Device for cleaning brake disc

A technology for cleaning devices and brake discs, applied to cleaning methods and tools, cleaning methods using tools, and drying solid materials without heating, etc., can solve the problems of time-consuming cleaning of brake discs, safety accidents affecting brake performance, etc. problems, to achieve the effect of improving cleaning efficiency, shortening cleaning time and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

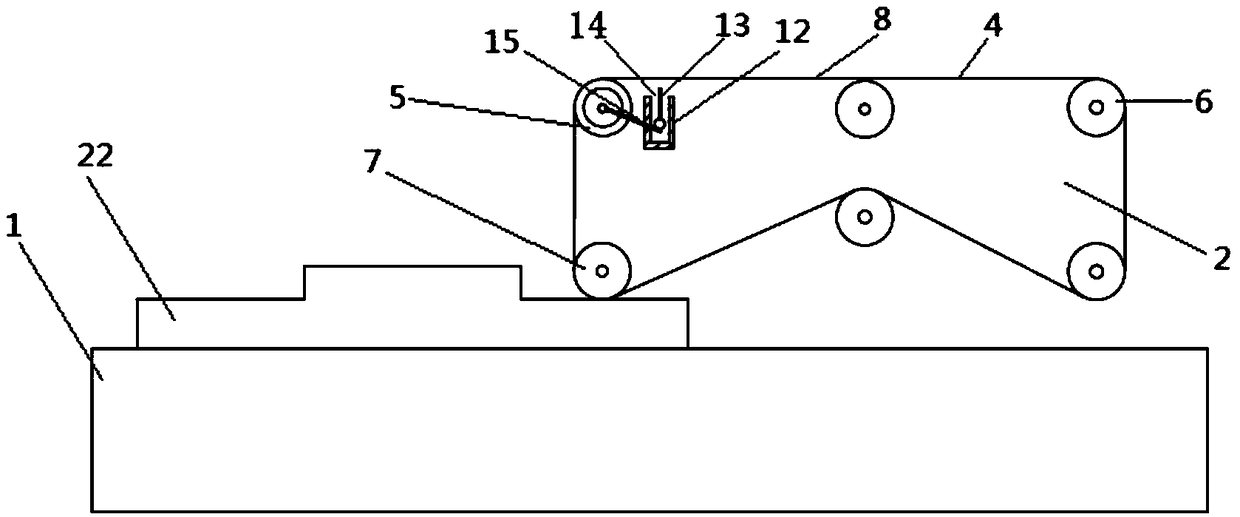

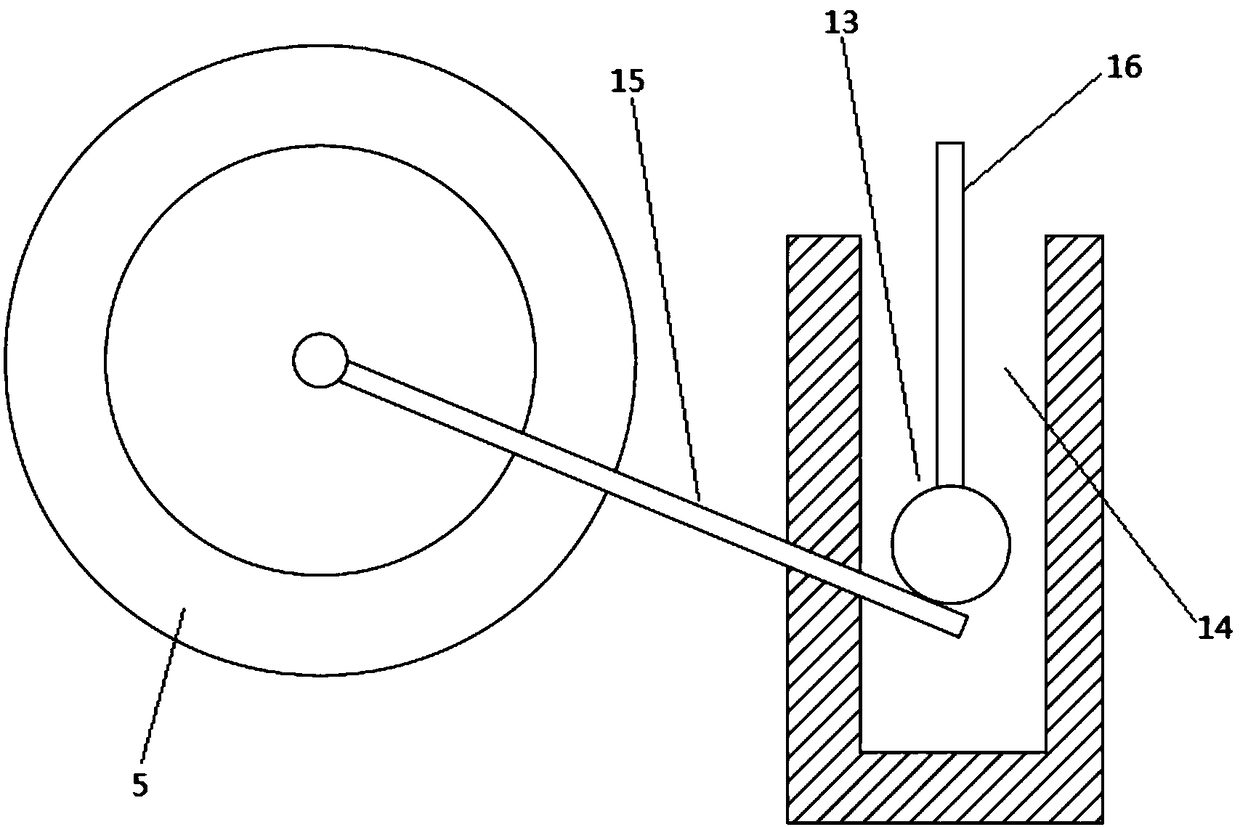

[0031] This embodiment is basically as figure 1 Shown: a brake disc cleaning device, including a support base 1, a cleaning part 2 and a power unit, and the power unit is set as a drive motor. The cleaning unit 2 is provided with a rotating belt 4, a conveying roller 5, a rotating roller 6 and a pressure roller 7, the rotating belt 4 is wound on the conveying roller 5, the rotating roller 6 and the pressing roller 7, and the power unit drives the rotating roller 6 to rotate.

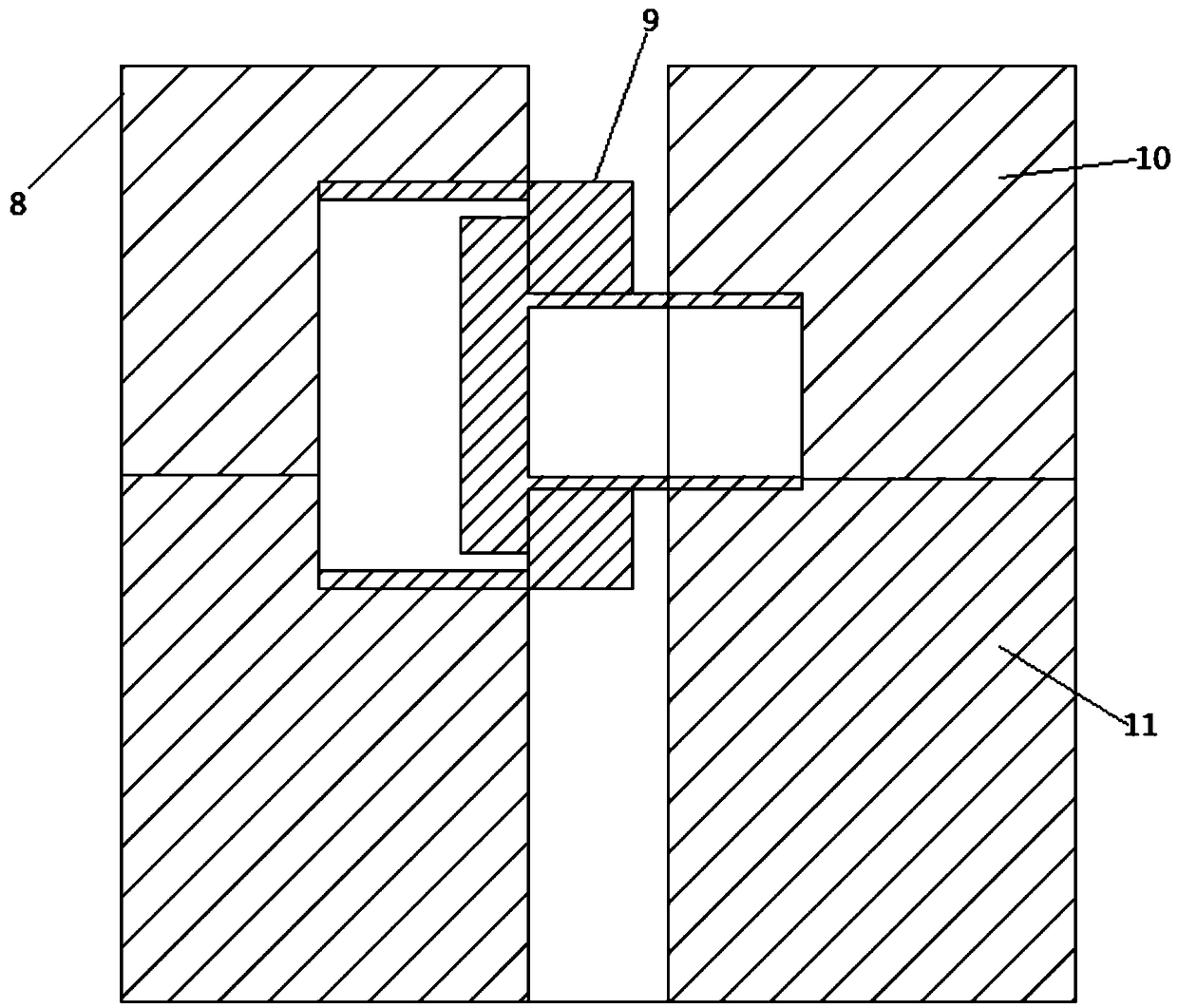

[0032] Rotating belt 4 comprises some cleaning belts 8 and rotating shaft 9, as figure 2 , 5 As shown, the adjacent cleaning belts 8 are hinged end to end through the rotating shaft 9, and the cleaning belts 8 are evenly divided into upper and lower layers with different materials. The upper water-absorbing layer 10 is set to be made of cotton material, the cleaning layer 11 is set to be made of rubber material, and the rotating shaft 9 is set in one layer of cotton material.

[0033] The cleaning se...

Embodiment 2

[0037] Such as Figure 6 As shown, the brake disc cleaning device, the difference between this embodiment and the above embodiments is that: the support base 1 is provided with a rotating unit for driving the brake disc 22 to rotate, and the rotating unit in this embodiment is the rotating shaft 21 . Such as Figure 9 As shown, the pressing roller 7 is provided with a protrusion for pushing out the cleaning belt 8 for pushing out the cleaning belt 8 . Such as Figure 8 As shown, the conveying roller 5 is provided with a groove for placing the cleaning belt 8, and the cleaning belt 8 is positioned in the groove during device operation.

[0038] During specific implementation, the rotating shaft 21 is powered by the driving motor to rotate, so that the brake disc 22 rotates, which facilitates the cleaning part 2 to clean the brake disc 22, can clean the brake disc 22 more fully, and improves cleaning efficiency. In addition, a protrusion is provided on the pressure roller 7 ,...

Embodiment 3

[0040] Such as Figure 7 As shown, the brake disc cleaning device, the difference between this embodiment and the second embodiment is that: the support base 1 is provided with a water tank 17 for cleaning the cleaning belt 8, and the water tank 17 is provided with a cleaning roller 18 for cleaning the cleaning belt 8, and the cleaning roller 18 is connected with conveying roller 5 by gear 19, toothed chain 20.

[0041] During specific implementation, the drive motor is started, and the drive motor drives the rotating roller 6 to start rotating. The turning roller 6 is connected with other parts of the cleaning unit 2 through the turning belt 4, so the turning roller 6 drives the whole cleaning unit 2 to start running. When the cleaning belt 8 passes through the pressure roller 7 and moves toward the water tank 17, the cleaning belt 8 is in a relaxed state at this time. Due to gravity, the rubber side of the cleaning belt 8 faces downward and is on the outside of the cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com