A high-efficiency polishing disc with shear expansion characteristics and its preparation method

A technology of expansion characteristics and polishing discs, which is applied in the field of ultra-precision polishing, can solve the problems of small range and poor surface flatness of the polished workpiece, and achieve the effect of low cost, large processing contact area and good removal uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the high-efficiency polishing disc with shear expansion characteristics comprises the following steps:

[0032] 1) Preparation of materials with non-Newtonian fluid properties: After fully mechanically stirring the viscoelastic polymer, abrasive grains 7, and dispersant 8 in proportion, the mass percentage is: 69% to 85% of the viscoelastic polymer, with a particle size of 10% to 30% of abrasive particles between 0.05 and 50 μm, 1% to 5% of dispersant, and stand in an oven at 120 to 200°C for 2 to 5 hours to prepare a material with non-Newtonian fluid characteristics;

[0033] 2) Prepare the polishing layer 2. Method 1: Mix the adhesive, curing agent and other components according to the proportion, put them into the mold, heat them in the oven, and get a base plate with grooves after cooling, fill the above-mentioned materials with non-Newtonian fluid characteristics into the Obtaining the polishing layer 2; method 2: heating and melting the ...

Embodiment 1

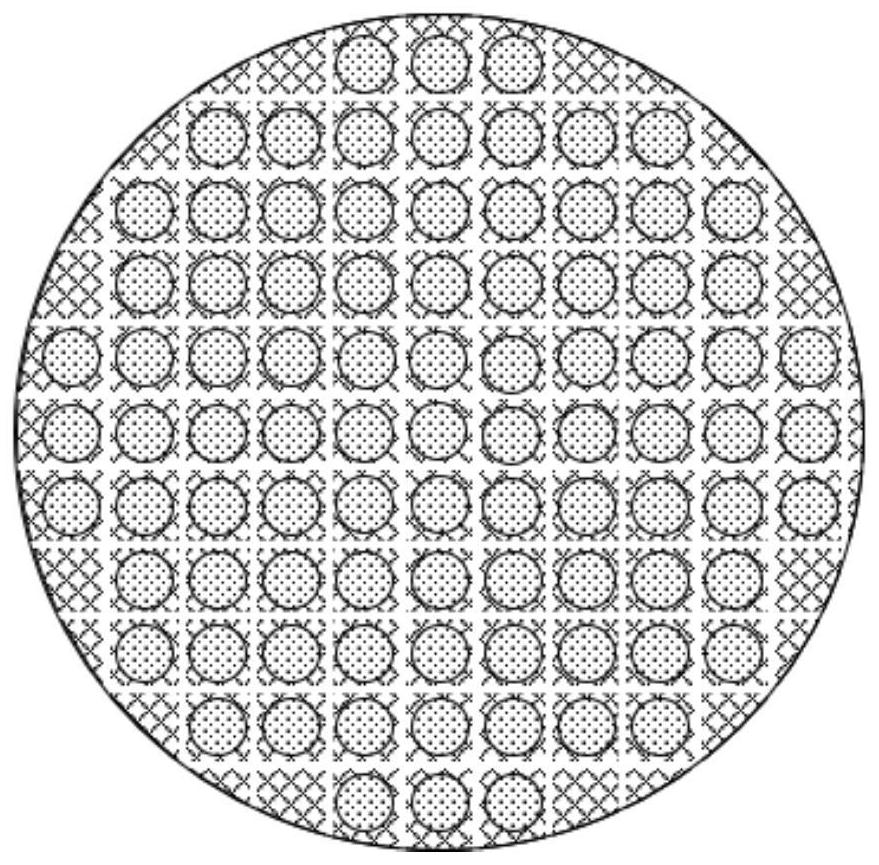

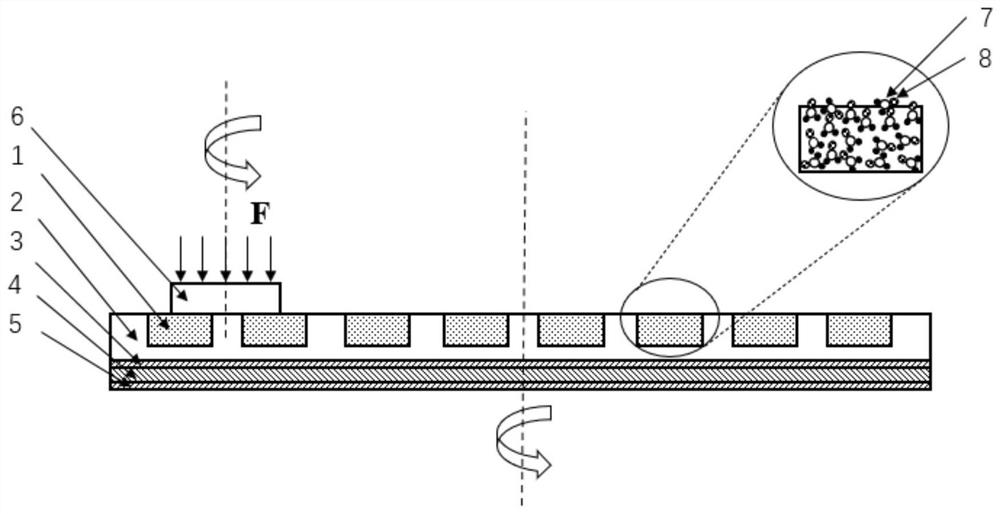

[0048] refer to figure 1 and figure 2 , a high-efficiency polishing disc with shear expansion characteristics, comprising a polishing layer 2, a rigid layer 4 and an adsorption layer 5, the preparation method of the high-efficiency polishing disc comprises the steps of:

[0049] 1) 85g of viscoelastic polymer, 10g of diamond abrasive particles 7 with a particle size of 1.5μm, and 5g of sodium dodecylbenzenesulfonate 8 were fully mechanically stirred evenly, and then heated in an oven at 120°C for 2h to prepare a non-Newtonian Materials with fluid properties;

[0050] 2) Evenly mix 90% polyurethane binder and 10% curing agent to form a viscous mixture, put the viscous mixture into a mold, heat and press under a hot press, and let it stand for 24 hours Obtain the embryo body. Put the embryo body together with the mold into the oven, heat and dry it at 120°C for 2 hours, so that it can be fully cured to become the desired substrate. The substrate is placed on the grinder and...

Embodiment 2

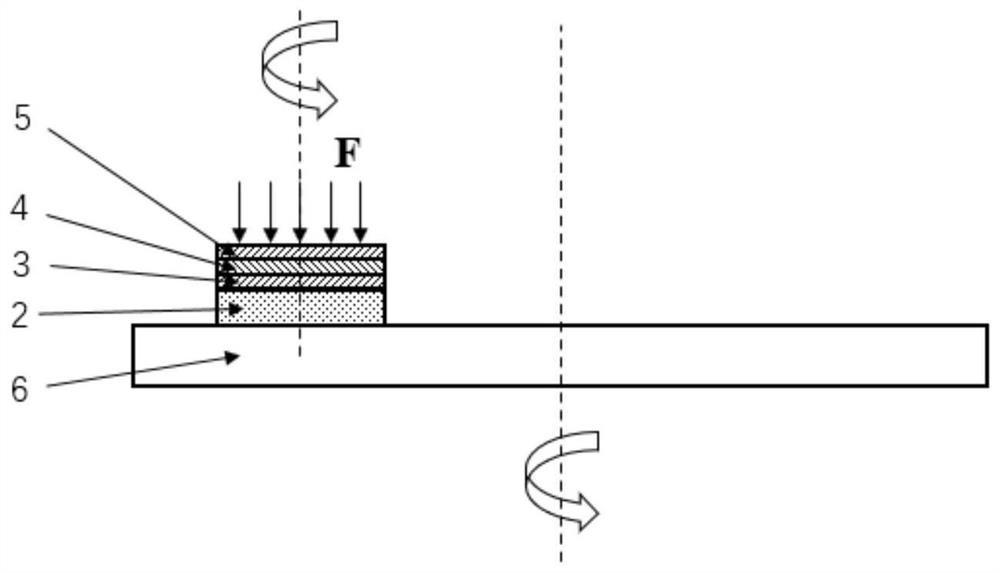

[0057] refer to image 3 , a high-efficiency polishing disc with shear expansion characteristics, comprising a polishing layer 2, a rigid layer 4 and an adsorption layer 5, the preparation method of the high-efficiency polishing disc comprises the steps of:

[0058] 1) 78g of viscoelastic polymer, 20g of alumina abrasive particles 7 with a particle size of 1.5μm, and 2g of sodium dodecylbenzenesulfonate 8 were fully mechanically stirred evenly, and then heated in an oven at 150°C for 3h to prepare a molten state materials with non-Newtonian fluid properties.

[0059] 2) Prepare a piece of non-woven fabric, uniformly embed the material with non-Newtonian fluid characteristics in the molten state in the above step 1) in the non-woven fabric, and obtain the polishing layer 2 after cooling;

[0060] 3) Select a rigid polymer as the rigid layer 4, and bond it to the polishing layer through the resin bond 3;

[0061] 4) Attach the polishing disc to the polishing tool through doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com