Sawing gearbox

A gear box and sawing technology, applied in metal sawing equipment, belts/chains/gears, sawing machines, etc., can solve the problems of reduced saw blade cutting efficiency and cutting accuracy, reduced gear service life, and unstable gear transmission. , to achieve the effect of small vibration, protection of the output shaft, and improvement of sawing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

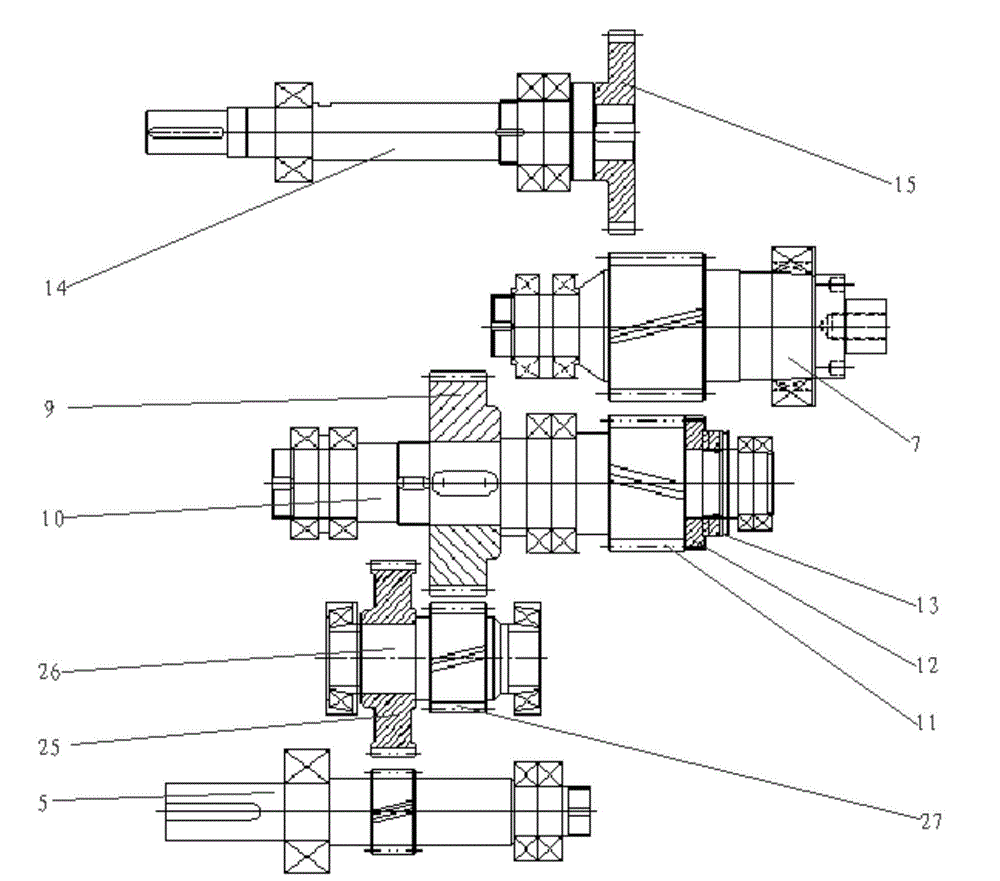

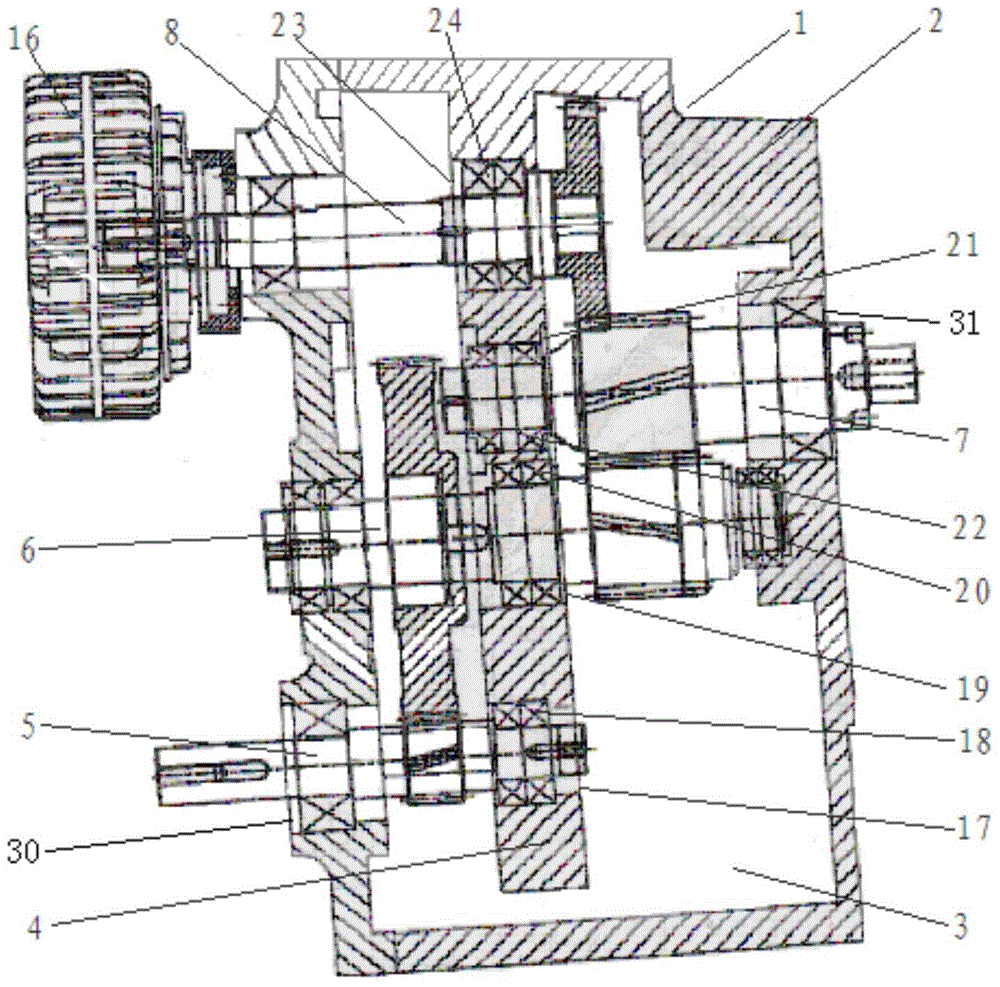

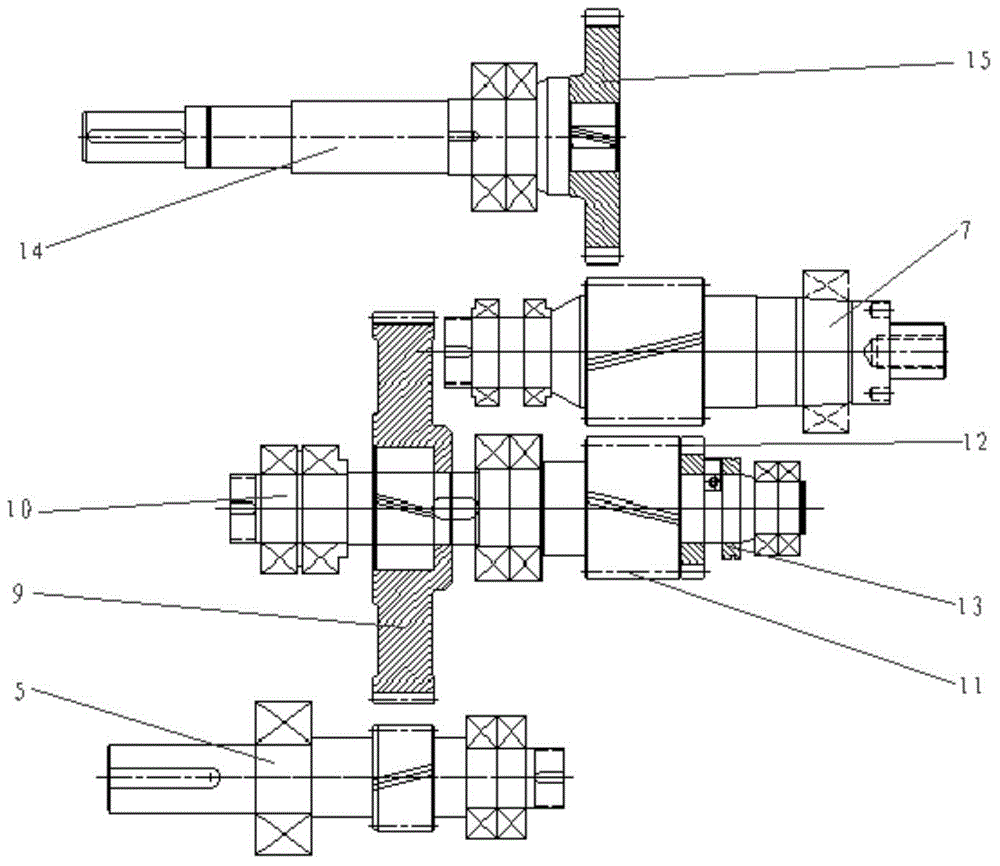

[0027] Such as Figure 1-3 As shown, the sawing gear box according to Embodiment 1 of the present invention includes a box body 2, a working chamber 3 for gear work is provided inside the box body 2, and a fixing plate 4 is provided in the middle of the working chamber 3 , the bottom of the fixed plate 4 is provided with a functional hole 17 for the input gear shaft 5 to pass through, the functional hole 17 is provided with a bearing 18 that matches the input gear shaft 5, and the functional hole 17 The position corresponding to the intermediate gear shaft 10 above is provided with a functional hole 2 19 for the intermediate gear shaft 10 to pass through. The functional hole 2 19 is provided with a bearing 20 matching with the intermediate gear shaft 10. The functional hole 2 19 The position corresponding to the output gear shaft 7 is provided with a functional hole 3 21 for the output gear shaft 7 to pass through. The functional hole 3 21 is provided with a bearing 3 22 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com