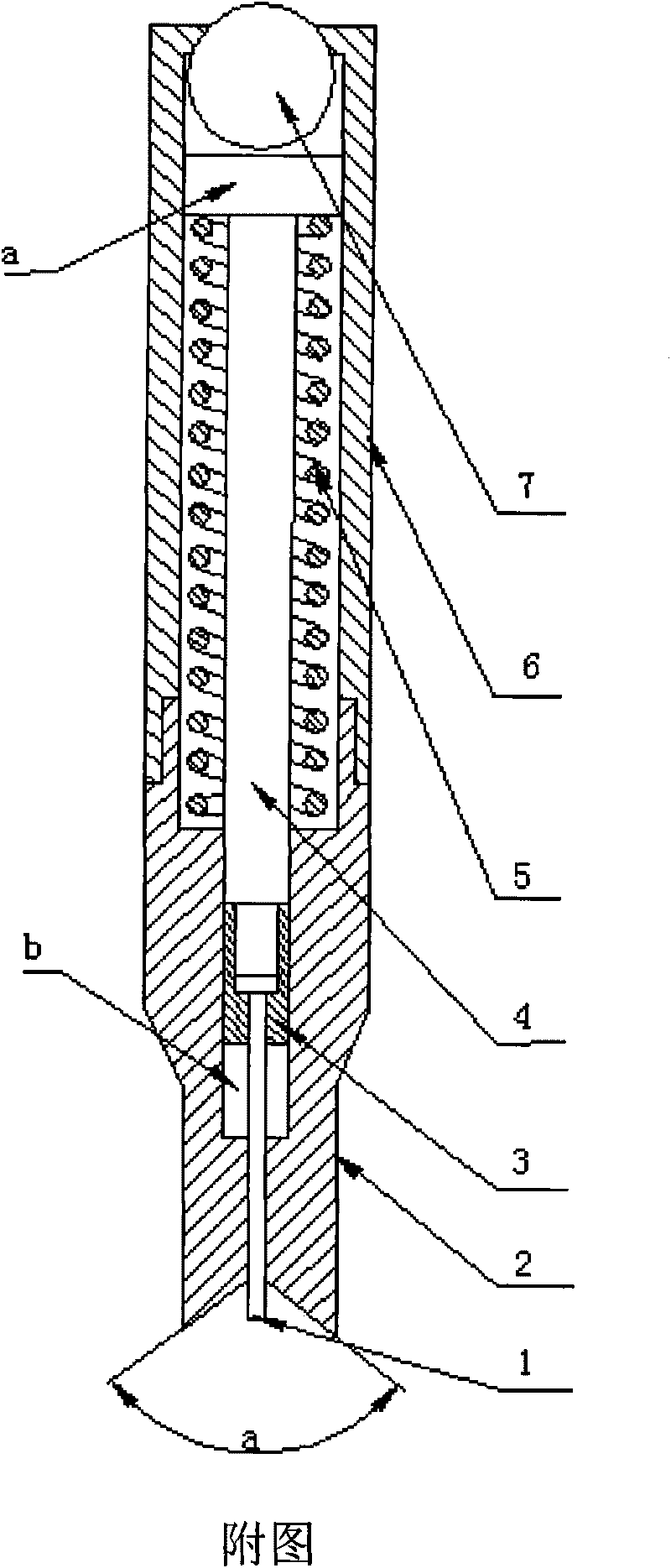

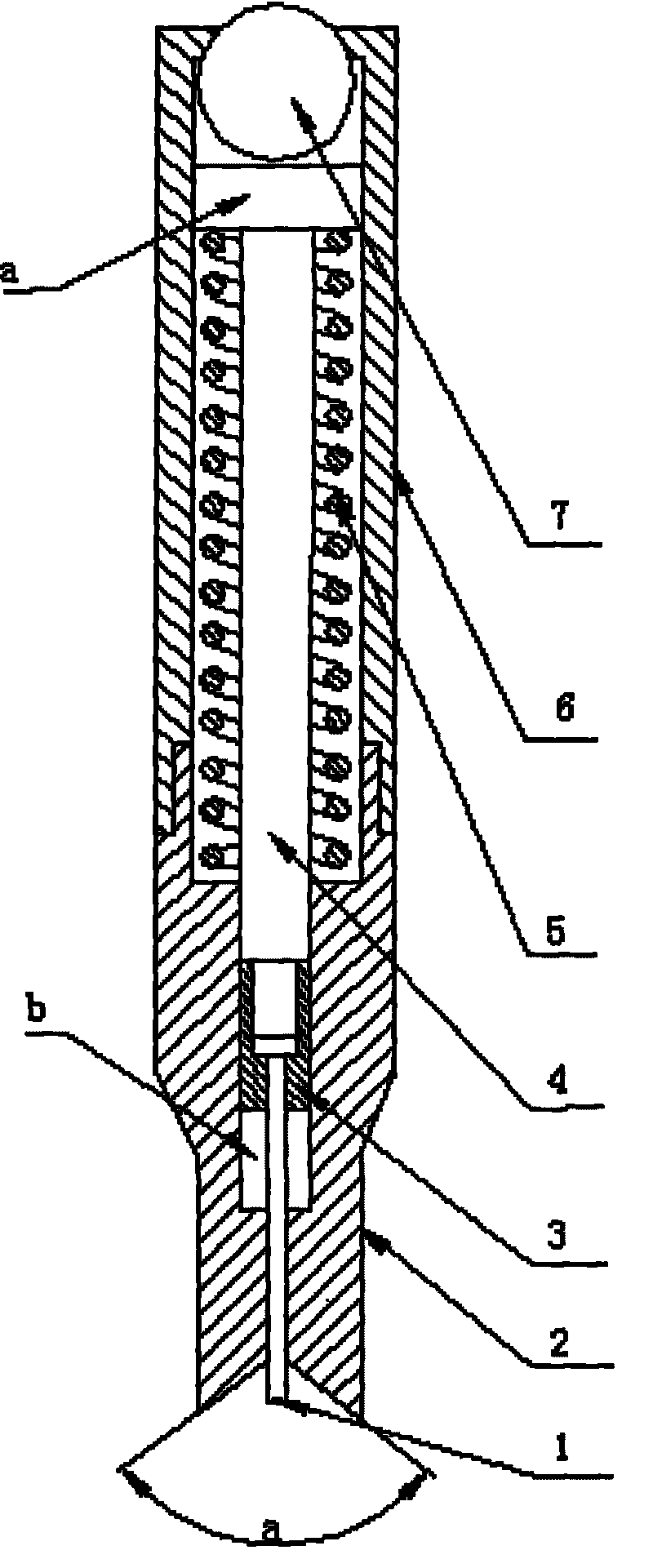

Novel wall tube punching tool

A wall tube and punching technology, which is applied in the field of new wall tube punching tools, can solve problems such as limited use conditions, poor punching quality, and sags in the hole, and achieves convenient use, good punching quality, and punching high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Put the punch (1) into the hole of the guide post (3), at the same time screw the outer thread of the lower end of the guide rod (4) into the inner thread of the guide post (3), and at the same time fix the punch pin (1) . Then steel ball (7) is packed in the endoporus of upper sleeve (6), packs into the assembly of punch (1), guide post (3) guide bar (4) that has been assembled simultaneously. After putting the spring (5) on the assembly of the punch (1), guide post (3) and guide rod (4), connect the upper sleeve (6) and the lower positioning sleeve (2) through their respective internal and external threads as one. In order to have a better guiding effect, there should be an appropriate gap between the outer circle of the guide rod (4) and the inner hole of the upper sleeve (6). Similarly, the outer circle of the guide post (3) and the lower positioning sleeve (2) The inner hole b should have a proper clearance. When in use, you only need to ride the V-shaped buckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com