Device for removing hub rim burrs

A deburring and wheel hub technology, which is applied in the field of burring devices, can solve the problems of affecting the appearance effect, wheel flange corrosion, wheel hub corrosion, etc., and achieve the effects of uniform deburring, improved automation, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

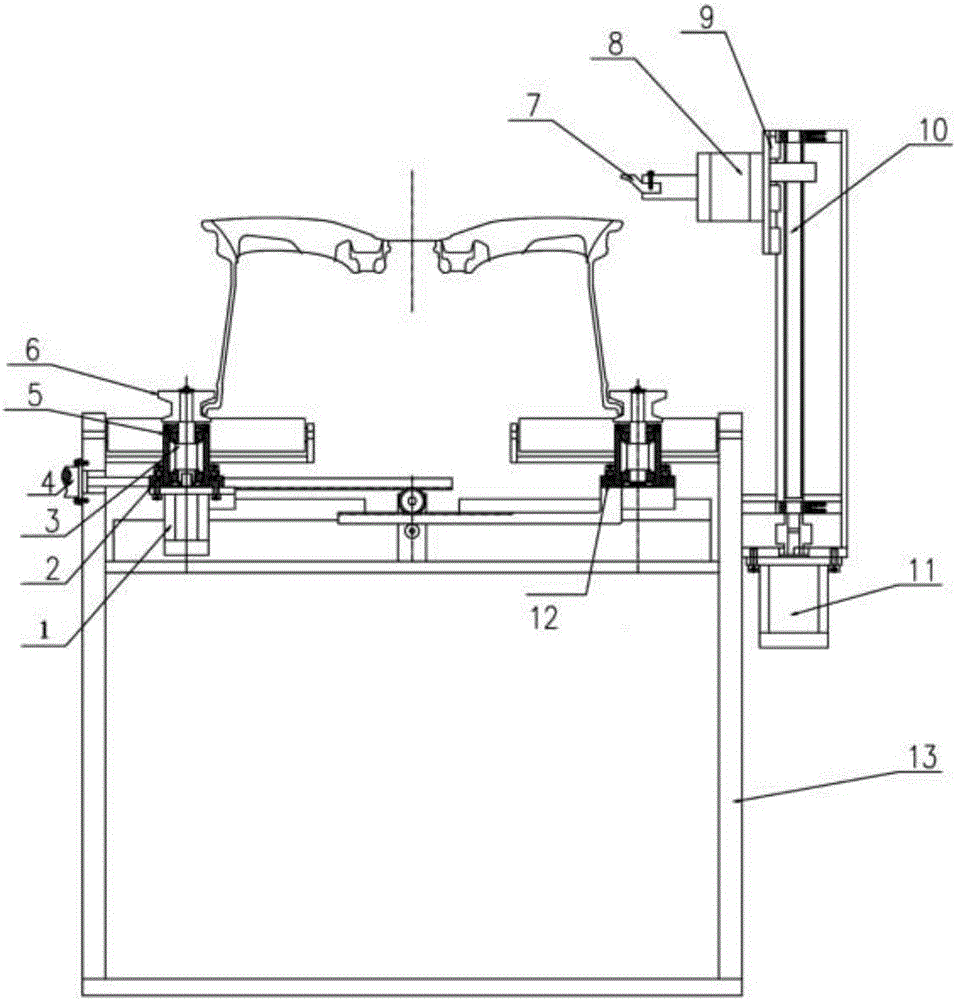

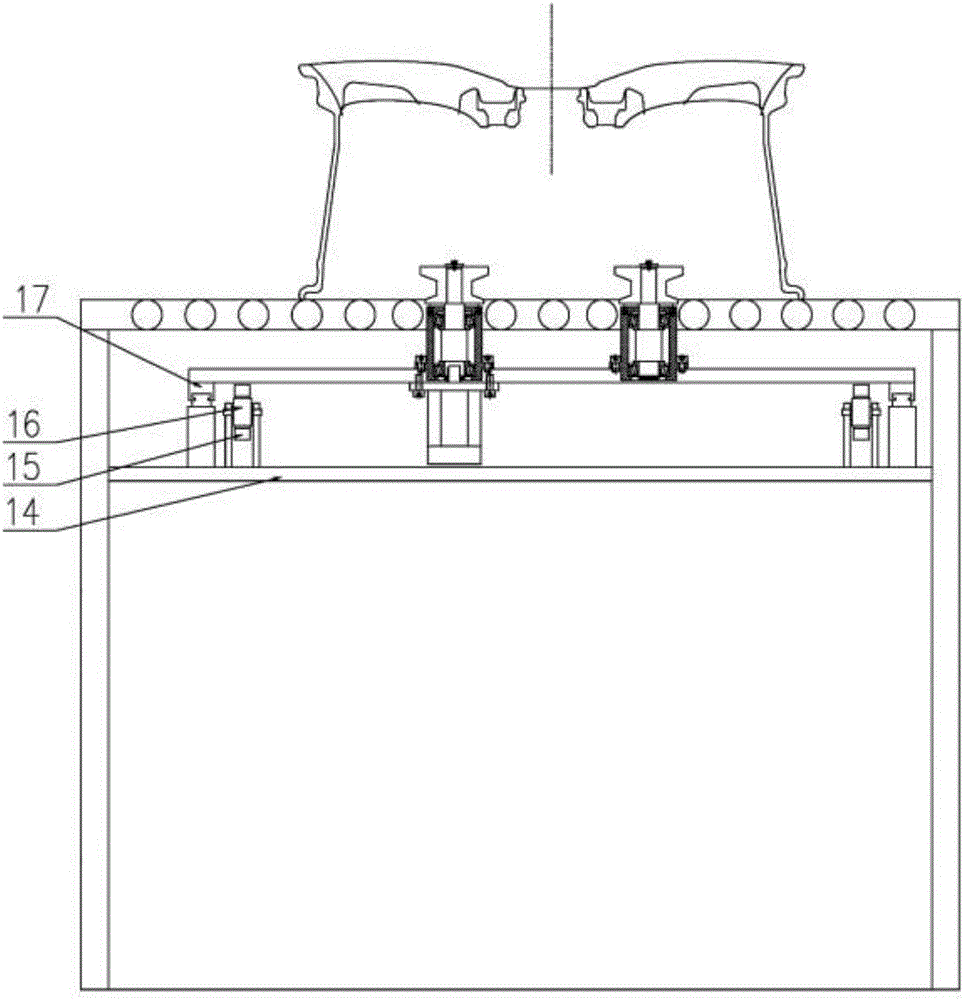

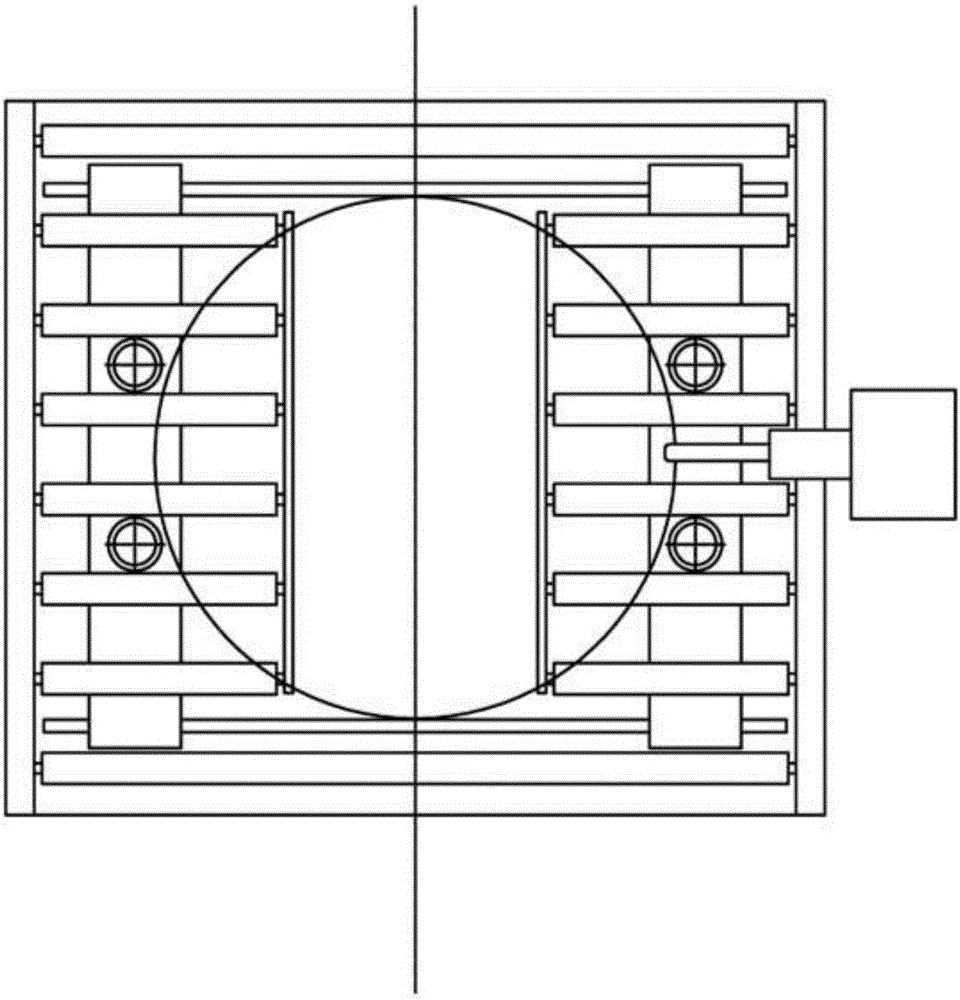

[0017] The details and working conditions of the specific device proposed by the present invention will be given below in conjunction with the description of the accompanying drawings.

[0018] A device for removing burrs from the rim of a wheel hub, which consists of a clamping roller servo motor 1, a left slide plate 2, a shaft 3, a clamping cylinder 4, a bearing seat 5, a clamping roller 6, a burr knife 7, a linear motor 8, a lifting Platform 9, ball screw 10, lifting motor 11, right slide 12, frame 13, support plate 14, rack 15, gear 16, guide rail 17, left slide 2 and right slide 12 are connected through gear 16 and rack 15 , the clamping cylinder 4 drives the rack 15 to move, and the synchronous movement of the left skateboard 2 and the right skateboard 12 is realized through the meshing of the rack 15 and the gear 16, thereby controlling the synchronous clamping and loosening of the clamping roller 6. The lifting motor 11 is fixed on the frame 13, the linear motor 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com