Preparation method of self-aligned contact hole

A self-aligned contact hole and self-aligned contact technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc., can solve problems such as high cost and difficult polymer monitoring and control , to achieve the effect of ensuring uniformity, good removal uniformity, and avoiding excessive polymer residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

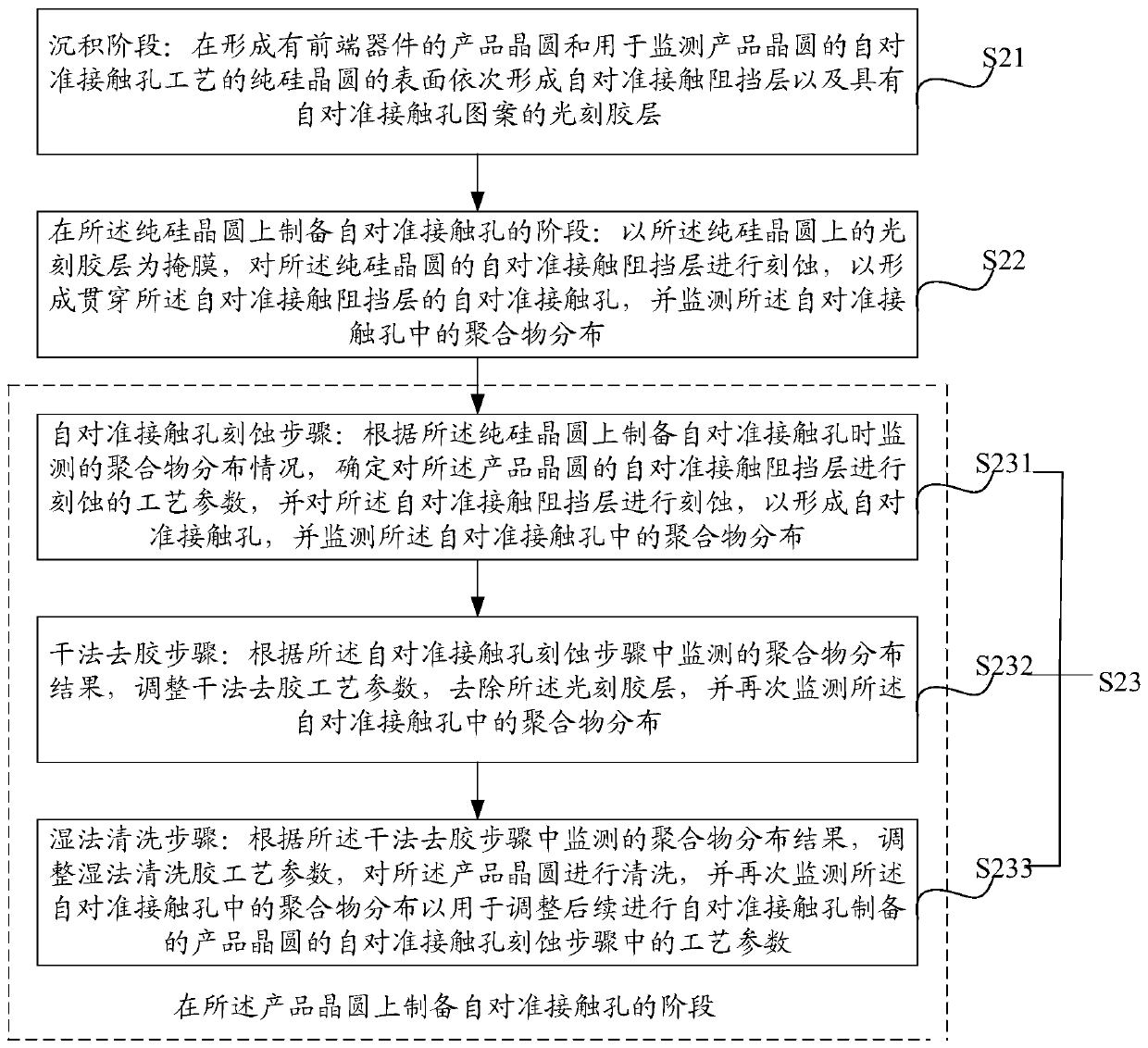

[0030] Please refer to figure 2 , this embodiment provides a method for preparing a self-aligned contact hole, including:

[0031] S21, deposition stage: sequentially form a self-aligned contact barrier layer and a barrier layer with A photoresist layer for self-aligned contact hole patterns;

[0032] S22, the stage of preparing a self-aligned contact hole on the pure silicon wafer: using the photoresist layer on the pure silicon wafer as a mask, using a fluorocarbon gas with a fluorocarbon ratio not greater than 2 to treat the The self-aligned contact barrier layer of the pure silicon wafer is etched until the surface of the pure silicon wafer is exposed, so as to form a self-aligned contact hole penetrating through the self-aligned contact barrier layer, and monitor the Polymer distribution in self-aligned contact holes;

[0033] S23, the stage of preparing self-aligned contact holes on the product wafer, including:

[0034] S231, self-aligned contact hole etching step: u...

Embodiment 2

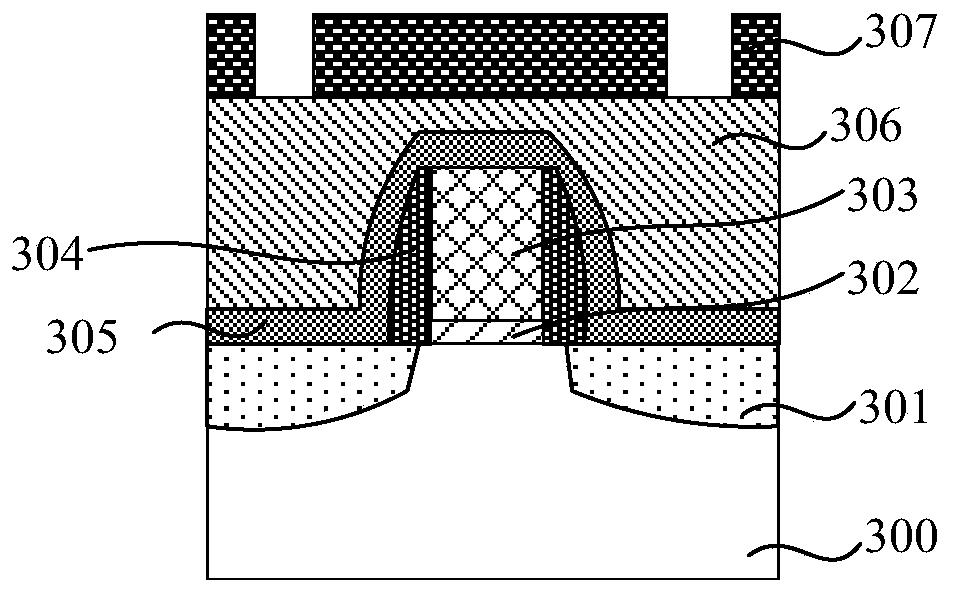

[0048] Please refer to Figure 4 , this embodiment provides a method for preparing a self-aligned contact hole, including:

[0049] S41, deposition step: sequentially forming a doped silicon oxide glass layer, a protective oxide layer, and a photoresist layer with a self-aligned contact hole pattern on the surface of the substrate wafer;

[0050] S42, the initial etching step of the self-aligned contact hole: using the photoresist layer as a mask, etching the protective oxide layer to the surface of the doped vitreous silica layer, so as to form the protective oxide layer through the and monitoring the polymer distribution in the openings of the protective oxide layer;

[0051] S43, dry stripping step: according to the polymer distribution result in the opening of the protective oxide layer, adjust the parameters of the dry stripping process, remove the photoresist layer, and monitor again the polymer in the self-aligned contact hole polymer distribution;

[0052] S44, self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com