Formed plate edge cutting machine

A technology of forming boards and trimming machines, applied in forming/shaping machines, special forming/shaping machines, metal processing, etc., can solve problems such as difficulty in meeting process requirements, low cutting efficiency, and low cutting accuracy, and achieve The structure is simple, the production is convenient, and the effect of improving the trimming accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

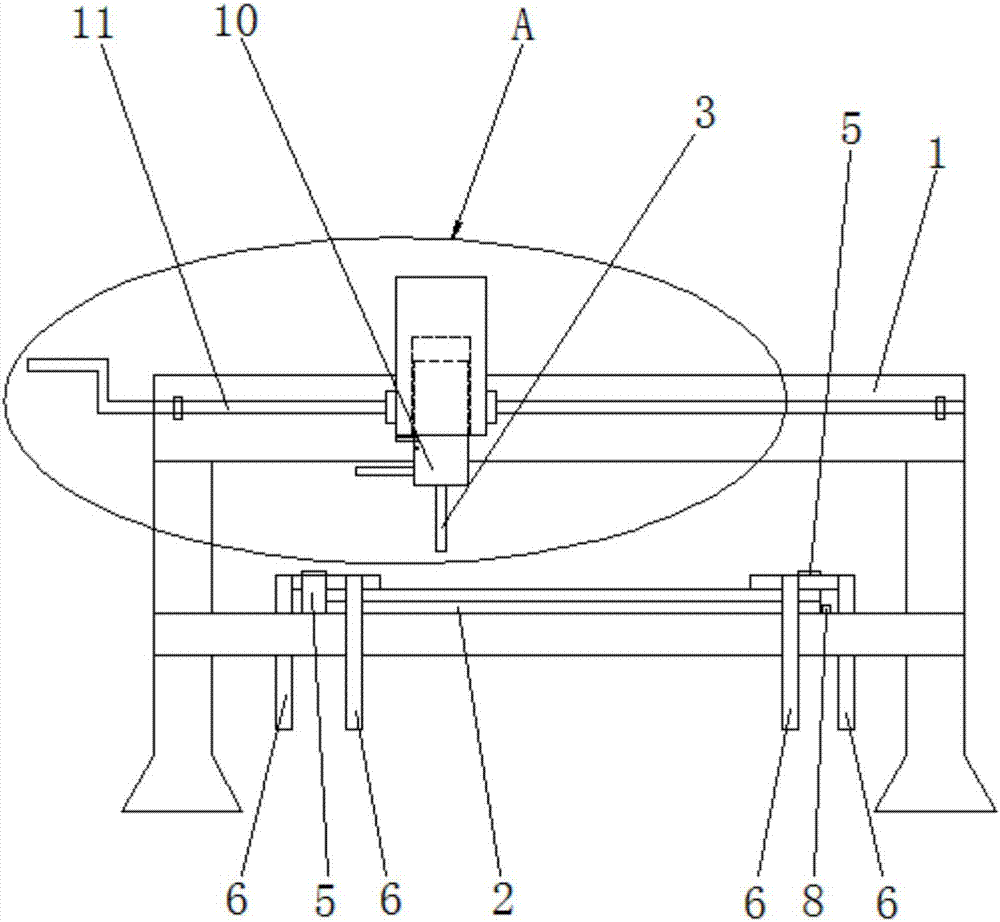

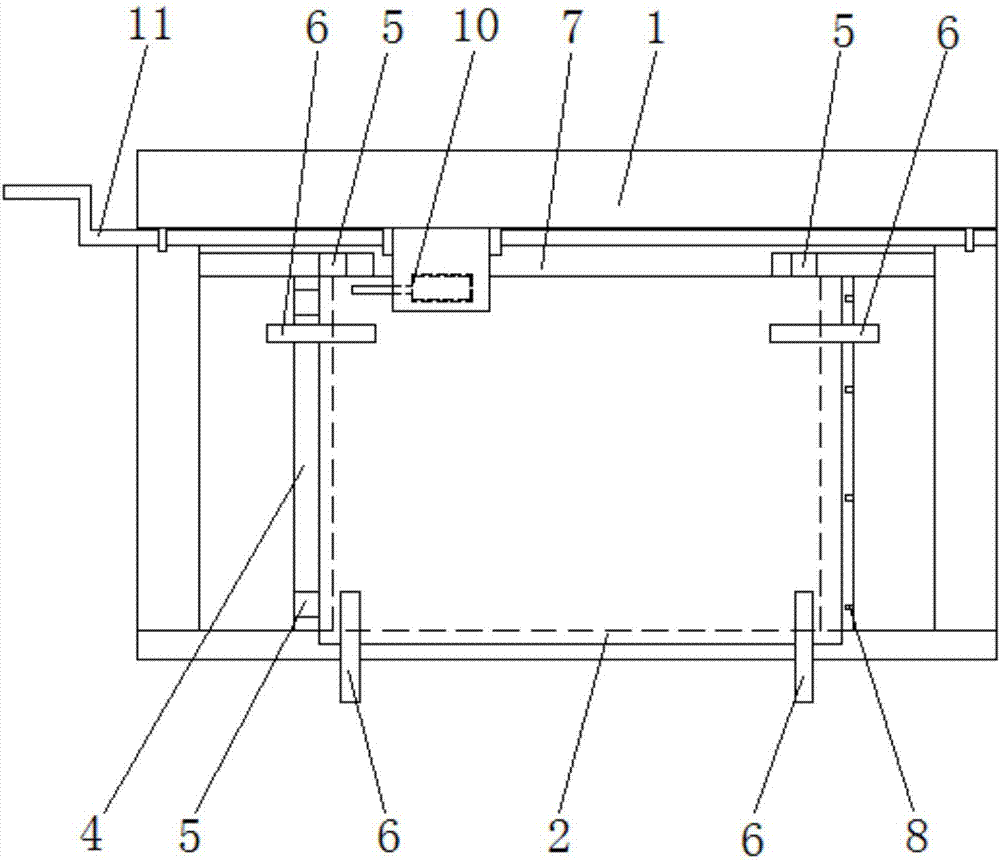

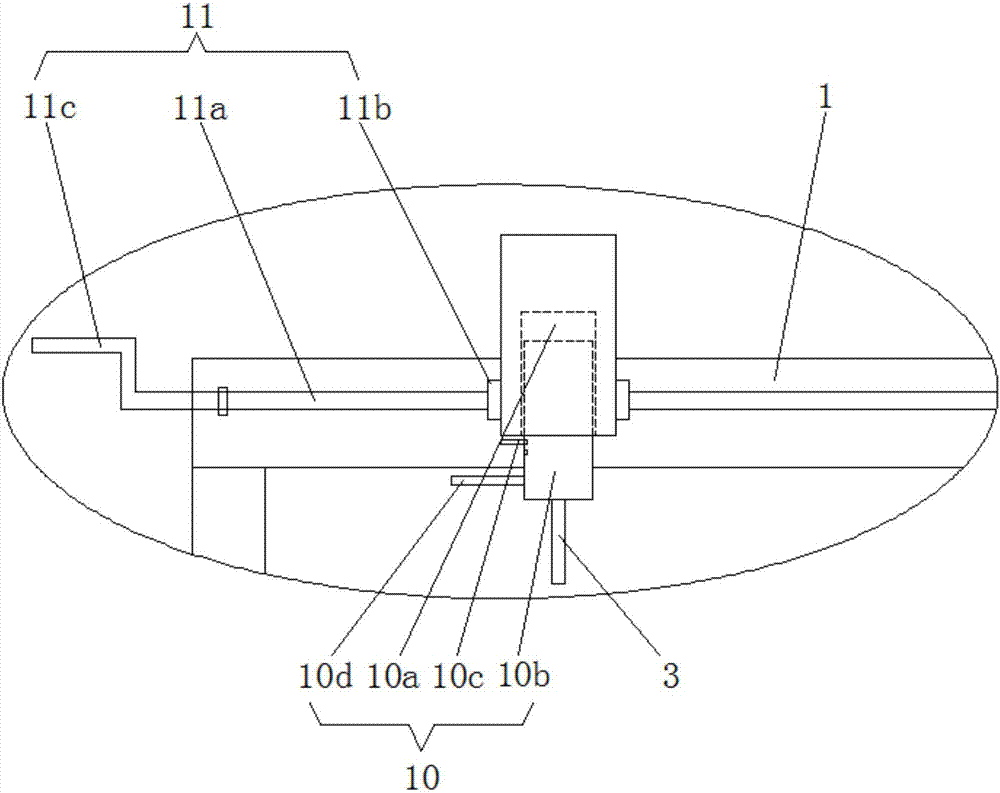

[0024] refer to Figure 1-5 , a kind of molding board trimming machine of the present invention comprises workbench 1, and this workbench 1 is frame structure, comprises four supporting feet, and the working platform erected on the supporting feet, and erected on one side of the working platform A crossbeam, above the workbench 1 is provided with a cutting tool 3 that can reciprocate along the workbench 1 left and right, up and down, and can cut a plurality of forming plates 2 at the same time. The cutting tool 3 is arranged on the beam of the workbench 1 and along Beam up and down, left and right directions (corresponding figure 1 Up and down, left and right directions) in order to achieve the purpose of edge trimming, a support frame 4 supporting the forming board 2 is provided on the workbench 1, and the width of the support frame 4 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com