Wood plastic environment friendly ecological material and production technology thereof

An ecological material and environmental protection technology, applied in material design, production process of wood plastic environmental protection ecological material, wood plastic environmental protection ecological material field, can solve problems such as unfavorable environmental protection, loose account, harmful environment, etc., to reduce easy deformation defects , consistent quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A wood-plastic environmentally friendly ecological material, consisting of the following components by mass, 70 parts of plant fiber powder, the plant fiber is a combination of wood flour and grain flour, 30 parts of hot-melt plastic powder, and 5 parts of additives ; The auxiliary agent is composed of sodium bicarbonate of isocyanate, dibutyl phthalate, and zinc stecholate in a mass ratio of 1:1:1:1.

Embodiment 2

[0020] A wood-plastic environmental protection ecological material, consisting of the following components by mass, 65 parts of plant fiber, the plant fiber is a combination of wood flour, grain flour and straw powder, 40 parts of hot-melt plastic, auxiliary agent 8 parts; the auxiliary agent is composed of cumene peroxide, dioctyl phthalate, ethylene bis fatty acid amide and azodicarbonamide in a mass ratio of 1:1.5:1:1.

Embodiment 3

[0022] A wood-plastic environmental protection ecological material, consisting of the following components by mass, 60 parts of plant fiber powder, the plant fiber is bamboo powder, 35 parts of hot-melt plastic powder, 3 parts of auxiliary agent; The agent is composed of silane coupling agent, dibutyl phthalate, stearic acid or lead stearate and azodicarbonamide in a mass ratio of 1:1.5:2:1.

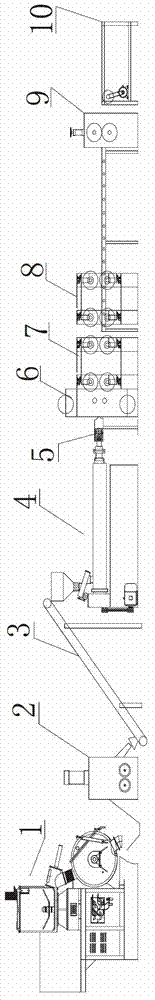

[0023] The preparation method of wood-plastic environment-friendly ecological materials in Examples 1 to 3 is: including the following steps in sequence: 1) Weighing the following components by mass, 60-70 parts of plant fiber, 30-40 parts of hot-melt plastic 3 to 8 parts of coupling agent and grafting aid; 2) Pour the plant fiber powder into the mixing unit for coupling and dehydration, then add plastic powder and additives for pre-plasticization and mixing to obtain a prepolymer; 3 ) Add the prepolymer into the internal mixer for full plasticization and homogenization, add the prepolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com