Molding method for trailing arm beam of rear axle bracket assembly of automobile

A bracket assembly and forming method technology, applied in the direction of forming tools, perforating tools, feeding devices, etc., can solve the problems of unsatisfactory mass production, difficult quality assurance, and low production efficiency, so as to save laser equipment and production The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

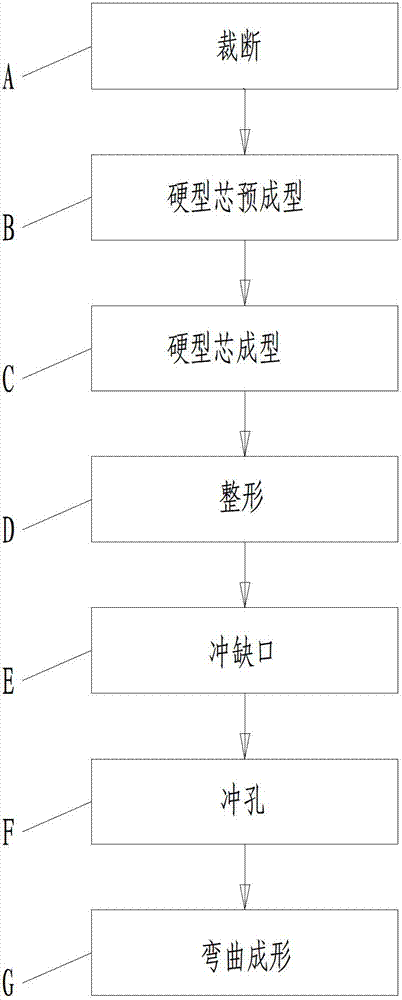

[0079] A method for forming a trailing arm beam of an automobile rear axle support assembly, the method comprises the following steps (see figure 1 shown in the flowchart):

[0080] A. Cutting: Use cutting die 1 on the punching machine to cut the raw material tube into a fixed-length rough round tube 2;

[0081] B. Hard core preforming: using a hard core preforming die 3 on a hydraulic press to stamp the blank round tube 2 at one time into a preformed tube 4 with a straight round tube at one end and an arc-shaped round tube at the other end;

[0082] C. Hard core preforming: continue to use the hard core forming die 5 on the hydraulic press to punch the preformed tube 4 into a flat tube with an inclined straight tube at one end, a horizontal straight flat tube at one end, and a multi-section curved flat tube with variable cross-section in the middle. Rectangular hollow tube with variable cross-section 6 .

[0083] D. Reshaping: Reshape the variable-section rectangular hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com