Steel plate punching device capable of automatically replacing punch

An automatic replacement and punching device technology, applied in the field of stamping machinery, can solve the problems of high stamping cost, time-consuming and labor-intensive, and delayed production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

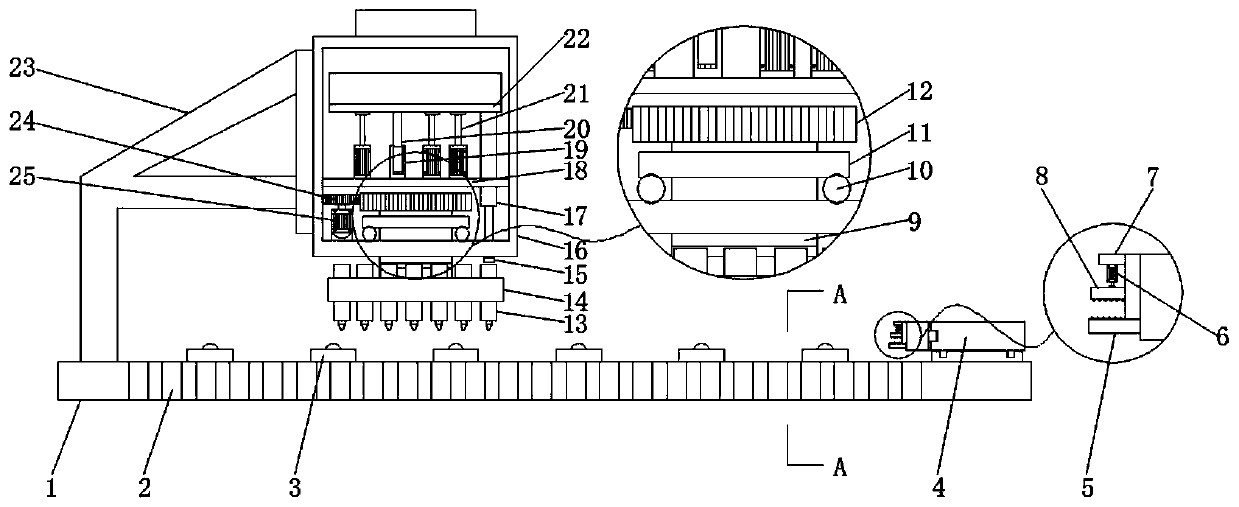

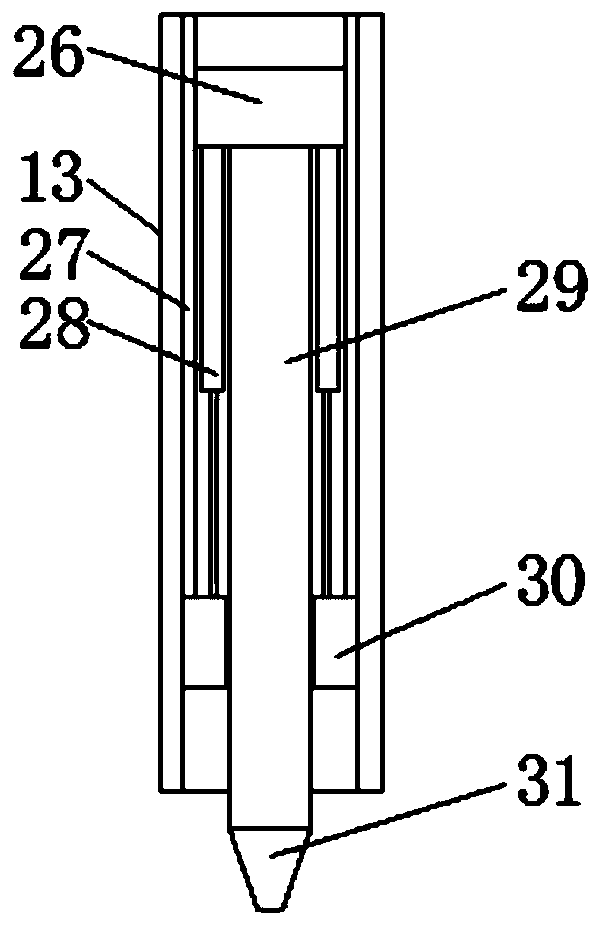

[0028] Embodiment one, with reference to figure 1 , image 3 with Figure 4 , a steel plate punching device that automatically replaces the punch, including a mounting table 1 and a casing 16, one end of the top surface of the mounting table 1 is fixedly installed with the organic casing 16 through a bracket 23, and the bottom surface of the casing 16 is connected with a rotating shaft 9 for rotation. , and the bottom surface of the rotating shaft 9 is welded with a turntable 14, the turntable 14 is a disc-shaped structure, the surface of the turntable 14 is fixedly connected with a sleeve 13, and the inside of the sleeve 13 is welded with a track 27, and the inside of the sleeve 13 is slidably connected with a slider 26. The slider 26 is slidingly connected with the track 27. The track 27 provides a guide for the slider 26 to prevent the slider 26 from shaking, and the bottom surface of the slider 26 is connected with a punch 31 through a punch rod 29, wherein the sleeve 13 ...

Embodiment 2

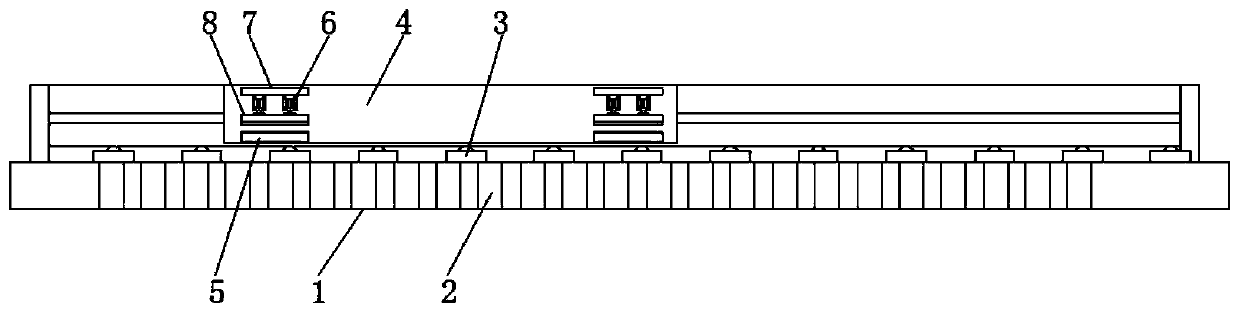

[0029] Embodiment two, refer to figure 2 , Figure 5 with Image 6, the other end of the top surface of the installation table 1 is installed with a biaxial slide 4, and the bottom surface of the side wall of the sliding end of the biaxial slide 4 is fixedly installed with a bottom splint 5, and the top surface of the side wall of the biaxial slide 4 corresponds to the bottom splint 5 position is welded with fixed plate 7, the bottom surface of fixed plate 7 is connected with upper splint 8 through hydraulic cylinder 6, two upper splint 8 and bottom splint 5 are provided, which is convenient for stably clamping the steel plate, and the top surface of installation platform 1 is fixedly connected with ball support Seat 3, wherein the ball support seat 3 includes a ball seat 301 and a first ball 302, and the first ball 302 is located inside the ball seat 301 and is rollingly connected with the ball seat 301, the top surface of the first ball 302 and the top surface of the botto...

Embodiment 3

[0030] Embodiment three, refer to figure 1 , the bottom surface of the top plate 22 is located between the cylinders 21 and is fixedly connected with a slide bar 20, the top surface of the mounting plate 18 is fixedly installed with a guide sleeve 19 corresponding to the position of the slide bar 20, the slide bar 20 is inserted into the guide sleeve 19 and is slidably connected with the guide sleeve 19, The slide bar 20 vertically moves up and down along the guide sleeve 19 to provide guidance for the top plate 22 and prevent the top plate 22 from shaking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com