Rubber strip stock cutter

A cutting machine and strip-shaped technology, which is applied in metal processing and other directions, can solve the problems of increasing manufacturing cost, consuming large labor force, affecting production efficiency, etc., and achieve the effect of improving production efficiency and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

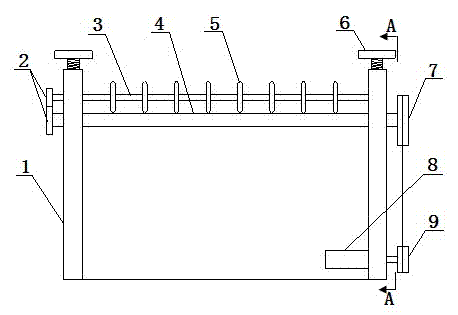

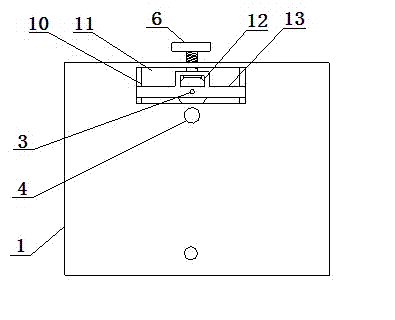

[0013] Such as figure 1 and figure 2 As shown, the elongated rubber cutting machine of the present invention includes a frame 1, and the top of the frame 1 has a blade shaft 3 and a roller 4 arranged in a parallel shape successively from top to bottom, and the blade shaft 3 and the roller 4 Both ends are rotatably fixed on the frame 1. A plurality of circular blades 5 with outer cutting edges are uniformly distributed on the blade shaft 3 , the circular blades 5 are coaxial with the blade shaft 3 , and the circular blades 5 and the roller shaft 4 are in a virtual contact state. Both ends of the roller 4 protrude from the outside of the frame 1, and a gear 2 is fixed on one protruding end, and a driven wheel 7 is fixed on the other protruding end. One end corresponding to the gear end of the blade shaft 3 and the roller shaft 4 also protrudes from the outside of the frame 1, and the section of the blade shaft 3 is also fixed with a gear 2, the gear 2 of the blade shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com