Laser cutting machine of board or strip

A laser cutting machine and strip technology, applied in the direction of laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of limiting the cutting accuracy and inaccuracy of laser cutting machines, and achieve the effect of controlling inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

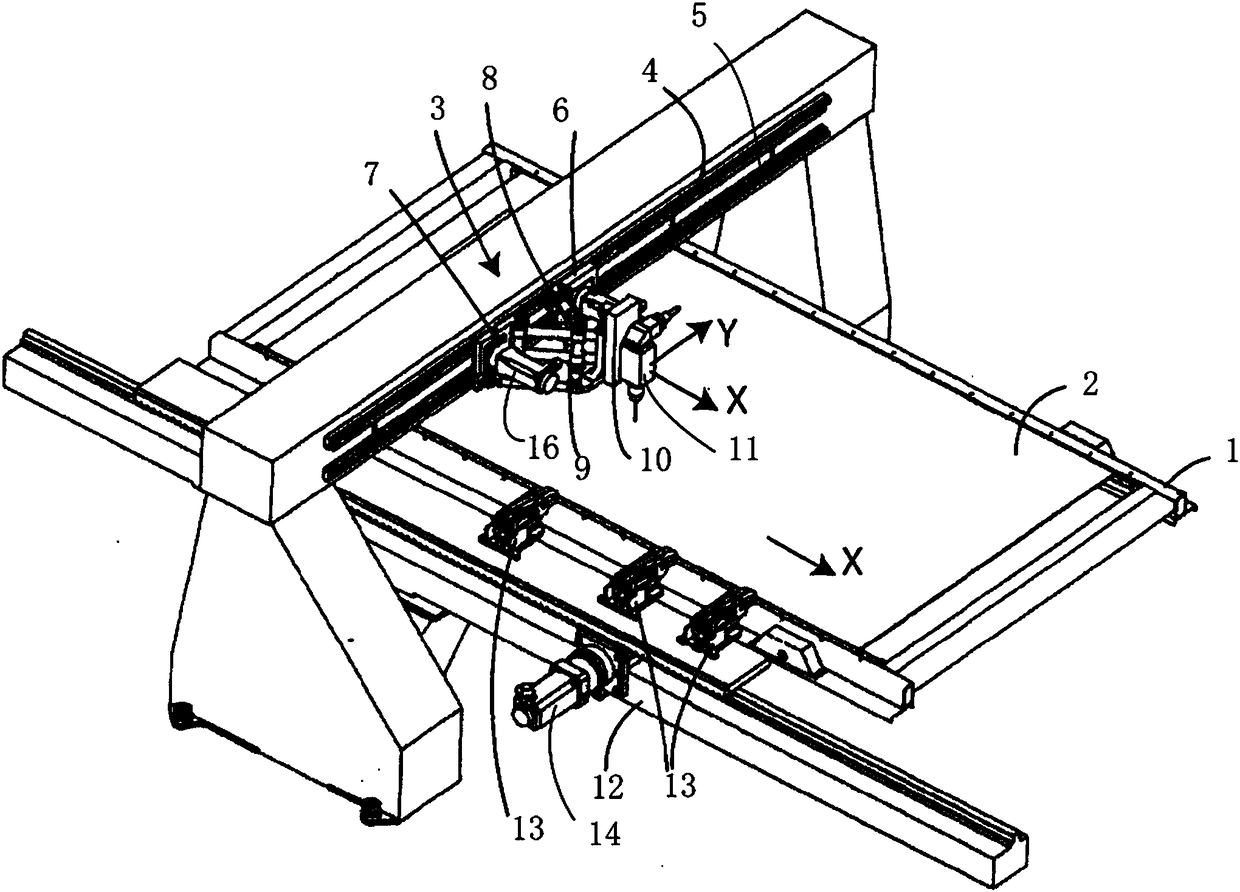

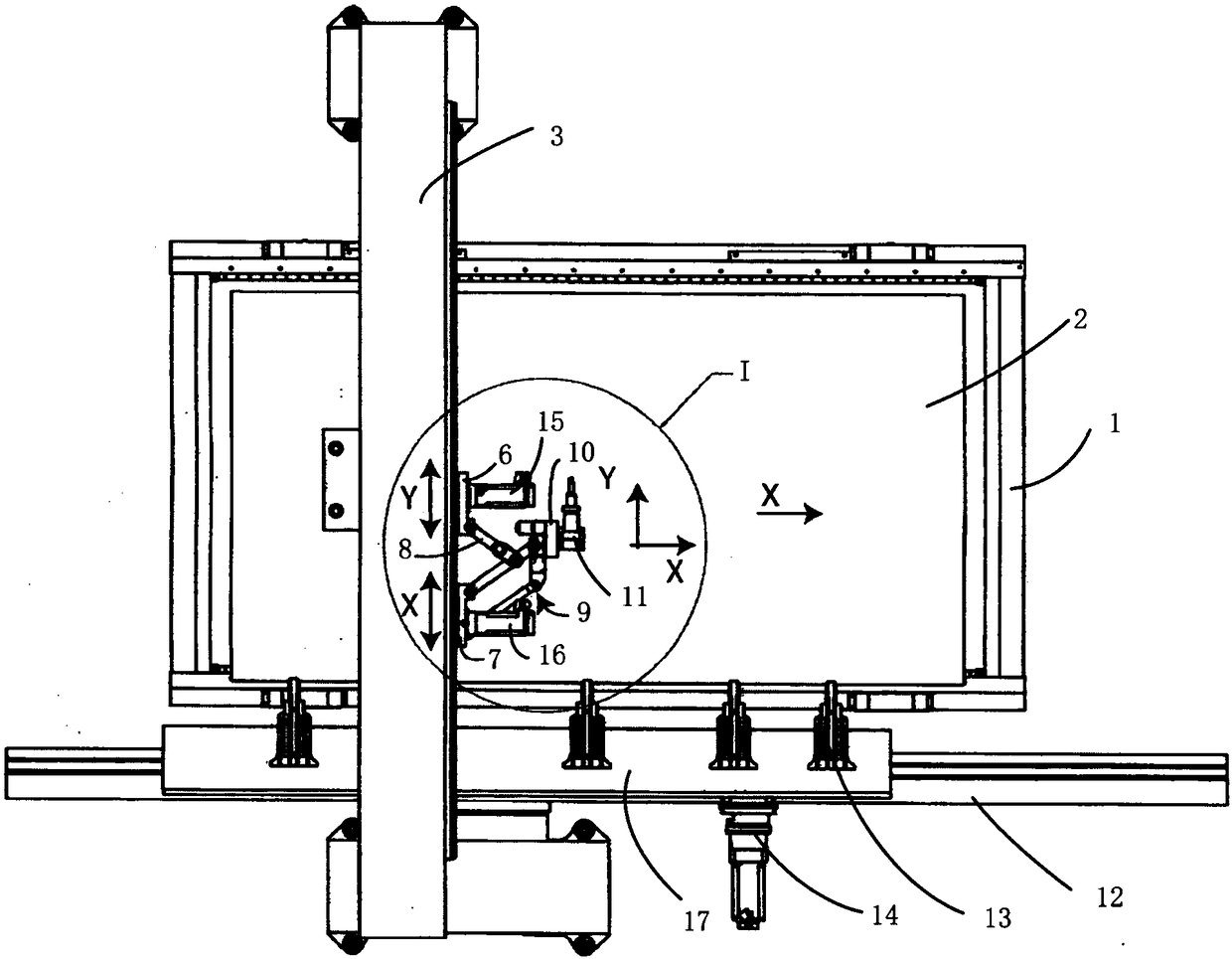

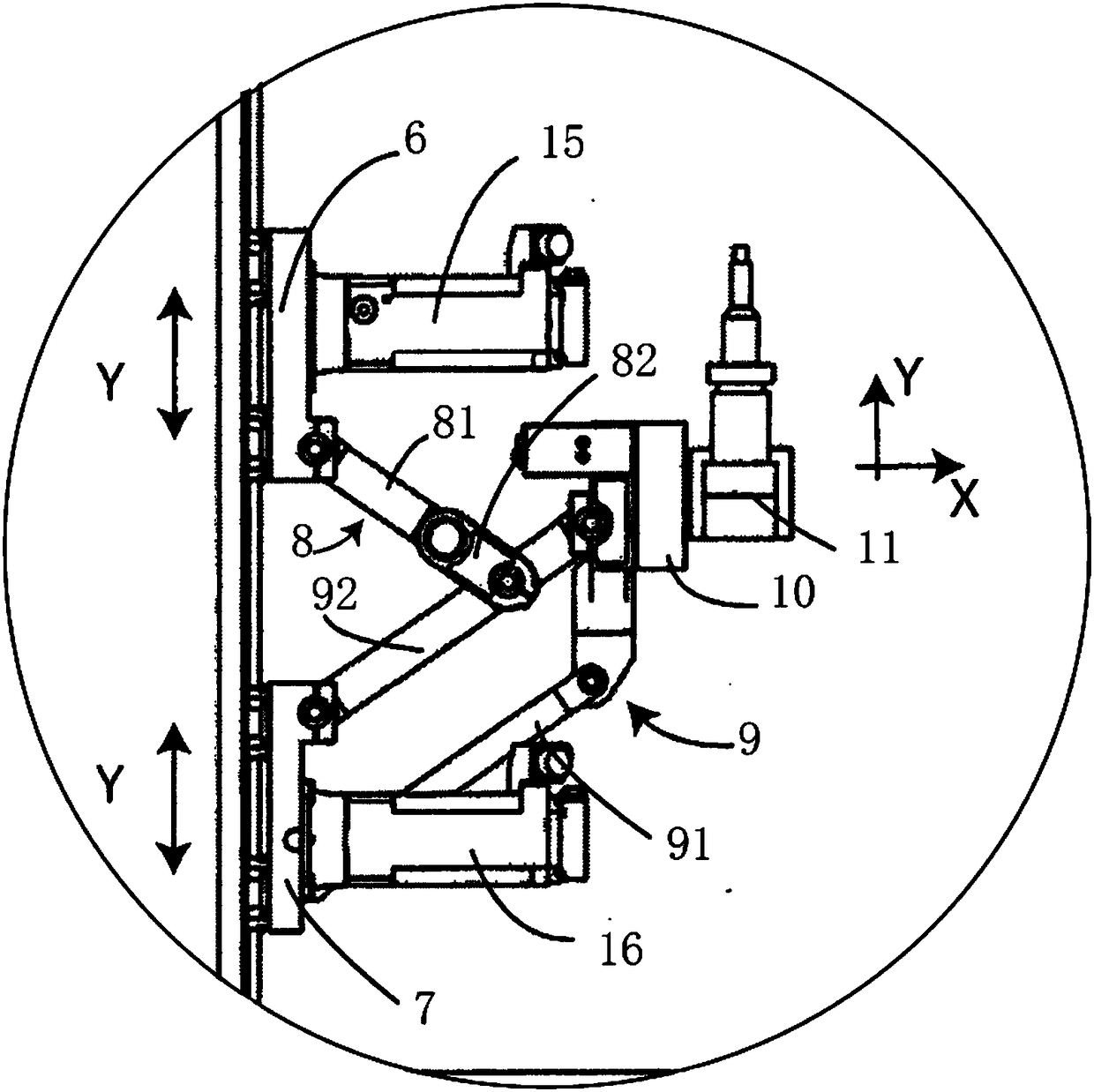

[0026] like figure 1 , 2 , 3, a laser cutting machine for a plate 2 or a strip, including a worktable 1 and a laser head 11, the laser cutting machine in this embodiment is used to cut discrete plates 2 or strips, the laser cutting machine also It includes a gantry 3 across the top of the worktable 1. The gantry 3 has a transversely extending beam on which a transverse guide rail 4 is arranged. The plate 2 or strip can be pulled on the worktable 1 to move horizontally and vertically. , in this embodiment, side supports 12 are provided on the side of the worktop 1, and longitudinal guide rails are provided on the side supports 12, and a longitudinal moving plate 17 is installed longitudinally on the longitudinal guide rails, and the longitudinal moving plate 17 is fixed There are several traction fixtures 13 for clamping the plate 2 or the edge of the strip. In the present embodiment, the traction fixtures 13 are four sets. Just hold the edge of the plate 2. The longitudinal...

Embodiment 2

[0035] like Figure 4 As shown, the structure in this embodiment is the same as the structure in Embodiment 1, except that the sheet 2 or strip cut in this embodiment is a coil, such as Figure 4 As shown, the coil is placed on the unwinder and pulled horizontally by the tractor to move the sheet 2 or strip longitudinally over the work surface 1 . Both the unwinder and the tractor are the current conventional technologies, and the tractor can be driven by a servo motor to precisely control the unwinding speed of the coil.

[0036] The actuators such as cylinders, servo motors, and rack-and-pinion mechanisms mentioned in this embodiment are all current conventional technologies. The specific structure and principle and other designs of the cylinder, motor and other transmission mechanisms are disclosed in detail in the book, which belongs to the prior art, and its structure is clear and clear. The Modern Practical Pneumatic Technology No. 1 published by the Machinery Industry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com