Candy dicing and packing all-in-one machine

An all-in-one machine and block cutting technology, which is applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of reduced production efficiency, low production efficiency, and increased production costs, and achieves avoidance of adhesion and accumulation, high production efficiency, and structural integrity. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

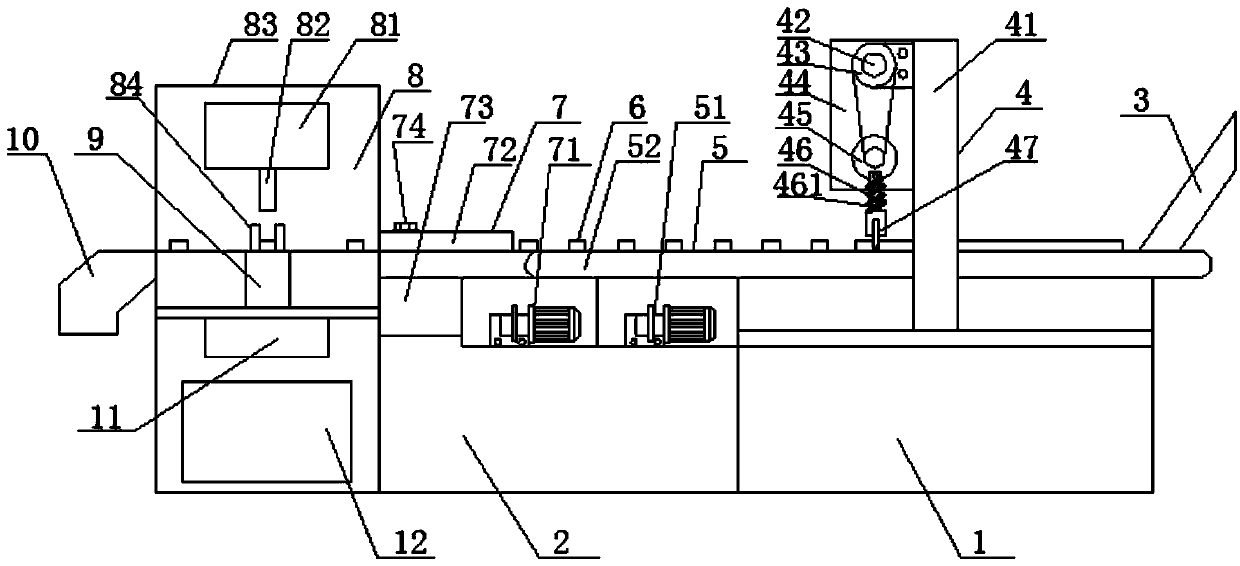

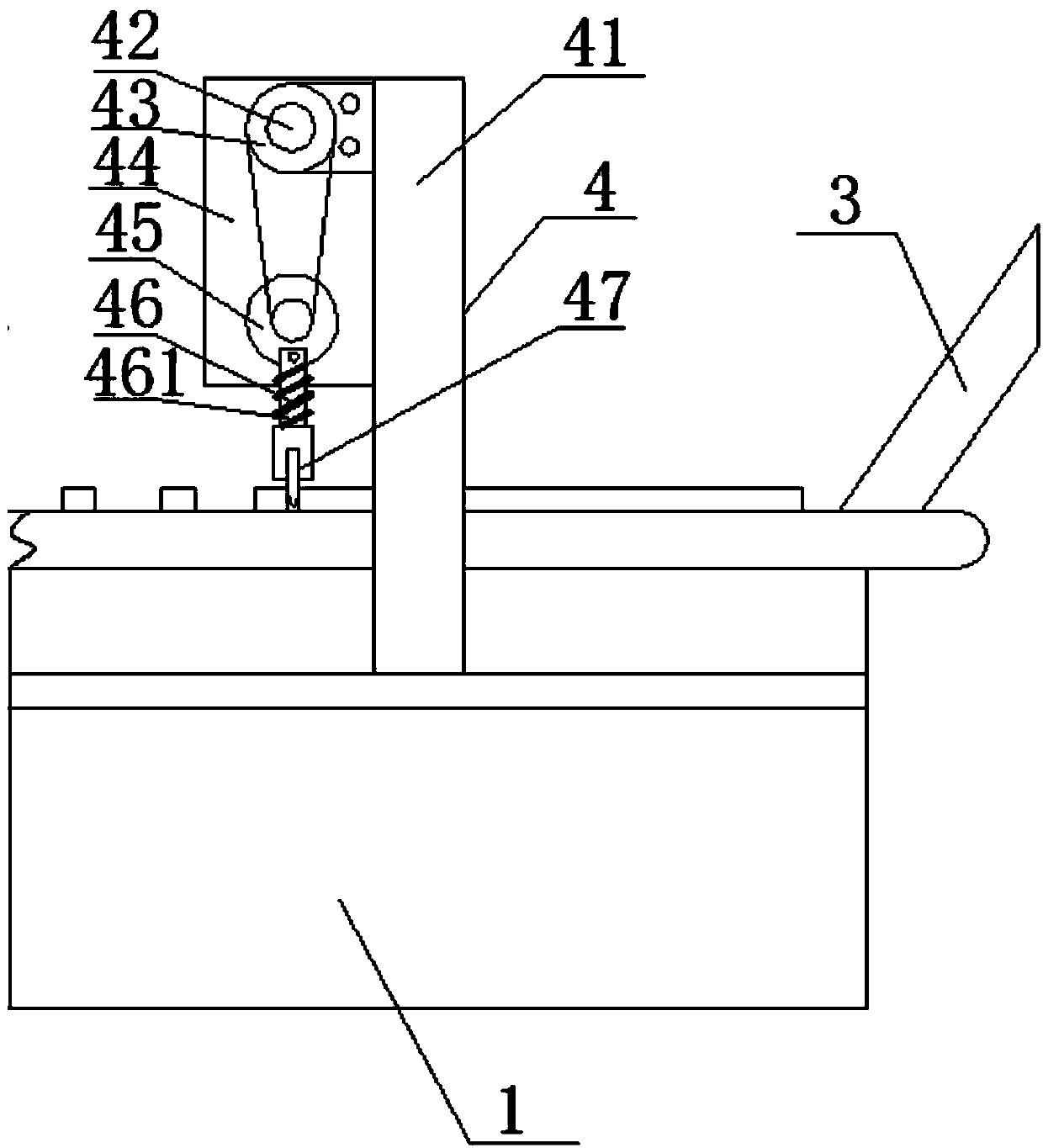

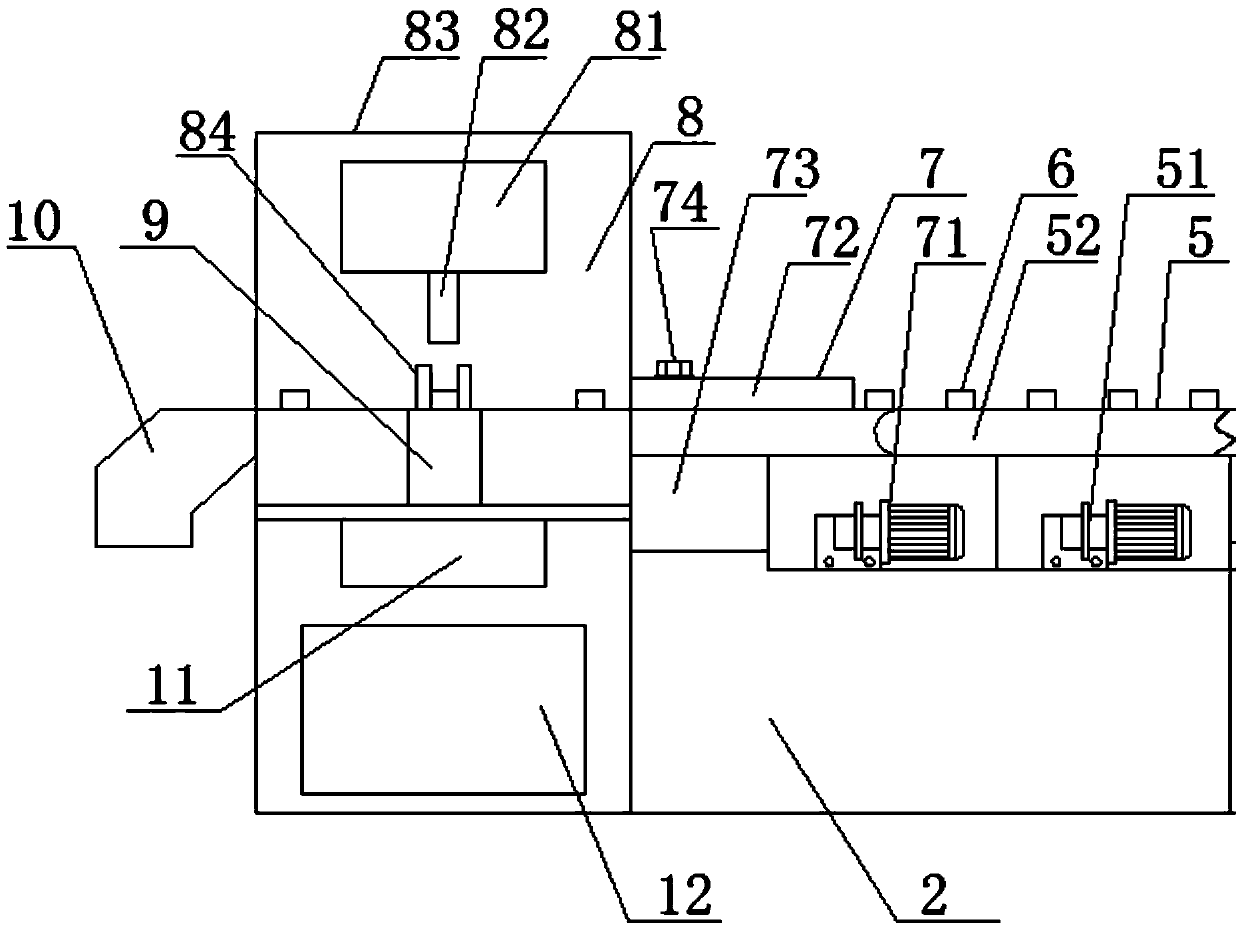

[0023] refer to Figure 1 to Figure 5 , the present invention includes a dicing workbench 1 and a packaging workbench 2, the dicing workbench 1 and the packaging workbench 2 are connected and installed, a feeding plate 3 and a dicing mechanism 4 are installed on the dicing workbench 1, the described Cutting mechanism 4 comprises mounting post 41, cutting motor 42, mounting block 44, belt pulley 43, eccentric wheel 45, ejector rod 46, cutter 47; Mechanism 7, sugar wrapping mechanism 8, sugar delivery mechanism 5 includes sugar delivery motor 51 and conveyor belt 52, sugar sorting mechanism 7 includes sugar sorting motor 71, sugar dividing rod 72 and temperature controller 73, sugar wrapping mechanism 8 includes electrical control system 81 , sugar pressing bar 82, packaging table 83, first bag sugar bar 84, second bag sugar bar 85, third bag sugar bar 86, fourth bag sugar bar 87; The paper feeding device 9 corresponds to the bottom of the sugar wrapping mechanism 8, and the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com