Sewing machine for weaving end products of Chinese knots from woolen yarn clews

A technology for sewing machines and wool balls, which is applied in the direction of sewing machine components, sewing machine control devices, sewing equipment, etc., and can solve problems such as the inability of the cloth to be fed to the needle drop, unqualified sewing products, and sewing failure, etc., and achieve trimming accuracy High, improve the quality, reduce the effect of vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be described below in conjunction with specific embodiments.

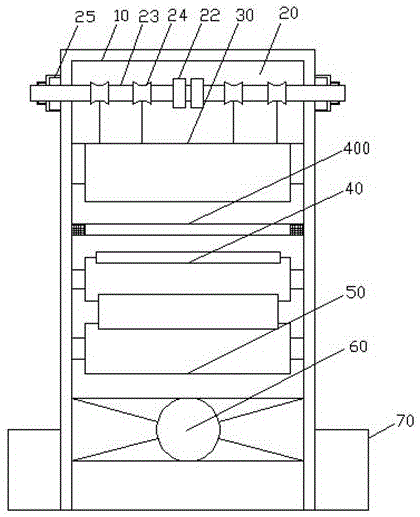

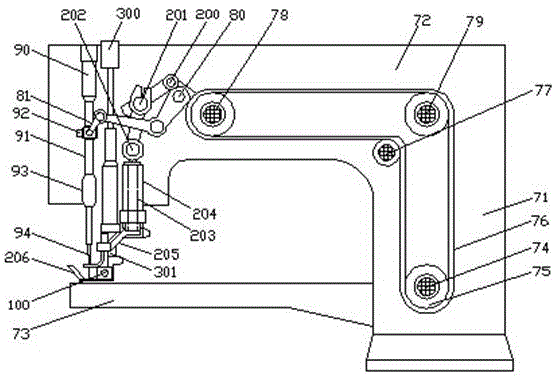

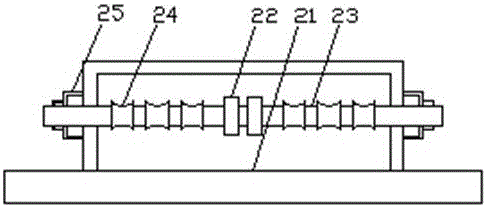

[0027] Such as figure 1 with Figure 7 Shown is a structural schematic diagram of a Chinese knot sewing machine from wool ball to finished product according to the present invention.

[0028]A Chinese knot sewing machine from wool balls to finished products according to the present invention includes: a frame 10, which is sequentially provided with a wire feeding mechanism 20, a pulling thread mechanism 30, a textile mechanism 40, a trimming mechanism 50 and Winding mechanism 60, frame 10 bottom is also provided with the sewing mechanism 70 that is arranged in parallel with winding mechanism 60; Head 72, arm foot portion 71 and arm head portion 72 have constituted the arm portion structure that is L-shaped, and sewing machine base also comprises one end and arm foot portion 71 is fixed and is parallel to the tubular cylinder that arm head portion 72 is arranged. 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com