Automatic cutoff device of filter cotton of aquarium

A technology of automatic cutting and filtering cotton, applied in metal processing and other directions, can solve the problems of inconsistent cutting length, long cutting time, poor efficiency, etc., and achieve the effect of good cutting surface quality, low cost and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will now be further described with reference to the accompanying drawings.

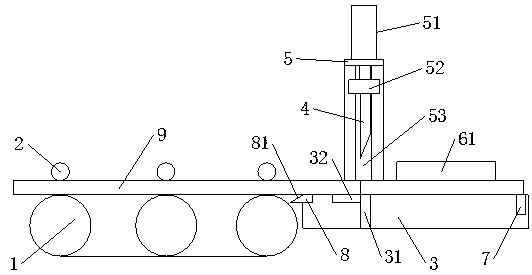

[0024] like figure 1 As shown, the aquarium filter cotton automatic cutting device includes a conveyor belt 1, a cutting knife 4, a lifting device, a pushing device and a positioning device; a roller 2 is installed above the conveyor belt 1, and the roller 2 presses the filter cotton 9 on the conveyor belt. 1, one end of the conveyor belt 1 is provided with a cutting plate 3, the cutting plate 3 is provided with a cutting groove 31, the cutting groove 31 is facing the cutting knife 4, the cutting knife 4 is located above the cutting plate 3, and the cutting knife 4 is installed in the lift. On the device, the positioning device is installed at one end of the cutting plate 3 and is far away from the cutting groove 31. The positioning device controls the cutting length of the filter cotton 9 by controlling the start and stop of the conveyor belt 1; The device pushes the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com