Laser large-cutting-depth trimming device and method for formed grinding wheel

A technology for forming grinding wheels and dressing devices, which is used in laser welding equipment, abrasive surface adjustment devices, grinding/polishing equipment, etc., can solve problems such as low dressing efficiency and poor dressing quality, and achieve high-efficiency, precise shaping and good removal uniformity. , highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

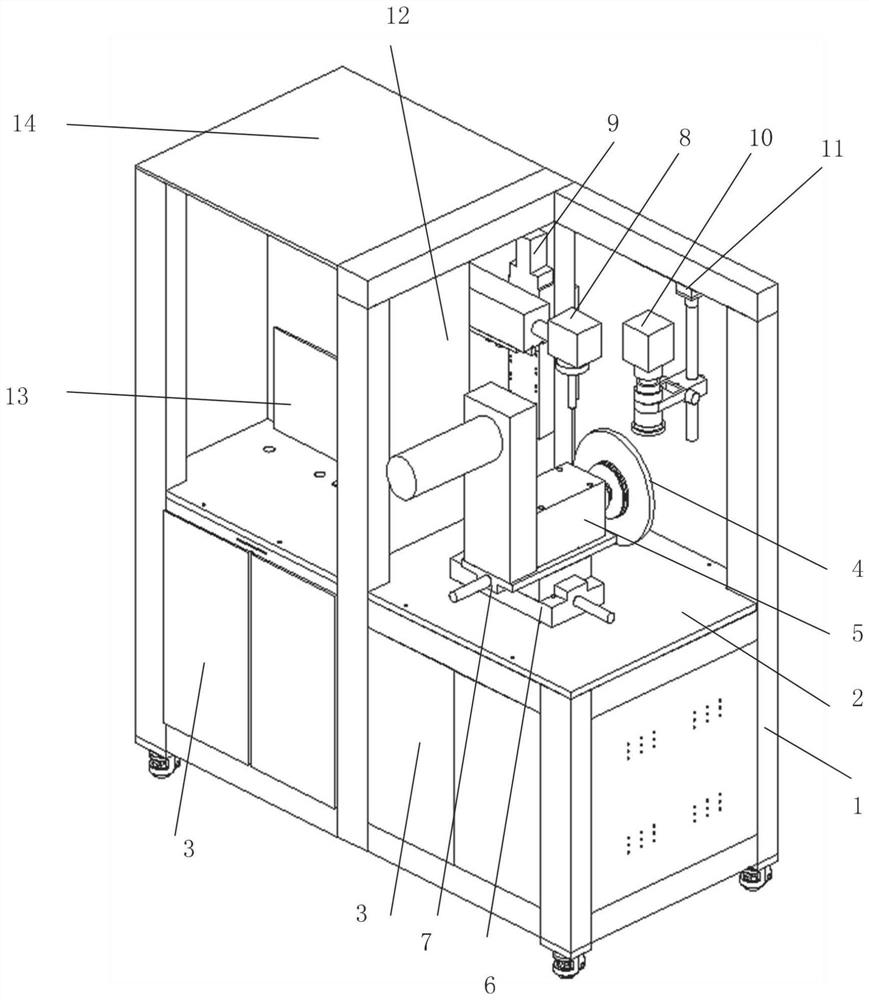

[0077] as Figure 1-Figure 6 As shown, the forming grinding wheel laser large cut depth trimming apparatus described in the present embodiment, comprising truss 1, working platform 2, cabinet 3, grinding wheel 4, motor 5, Y-direction manual slide 6, X-direction manual slide 7, laser, laser vibrator 8, Z-direction electric slide 9, super depth of field microscope 10, A-direction electric slide 11, radiation-proof glass 12, display 13, aluminum profile cover 14.

[0078] The working platform 2 is set horizontally and mounted on truss 1, combined with the attached Figure 1 Shown, truss 1 mainly plays the role of supporting the skeleton; the working platform 2 is horizontal, mounted on the truss 1, the lower part of the working platform 2 is the box cabinet 3, preferably, the truss 1 is a steel profile or aluminum profile, the working platform 2 is made of cast iron, the cast iron flatness is high, the load-bearing capacity is strong, and it can provide stable and flat support for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com