Impeller for washing machine and washing machine using impeller

A technology of washing machine and pulsator, applied in the field of washing machine, which can solve the problems such as the load is not easy to turn over, the amount of clothing slippage is small, and the clothes are not easy to turn over, so as to achieve the effect of low cost, improved washing rate, and easy turning over

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

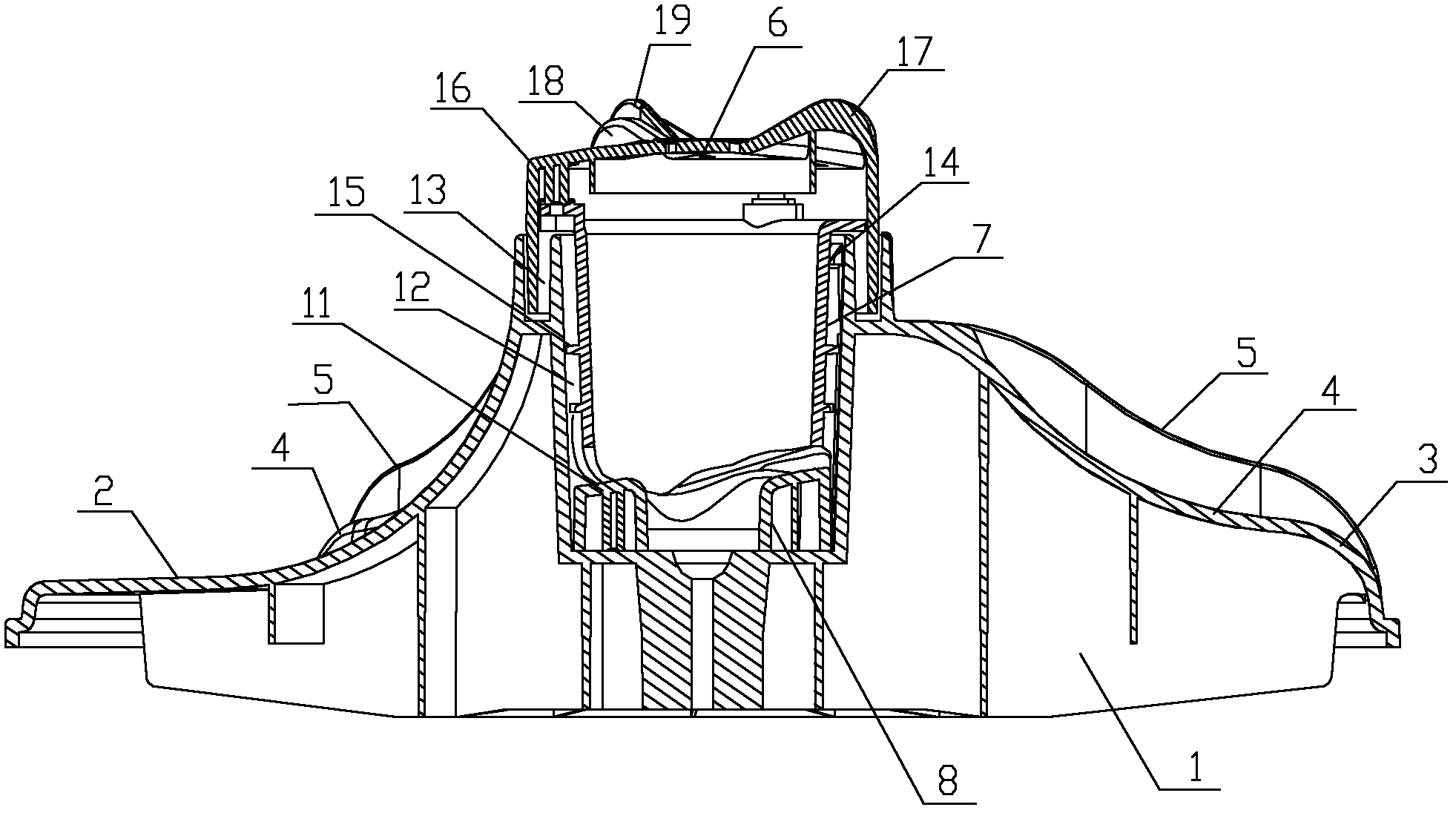

[0031] The pulsator washing machine commonly used in family life at present comprises a housing (not shown in the figure), on which a control panel and a door for taking and placing clothes are arranged on the surface of the housing, and a water tank for holding water is arranged in the housing. An outer cylinder (not shown in the figure) and an inner cylinder (not shown in the figure) for washing, wherein the outer cylinder is fixed and does not rotate, the inner cylinder is arranged on the inner side of the outer cylinder, and the inner cylinder is driven by a driving device (in the figure not shown) to drive the rotation, the wall of the inner cylinder has several openings for the passage of washing water, the bottom of the inner cylinder is provided with a pulsator, and the pulsator is driven by a driving device. A water inlet is arranged on the upper part of the outer cylinder for water intake in the washing and rinsing process, and a water outlet is arranged on the lower ...

Embodiment 2

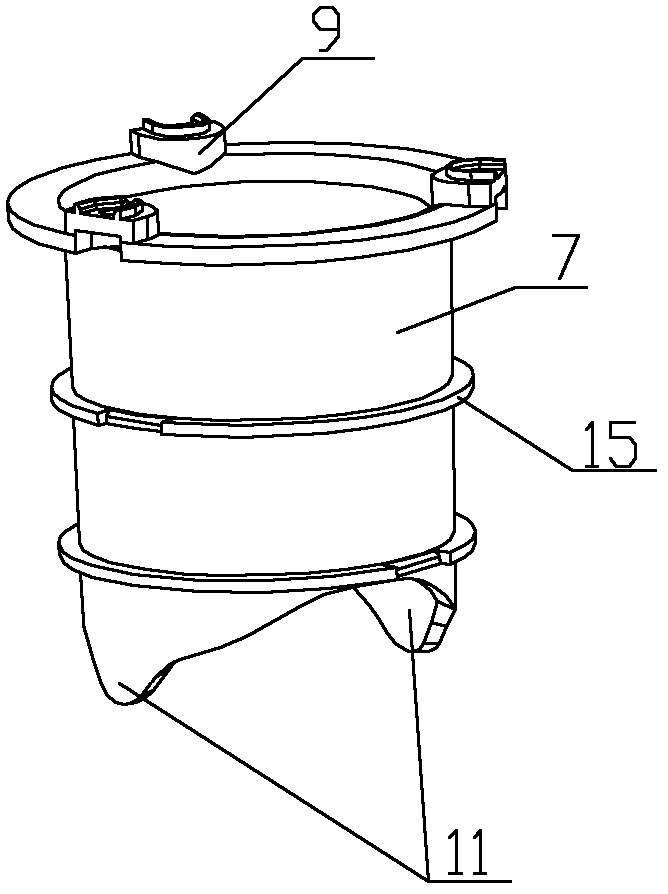

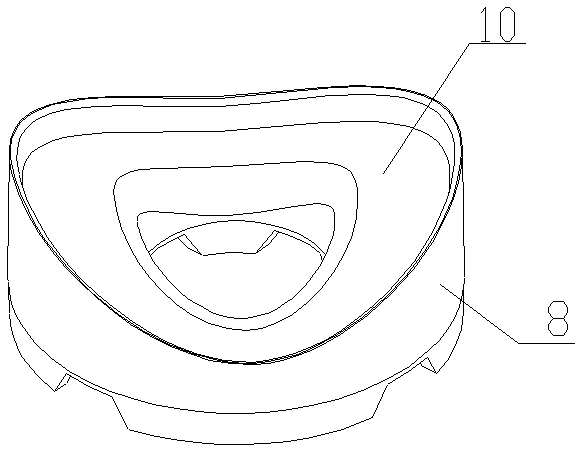

[0046] The difference from Embodiment 1 is that, as Figure 5 As shown, the top of the sliding chassis 8 has a sliding slope 20 . Such as Figure 4 As shown, there is a downward protruding cam 11 at the bottom of the impact bar 7, and the bottoms of the two cams 11 are in sliding contact with the sliding slope 20. When the impact bar 7 or the sliding chassis 8 rotates, the cam at the bottom of the impact bar 7 11 slides along the sliding slope 20, and at the same time, the impact rod 7 makes vertical reciprocating motion up and down under the action of the sliding slope 20, and then drives the small wave wheel 6 to make vertical reciprocating motion up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com