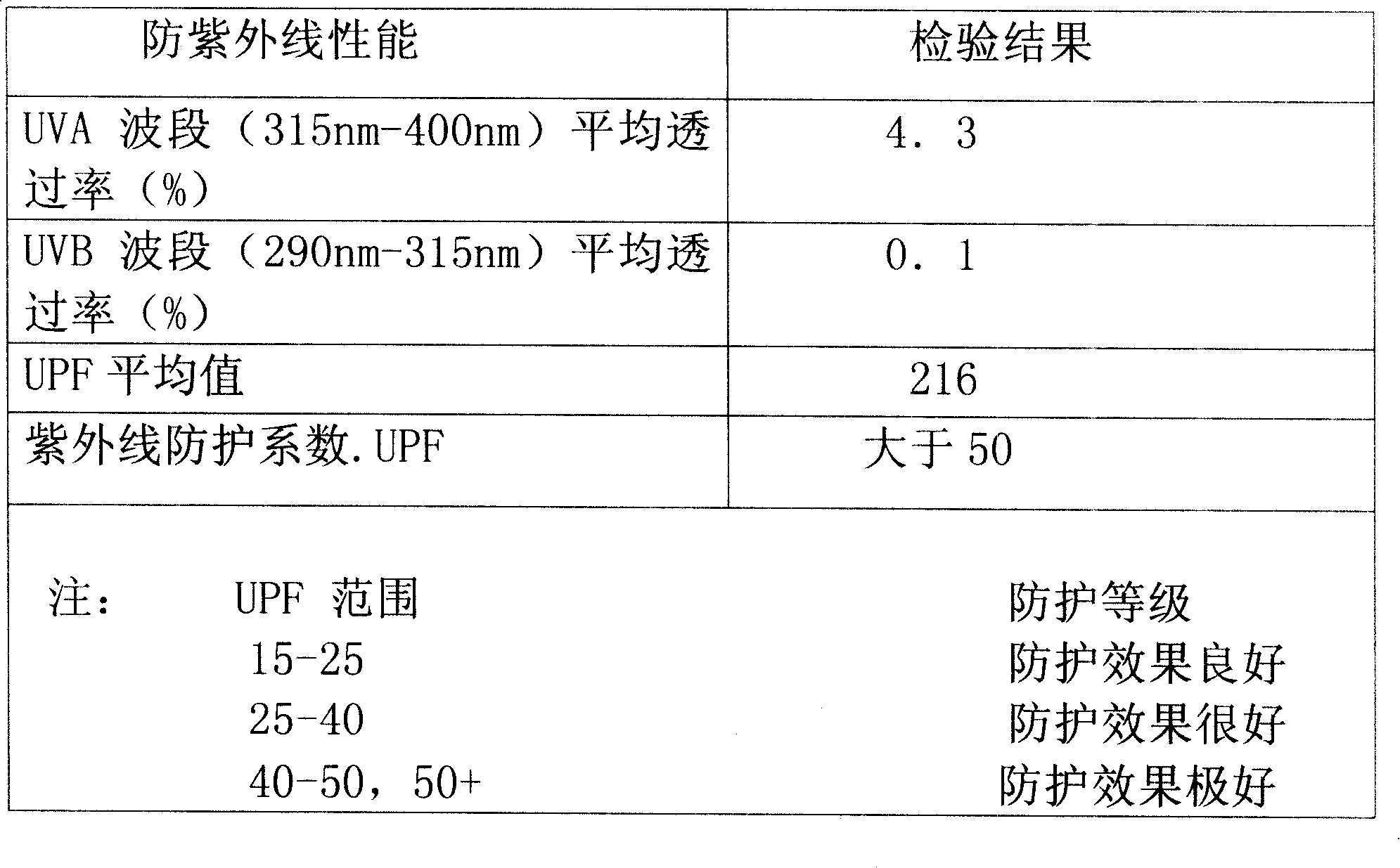

[0034] This product effectively prevents harmful ultraviolet rays to the human body: the following tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com