Side suction thread shearing device of industrial sewing machine

An industrial sewing machine and thread trimming technology, which is applied in the sewing machine to cut off the thread mechanism, sewing machine components, sewing equipment, etc., can solve problems such as incoherent work and affecting production efficiency, and achieve simple operation, simple structure, and avoid incoherent work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

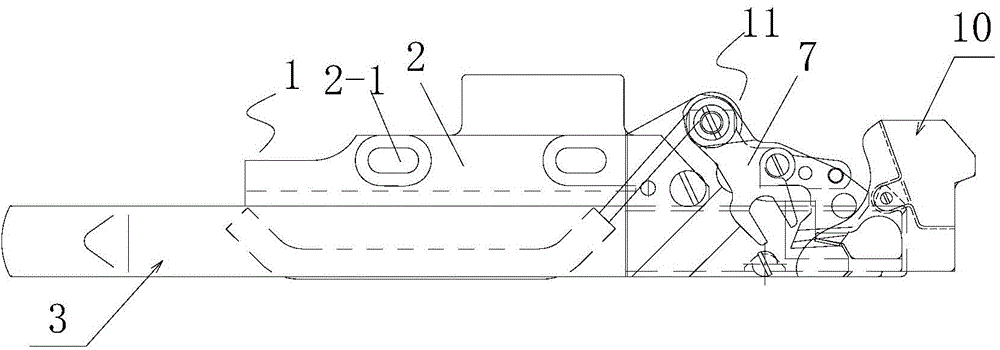

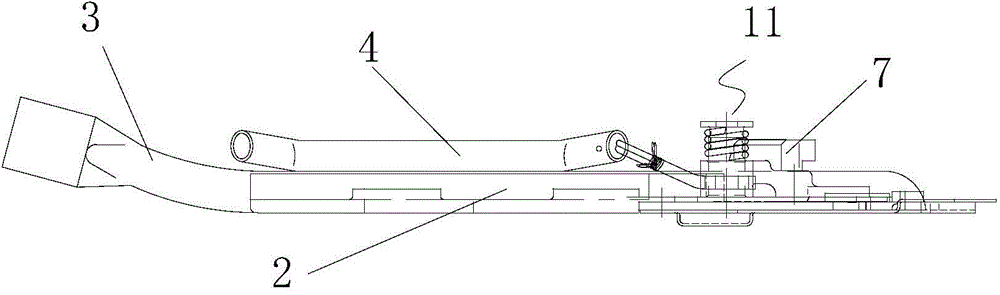

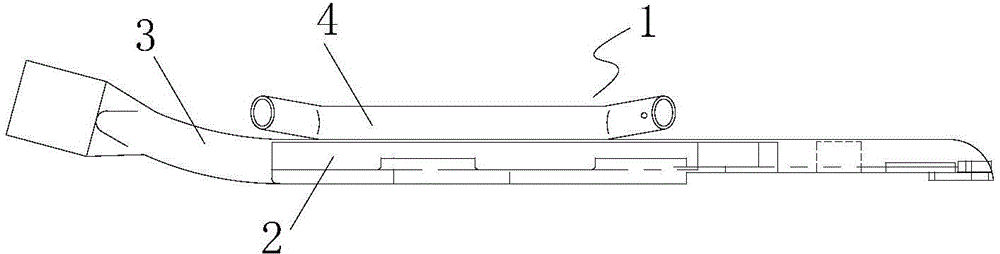

[0025] See the accompanying drawings for details. This embodiment provides a side suction thread trimming device for an industrial sewing machine, including a side suction device body 1, a support plate 2, a thread suction head pipe 3, an oil suction pipe 4, a moving knife 5, a fixed knife 6, and a control lever 7. The triangular fixing block 8 and the semicircular fixing block 9 play a positioning role. The oil suction pipe and the thread suction head pipe are fixedly connected to form an integral structure, and the thread suction head pipe, the oil suction pipe and the support plate are fixedly connected to form an integral side suction device body , the fixed knife is fixedly connected to the support plate, the movable knife is fixedly connected to the control lever to form a moving knife linkage mechanism 11, the control lever is slidably connected to the shaft sleeve 12, and the shaft sleeve is connected to the bracket. The support plate is provided with two circular hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com