Machining method for eyeglass spring hinge strip material

A processing method and technology of spring feet, which are applied in the processing field of glasses spring feet, can solve the problems of inconvenient processing of glasses spring feet, and achieve the effects of good deburring effect, convenient use, and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0032] A kind of processing method of spectacle spring leg material, it is characterized in that, this processing method comprises the following steps: a, select metal plate material, select copper plate in this example; b, clean, carry out pickling to the stain of metal plate material, Pickling is an existing technology, and it is placed in a pickling tank to clean impurities such as oil stains; c, drying, using an existing dryer to dry; d, punching, using a punch to punch metal sheets Become the shape of spring foot bar material;

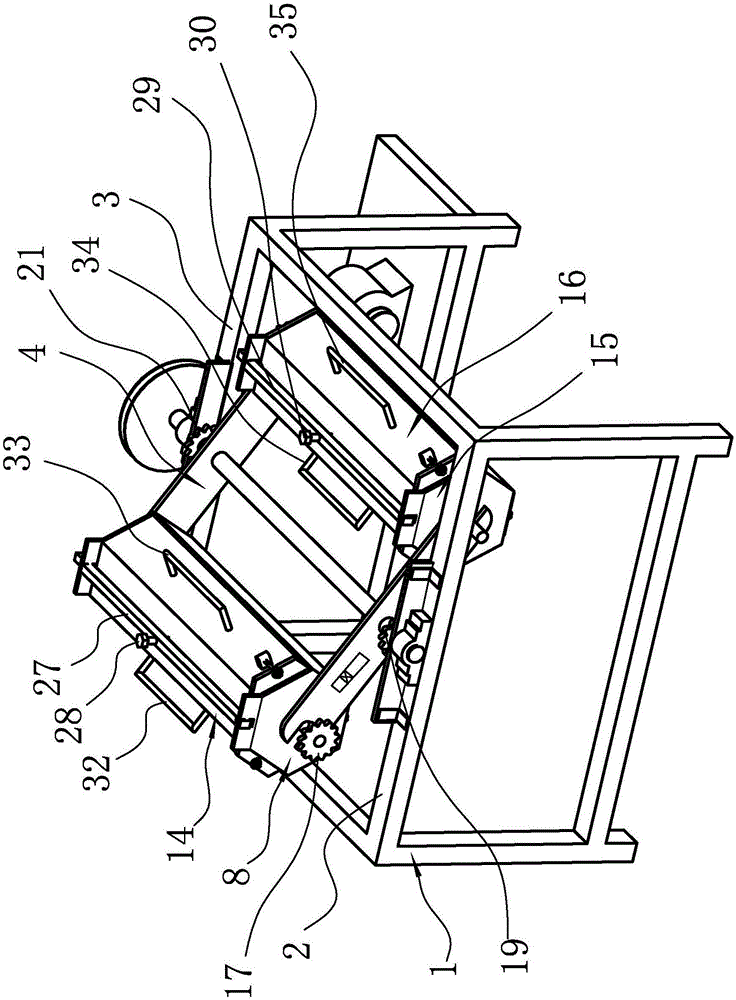

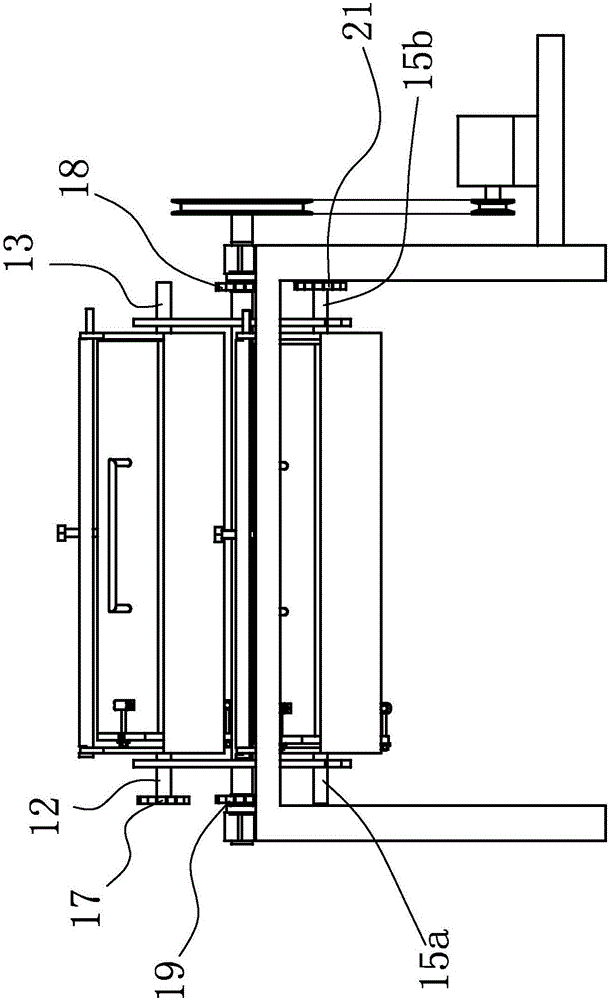

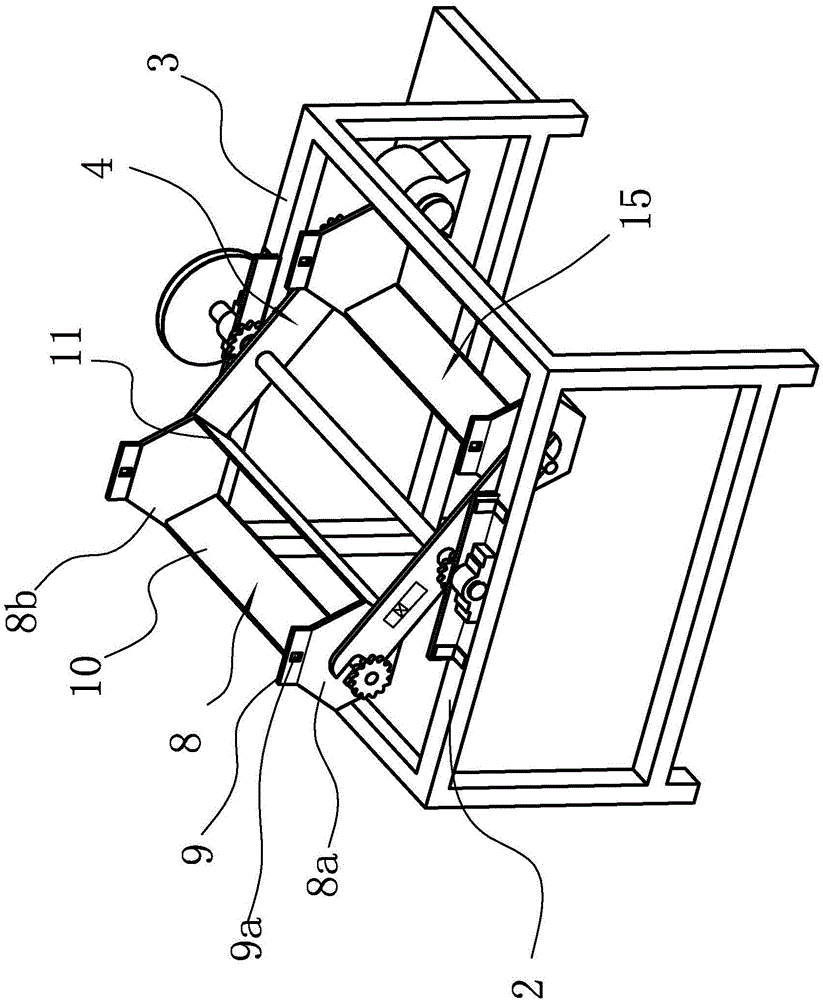

[0033] Such as figure 1 Shown in -8, a kind of improved rotary grinder comprises frame 1, and described frame 1 comprises left crossbeam 2 and right crossbeam 3, and left crossbeam 2 and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com