Circuit board production pin machining device

A processing device and circuit board technology, which is applied in the field of circuit board processing, can solve the problems of high frequency of cutting and moving raw materials, inability to ensure stable placement of raw materials, and consuming a lot of manpower and time, so as to achieve ideal results in efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

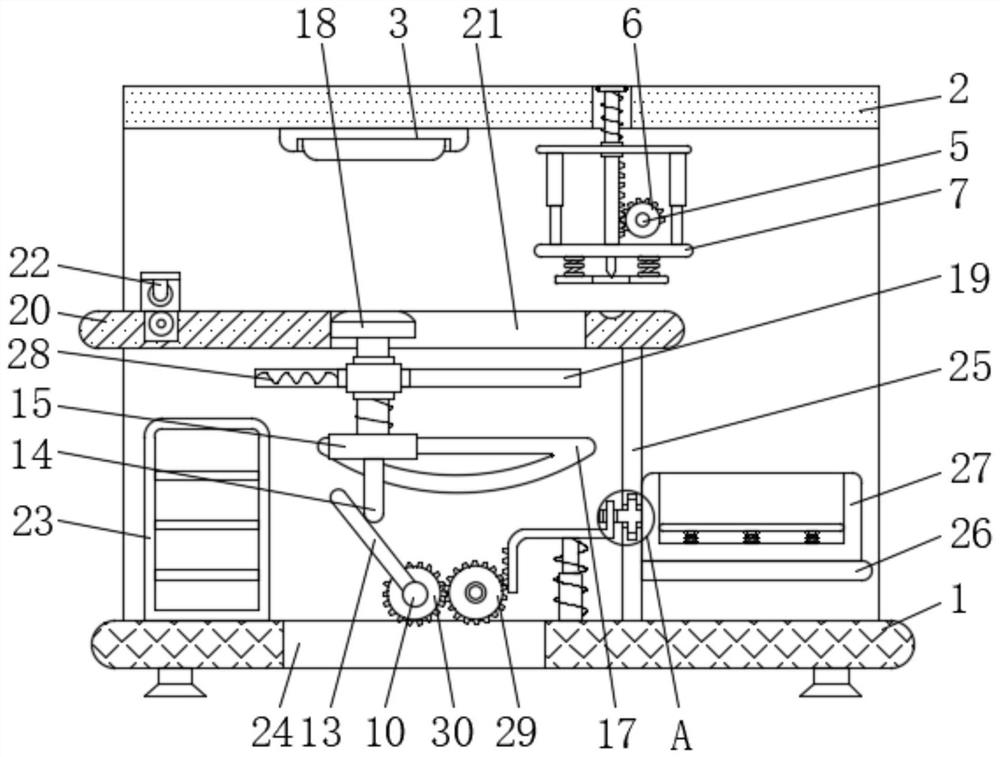

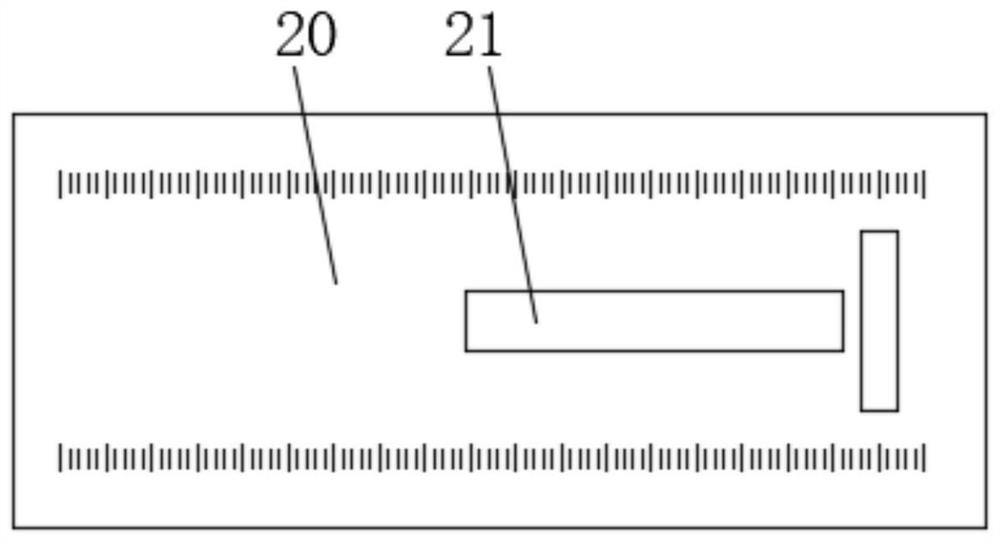

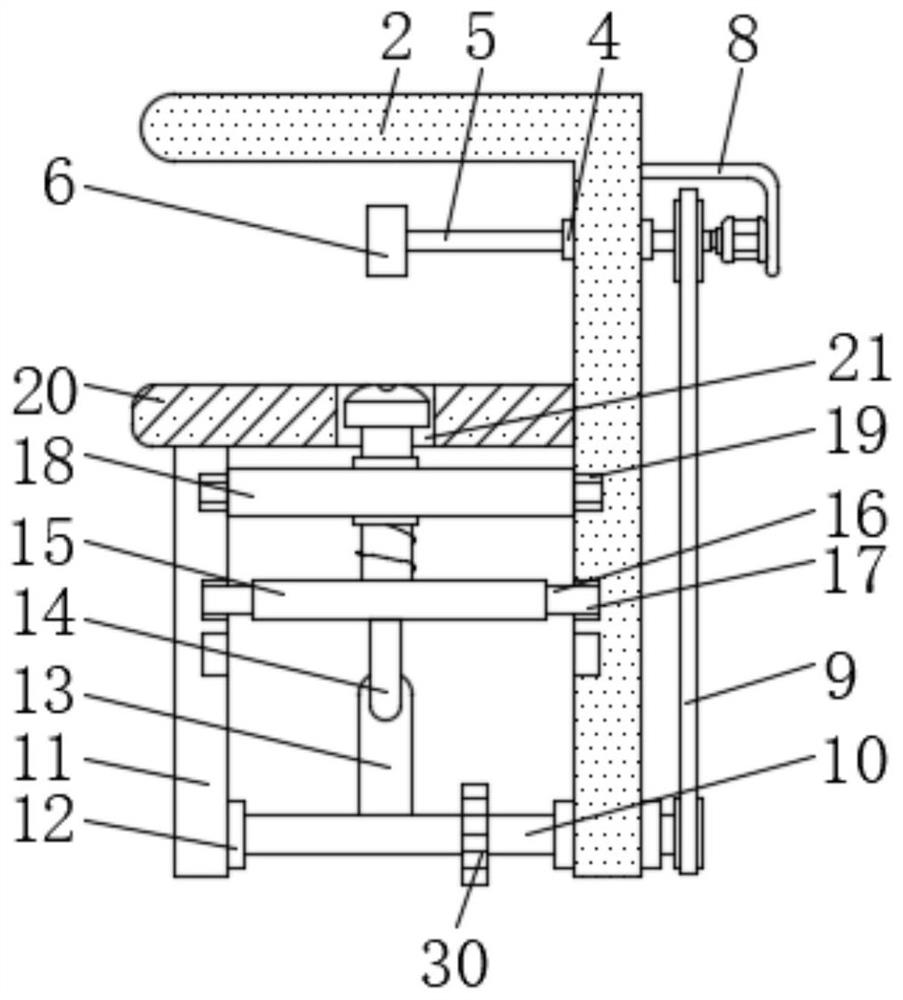

[0037] Such as Figure 1-9As shown, the present invention provides a technical solution: a pin processing device for circuit board production, including a base plate 1, a support frame 2 is provided on the upper surface of the base plate 1, and a cutting assembly mechanism 7 is provided on the back of the inner wall of the support frame 2. The component mechanism 7 meshes with the half gear 6, the back of the half gear 6 is clamped with the first rotating shaft 5, and the outer surface of the first rotating shaft 5 is provided with the first bearing 4, by setting the first bearing 4 and the first rotating shaft 5, it is ensured that the half gear The smooth and stable rotation of the gear 6 can ensure the stable meshing process between the gear bar 703 and the half gear 6 , the first bearing 4 is clamped on the back of the support frame 2 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com